Novel grain winnowing device

A technology of grain and winnowing, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of no reliable sorting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

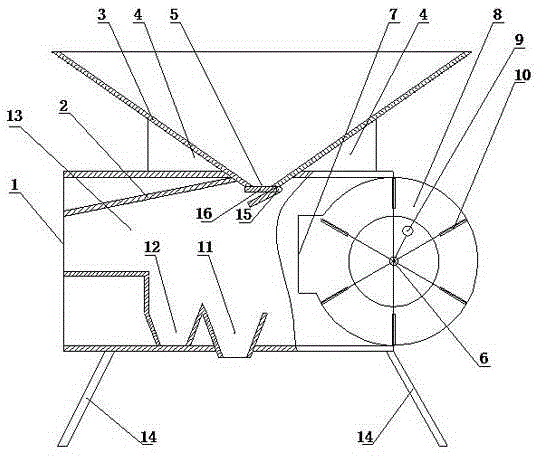

[0012] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0013] figure 1 Shown is the structure of novel grain winnowing device, comprises sorting box 13, material box 3, and material box 3 is arranged on the top of sorting box 13, and material box 3 is inverted cone shape, to provide larger storage space while , is conducive to the automatic sliding of grain to the feed port 5; one side of the sorting box 13 is provided with an air outlet 1, and the other side is provided with an air supply part 8, and the air supply part 8 is cylindrical, and the air supply part 8 is provided with rotating shaft 6 along the axial direction, and rotating shaft 6 is provided with blade 10, and one end of rotating shaft 6 stretches out air-supply part, and is provided with crank 9 on the section that rotating shaft 6 stretches out air-supply part 8, and air-supply part 8 An air outlet 7 is provided,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com