Preparation process of honey powder

A preparation process and technology of honey powder, applied in the field of food deep processing, can solve the problems of difficult low temperature, unsuitable long-term storage, color, aroma and taste cannot be preserved to the greatest extent, and achieve the effect of low processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The preparation process of honey powder of the present invention comprises the steps of pretreatment, concentration, drying and pulverization, specifically comprising:

[0013] A. Pretreatment: Take the raw honey, add ethanol with a volume ratio of 1 to 3 times, dilute and dissolve below 60°C to obtain a honey solution;

[0014] B. Concentration: Concentrate the honey solution at a pressure below 0.07MPa and a temperature below 60°C to obtain a thick paste with a relative density of 1.0~1.5;

[0015] C. Drying: Dry the thick paste at low temperature to obtain the target product;

[0016] D. Grinding: Grinding and sieving the primary target object obtained after drying to obtain the target object honey powder.

[0017] The concentration of ethanol described in A step is 70~95%.

[0018] The concentration described in step B is one of vacuum heating concentration, direct reverse osmosis concentration, ultrafiltration and reverse osmosis combined membrane concentration. ...

Embodiment 1

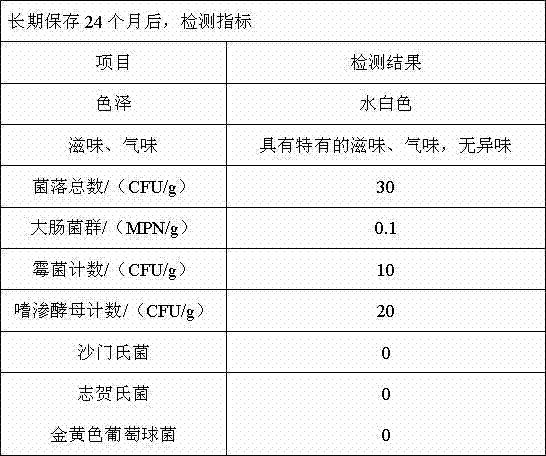

[0031] Take 3000g of honey, add 4500ml of edible ethanol to dilute it into a honey solution at a low temperature (below 60°C), use a vacuum heating concentrator to control the liquid temperature below 60°C and concentrate it into a thick paste, and use a vacuum drying oven to control the product temperature below 60°C to dry. Discharging, milling. Long-term storage without deterioration, the color, aroma and taste are well preserved, and the test results are as follows:

[0032]

Embodiment 2

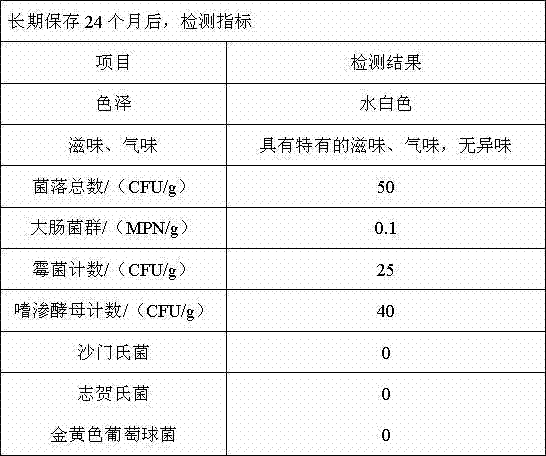

[0034] Take 3,000g of honey, add 5,000ml of edible ethanol to dilute it into a honey solution at low temperature (below 60°C), concentrate it into a thick solution by direct reverse osmosis, pump it into a belt vacuum dryer, and spread it on the drying belt. The belt speed is 15cm / min, the vacuum degree is controlled at 0.078-0.081MPa, the temperature of the material in the first, second and third stages is controlled below 60°C, and the cooling temperature in the fourth stage is controlled at 25°C for continuous drying and discharging , milling powder. Long-term storage without deterioration, the color, aroma and taste are well preserved, and the test results are as follows:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com