Screen capable of preventing materials from blocking during material processing and self-cleaning method thereof

A self-cleaning and material technology, applied in chemical instruments and methods, filtration, solid separation, etc., can solve the problems of reduced cleaning effect, high energy consumption and ineffectiveness of high-pressure gas, and achieve the effect of cleaning sticky blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

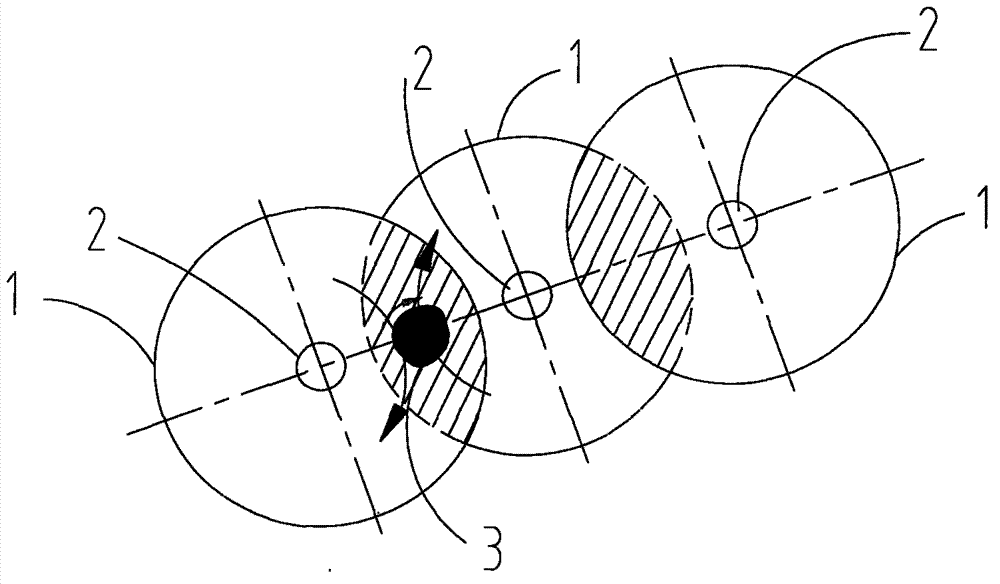

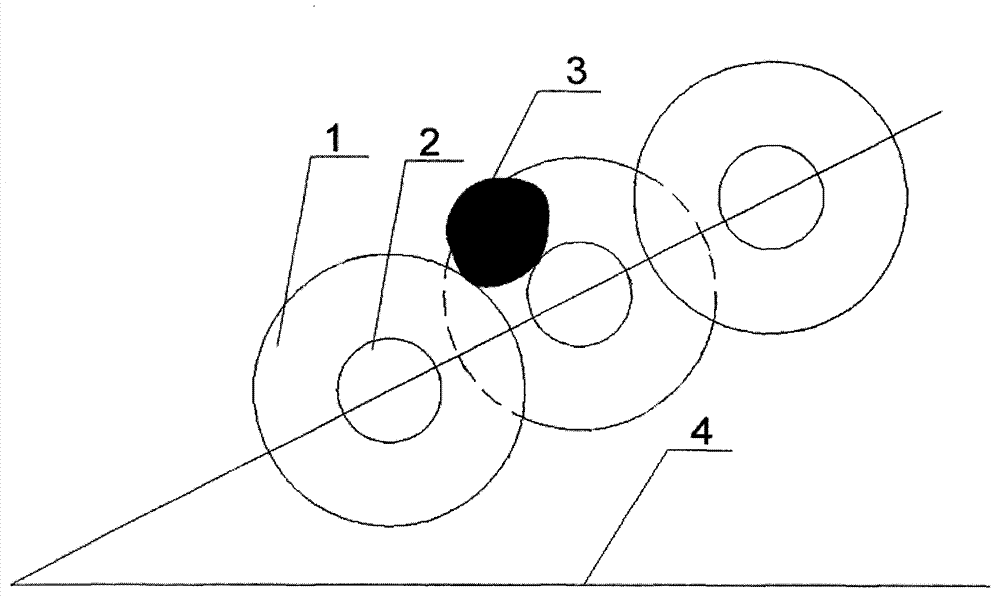

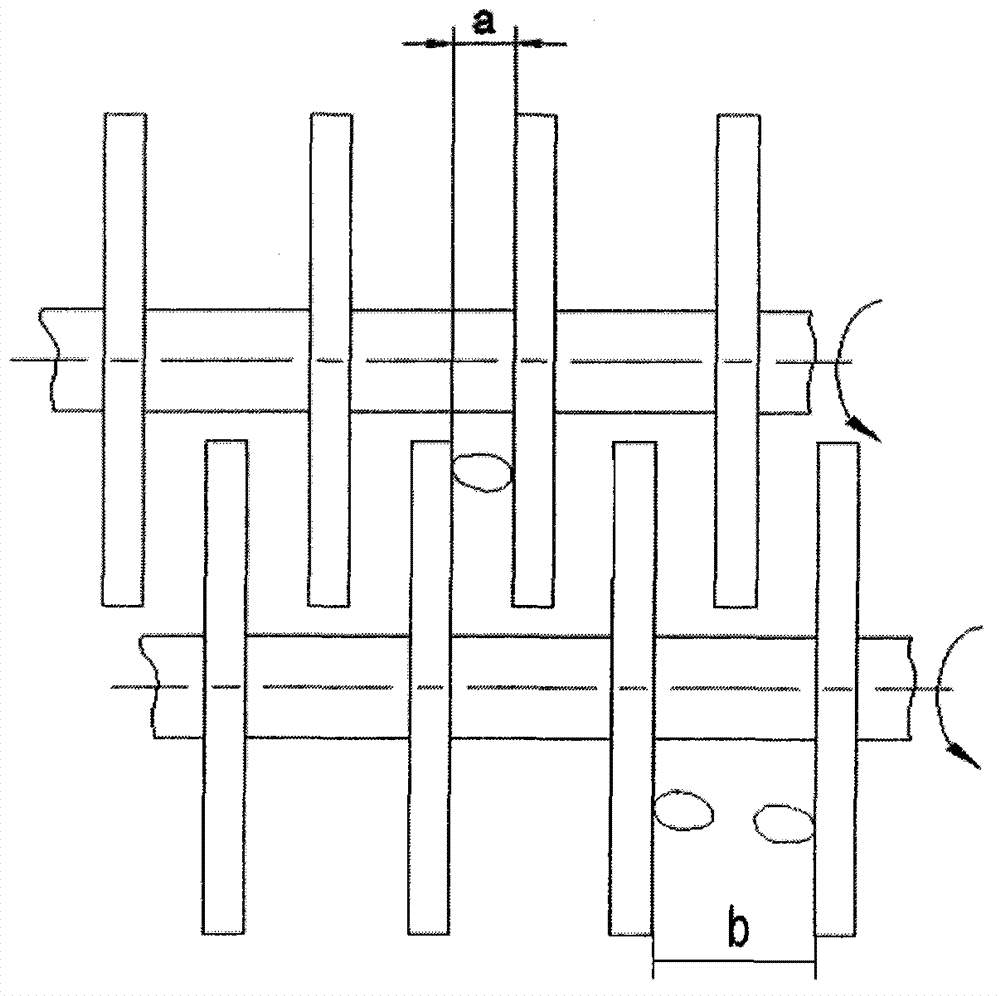

[0018] See attached figure 1 , attached figure 2 And attached image 3 , this embodiment includes a plurality of rotating shafts 2 arranged horizontally or obliquely, a sieve 1 arranged on the rotating shaft 2 and a motor driving the rotating shaft 2 to rotate. Arranged in parallel, the distance between adjacent sieves 1 on the rotating shaft 2 is the same, and the size of each sieve 1 is equal. The sieves 1 on two adjacent rotating shafts 2 are interspersed and arranged alternately, and the gap between the sieves 1 forms a sieve hole that can allow materials to pass through. The interspersed alternate setting means: each rotating shaft 2 is equipped with a certain gap of sieves 1, the sieves 1 on two adjacent shafts 2 are alternately interspersed with each other, and the sieves 1 on one rotating shaft 2 are inserted into the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com