Strip rolling variable crown roll having local edge wave control capability

A controllable, variable crown technology, used in contour control, roll, metal rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The technical solutions of the present invention will be further described below in conjunction with the embodiments.

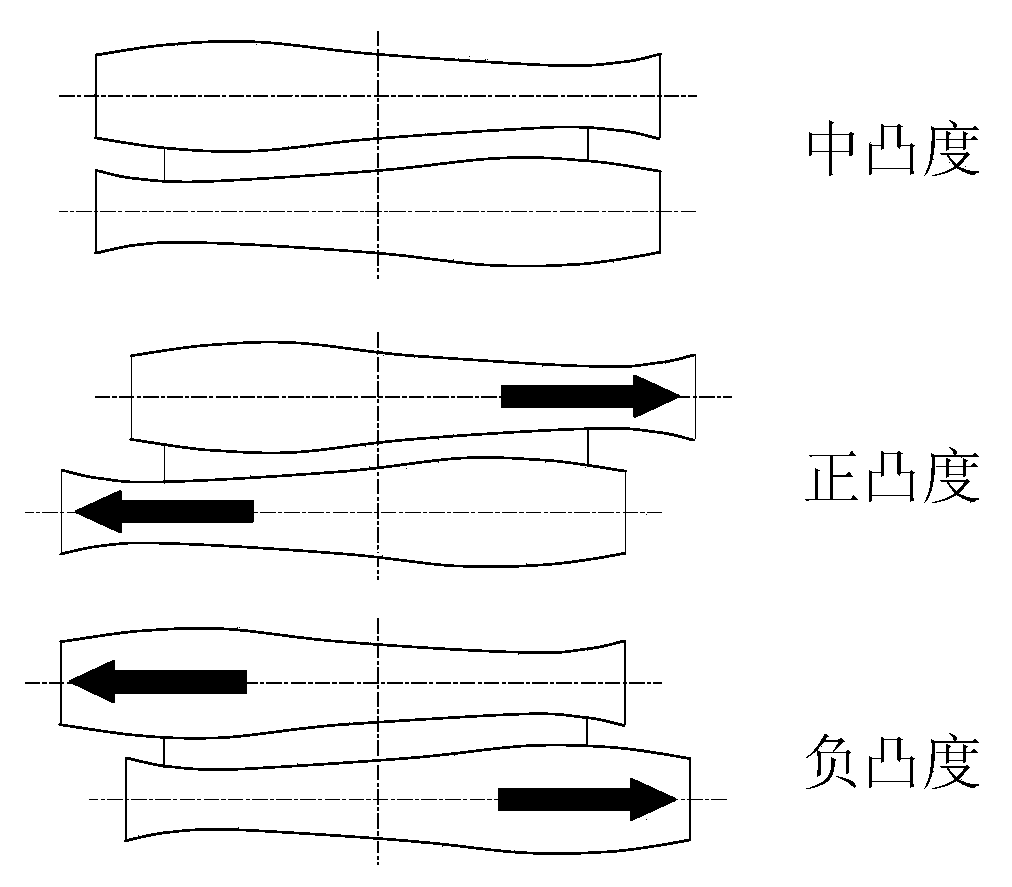

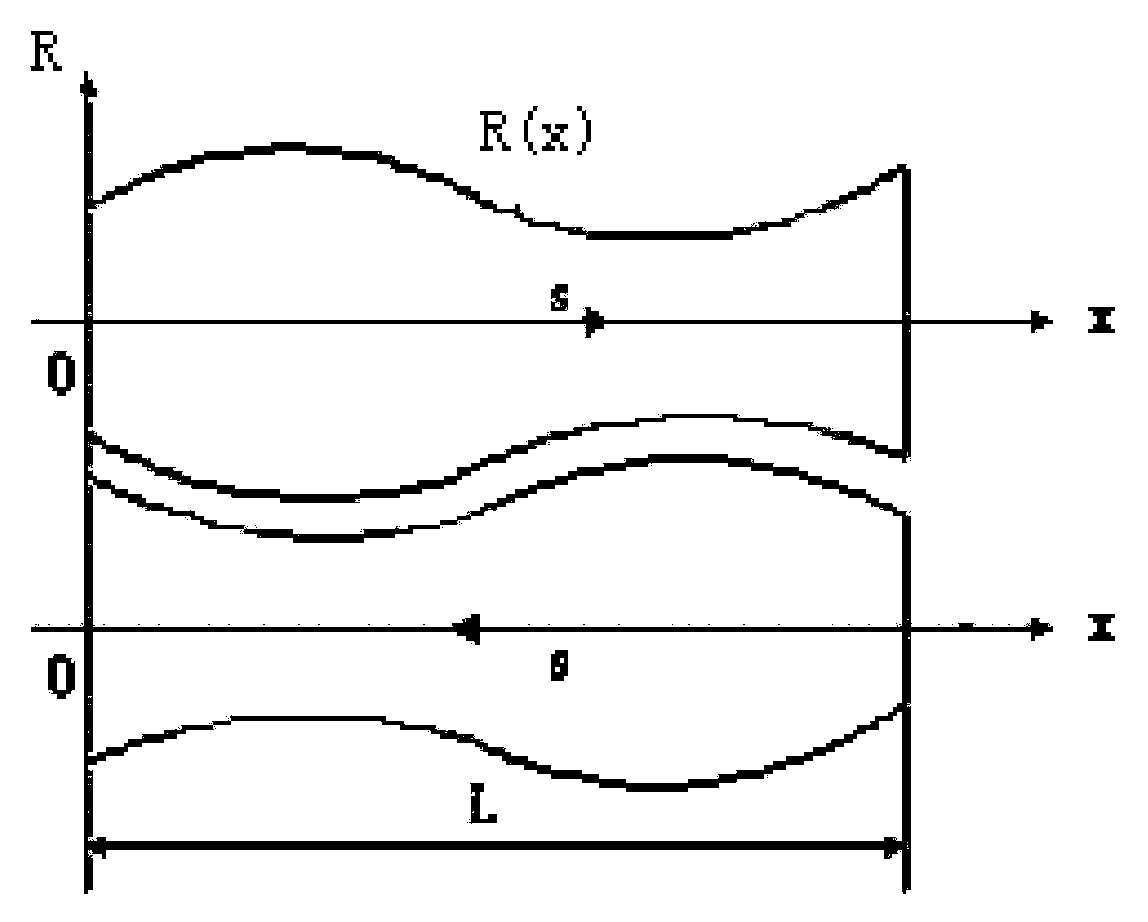

[0072] A variable crown roll with local edge wave control capability, characterized in that the roll shape curve is composed of an edge wave control section and a continuous variable crown section. First, the end of the edge wave control section of the roll body is taken as the coordinate origin Set the roll curve equation as:

[0073] y t 0 ( x ) = R 0 + ( a 1 + a 1 ′ ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com