Manganese-loaded oxide zeolite and application of manganese-loaded oxide zeolite in treatment of formaldehyde wastewater

A technology of oxide and zeolite, which is applied in the direction of oxidized water/sewage treatment, chemical/physical process, water/sludge/sewage treatment, etc., can solve the problems of high cost, high use temperature, poor stabilizer and moisture resistance, etc. Achieve the effect of superior recycling performance

Active Publication Date: 2015-01-07

BINZHOU UNIV

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Manganese oxide has a catalytic oxidation effect on formaldehyde, but due to the poor stabilizer and moisture resistance of the manganese oxide catalyst, it is mainly used for the removal of formaldehyde gas indoors, but the use temperature is high, or the complete removal of formaldehyde at room temperature can be achieved by loading precious metals ,higher cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment.

[0021] Unless otherwise specified, the reagents and methods involved in the following examples and experiments are all conventional techniques in the prior art.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Login to View More

Abstract

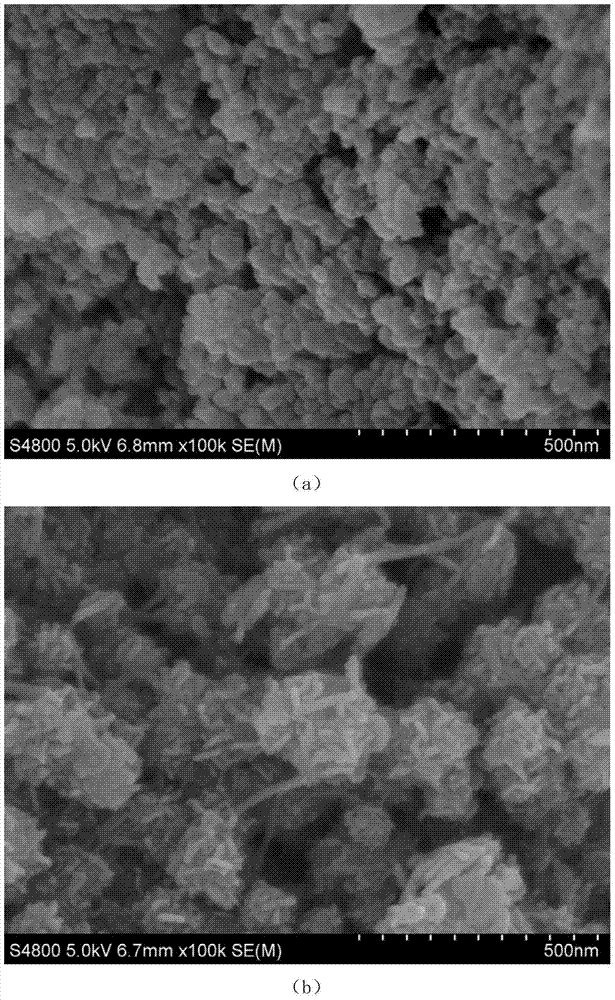

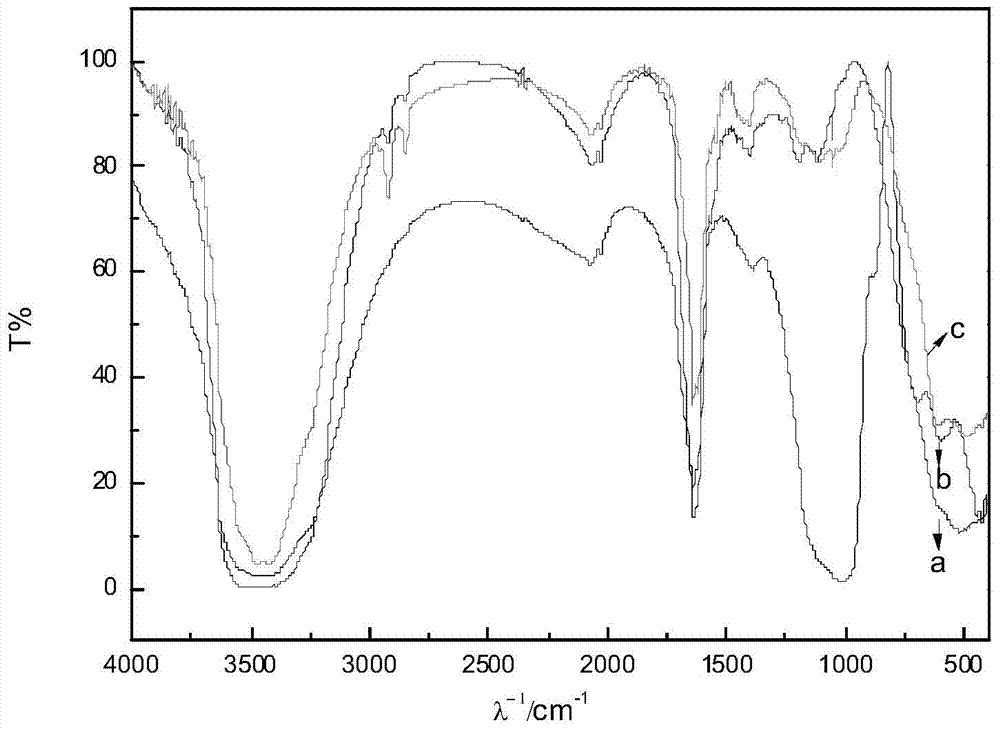

The invention discloses manganese-loaded oxide zeolite which is prepared by the following steps: adding 1.0g of artificial zeolite into 40mL of a potassium permanganate solution with the concentration of 0.40mol / L, and stirring for 30min; then adding 5.00mL of oleic acid drop by drop, and performing reaction at a temperature of 120 DEG C for 12 hours; after the reaction, cooling to reach a room temperature, performing suction filtration, washing by using distilled water and absolute ethyl alcohol in sequence, and drying at a temperature of 60 DEG C for 10 hours to obtain the manganese-loaded oxide zeolite. Experiment shows that the manganese-loaded oxide zeolite disclosed by the invention is a high-efficiency formaldehyde removing agent which can directly oxidize formaldehyde into water and carbon dioxide; the removal rate on the formaldehyde with the concentration of 1 percent is 74.5 percent, and the removal capacity is 4,133mg / g. The manganese-loaded oxide zeolite is stabilized at a pH value of 4-10, and the recycling performance is perfect; after the manganese-loaded oxide zeolite is repeatedly used for three times, the removal capacity on the formaldehyde with the concentration of 1 percent can still reach 3,500mg / g, and the dissolving amount of manganese is smaller than an international limit value being 2.0mg / L.

Description

technical field [0001] The invention relates to a manganese oxide-loaded zeolite, its preparation method, and its application as a formaldehyde remover in treating formaldehyde wastewater. Background technique [0002] Formaldehyde is an important basic chemical raw material, which is widely used in industries such as pharmaceuticals, leather, plastics, textiles, and coatings, resulting in a large amount of formaldehyde-containing wastewater, some of which are high-concentration formaldehyde wastewater, with a formaldehyde content of up to tens of grams per liter. Formaldehyde has been determined by the World Health Organization as a carcinogenic and teratogenic substance. How to treat formaldehyde wastewater, especially high-concentration formaldehyde wastewater, has gradually become a research hotspot. Formaldehyde solution is a true solution with high toxicity, poor biodegradability and difficult disposal. At present, the treatment methods of high-concentration formalde...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J29/076C02F1/72C02F101/34

Inventor 李晶贾冬梅李长海姚海波

Owner BINZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com