A control system for electric discharge machining

A control system and electric spark technology, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of prolonged production process, cumbersome process, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

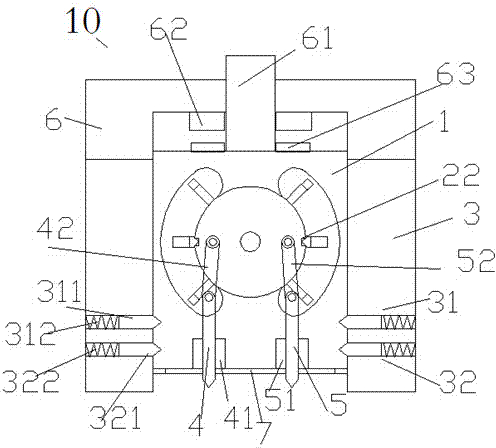

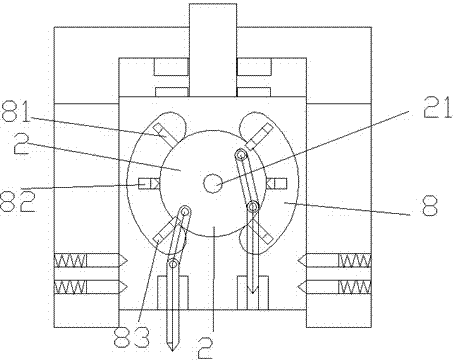

[0028] Refer below Figure 1-5 , describe the present invention in detail.

[0029] An electric discharge machining control system, which includes a controller and an electric discharge machining head device 10, the electric discharge machining head device 10 includes a lower frame 3, an upper frame 6 and an inner frame 1, and the upper frame 6 is in the Above the lower frame 3, the inner frame 1 is located in the chamber formed by the lower frame 3 and the upper frame 6, and can slide up and down;

[0030] Wherein, the upper inner side of the upper frame 6 and the upper side of the inner frame 1 are respectively provided with coupled electromagnetic coils 62 and magnets 63 to drive the sliding of the inner frame 1; The lower part of the side wall is symmetrically provided with an upper wedge surface positioning pin 31 and a lower wedge surface positioning pin 32 in each side wall, and the lower parts of both sides of the inner frame 1 are respectively symmetrically provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com