Tea winnowing machine

An air separator and air separation technology, which is applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of uneven and stable wind speed, waste of energy, waste of resources, etc. The selection machine has simple structure, high wind selection effect, and easy-to-achieve effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

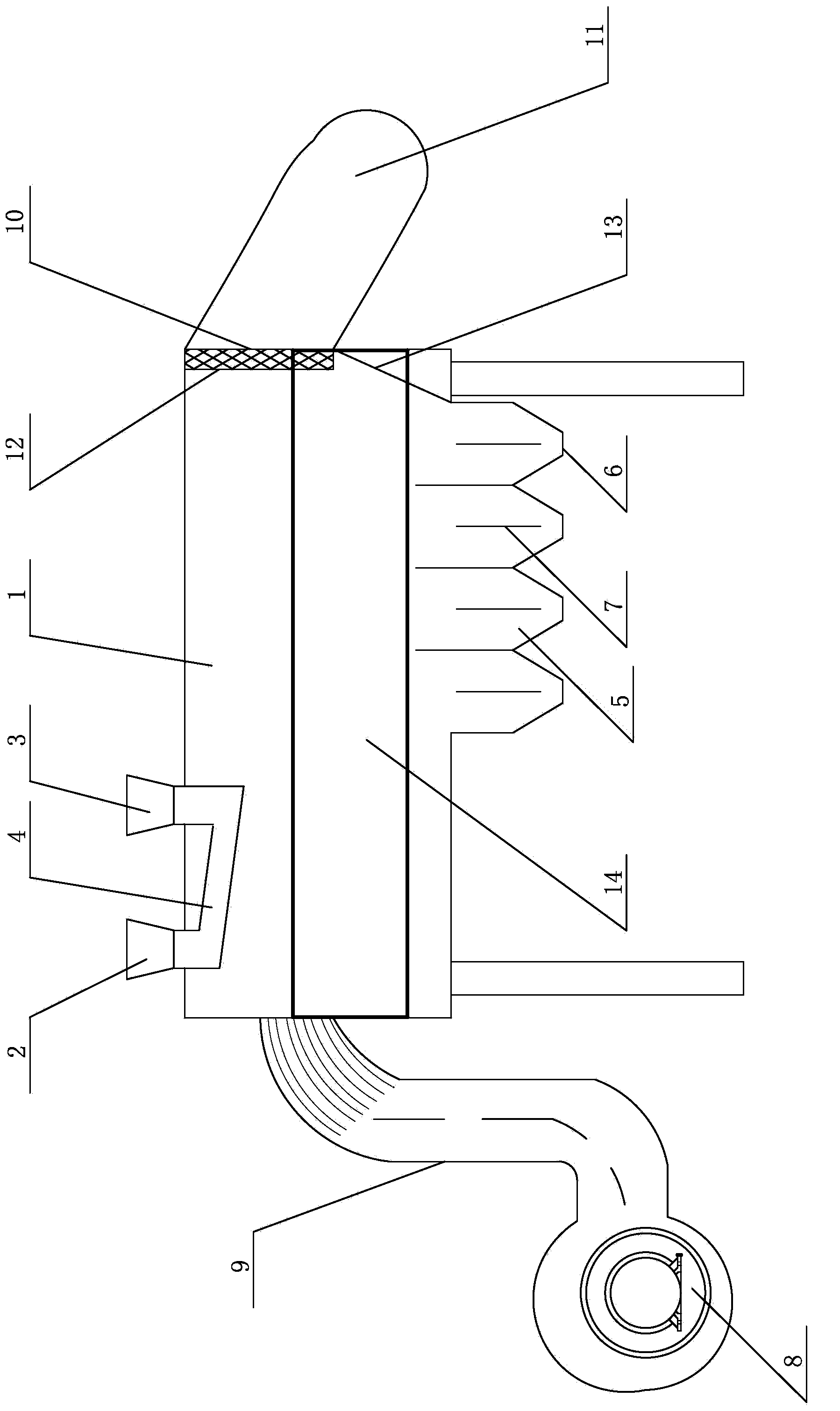

[0022] Such as figure 1 Shown, a kind of tea winnowing machine comprises winnowing room 1, blower fan 8; Communication is through a screening device 4 provided with an oscillator.

[0023] The bottom of the winnowing room 1 is provided with a plurality of tea buckets 5, and the top of the tea buckets 5 is provided with a tea outlet 6, and a swirl plate 7 is fixedly installed above the tea outlet 6, and the swirl plate 7 Stand upright at the center of the tea outlet 5; in this embodiment, it is preferable to set the vertical distance between the bottom of the swirling plate 7 and the tea outlet 6 to be 90-100 cm.

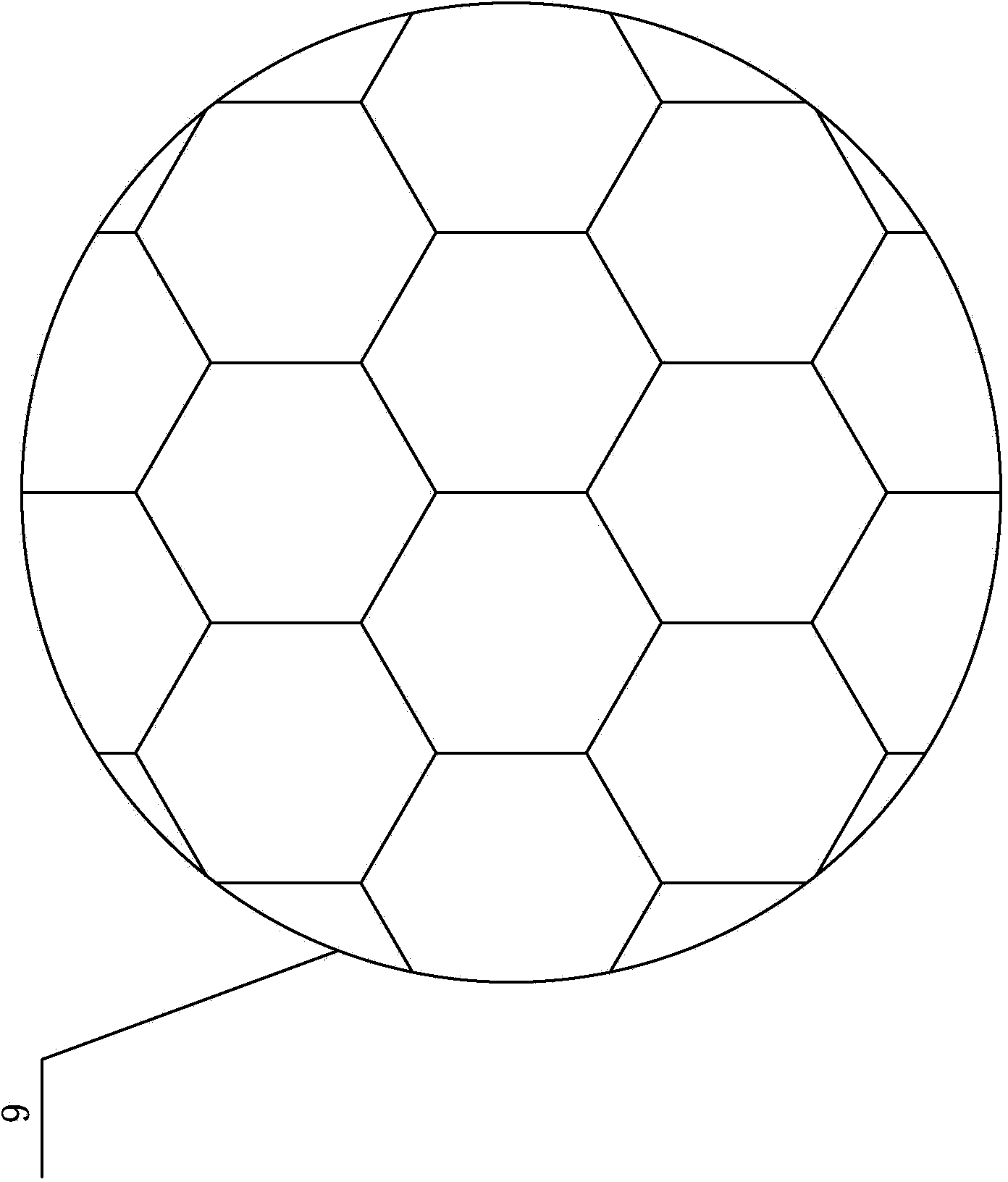

[0024] The left side of the winnowing chamber 1 is connected to the blower fan 8 through the S-shaped pipeline 9, and the installation position of the S-shaped pipeline 9 tuyere is lower than the screening device 4; the present embodiment preferably sets the S-shaped pipeline 9 internal structure design as a honeycomb multi-channel structure, such as figure 2 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com