Tea winnowing machine

A winnowing machine and tea technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems that the quality of winnowing is not as good as that of open models, and achieve ideal wind flow field, High-quality winnowing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

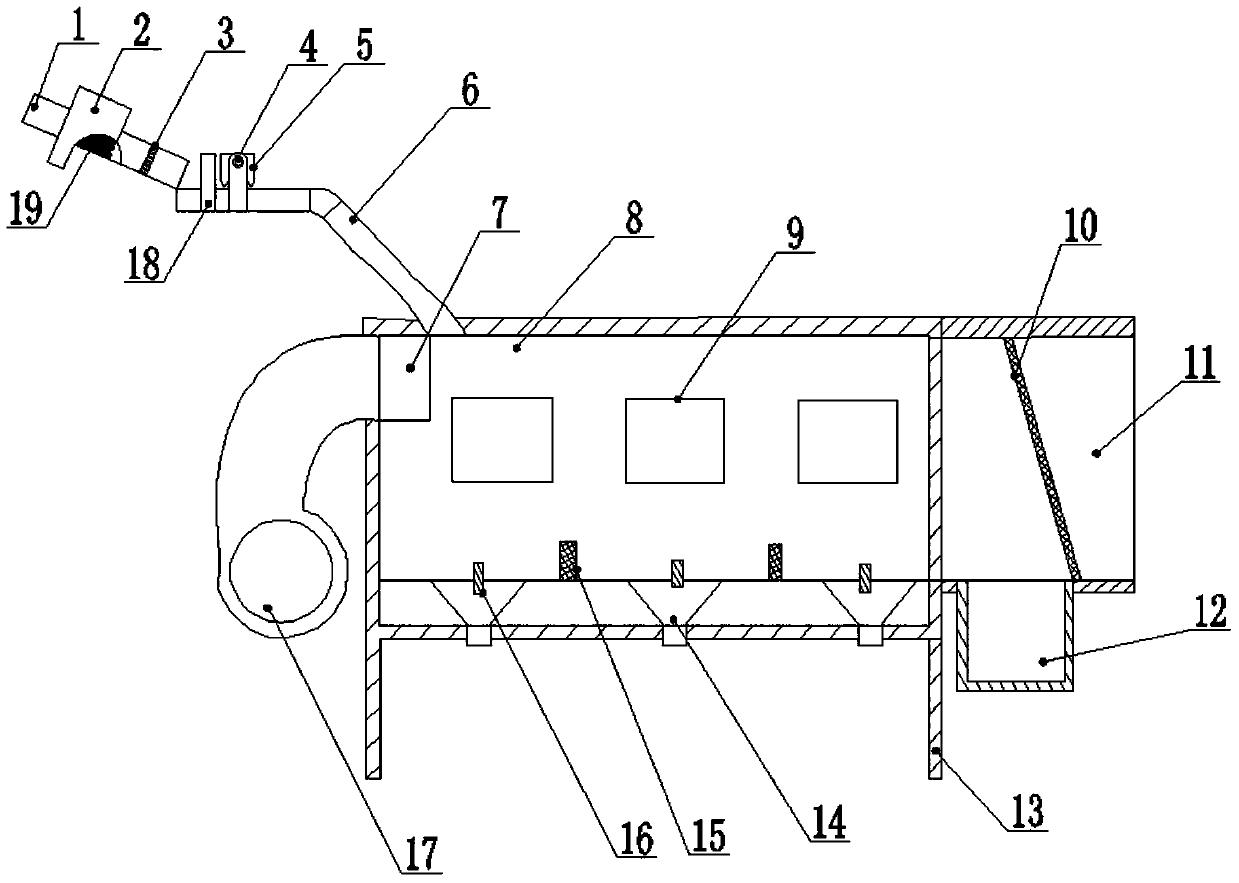

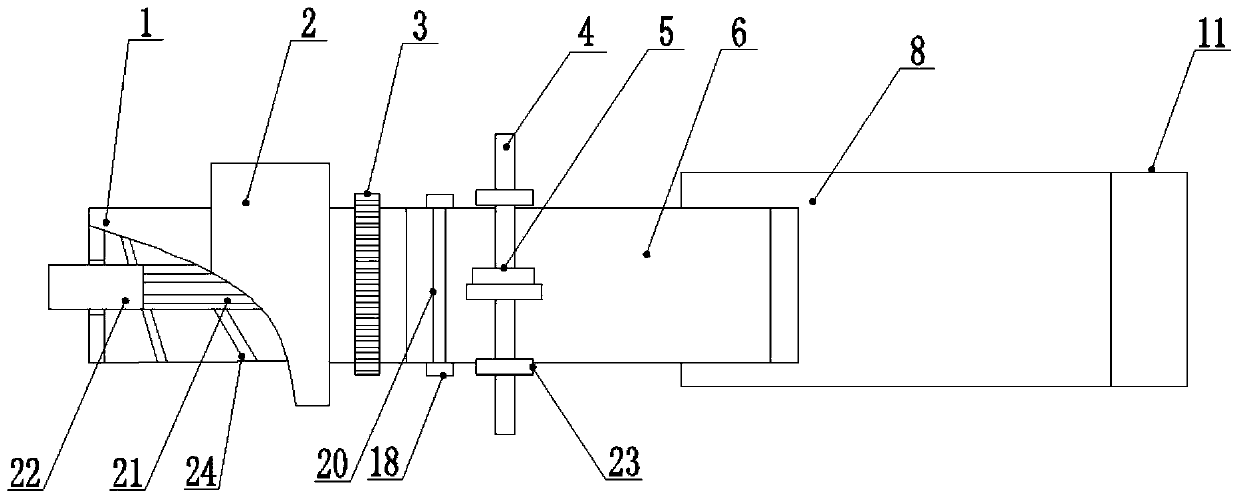

[0022] Such as figure 1 and figure 2 Shown, tea winnowing machine comprises frame 13, winnowing channel 8 and feeding device, and described feeding device comprises negative pressure box, leveling device and conveyer belt, and described negative pressure box comprises negative pressure dedusting chamber 2, and described In the negative pressure dedusting chamber 2, there is a rotary sleeve 1, one end of the rotary drum 1 is provided with a feed port, and the other end of the rotary drum 1 is connected with the conveyor belt 6; the rotary drum 1 is adjacent to the conveyor belt The 6 ends are inclined downward, and the drum wall located in the negative pressure dedusting chamber 2 is evenly arranged with a plurality of screen holes 19, and one end of the drum 1 is provided with a rotating ring gear 3, and the drum 1 is rotated and installed There is a stirring device; the stirring device includes a rotating shaft 22, and the rotating shaft 22 is rotatably mounted on one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com