Non-contact rock sound wave speed detection method

A sonic speed, non-contact technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems of destroying the integrity of the core, manpower and time consumption, etc., to facilitate research, improve reuse rate, and reduce repeated mining The effect of the number of cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

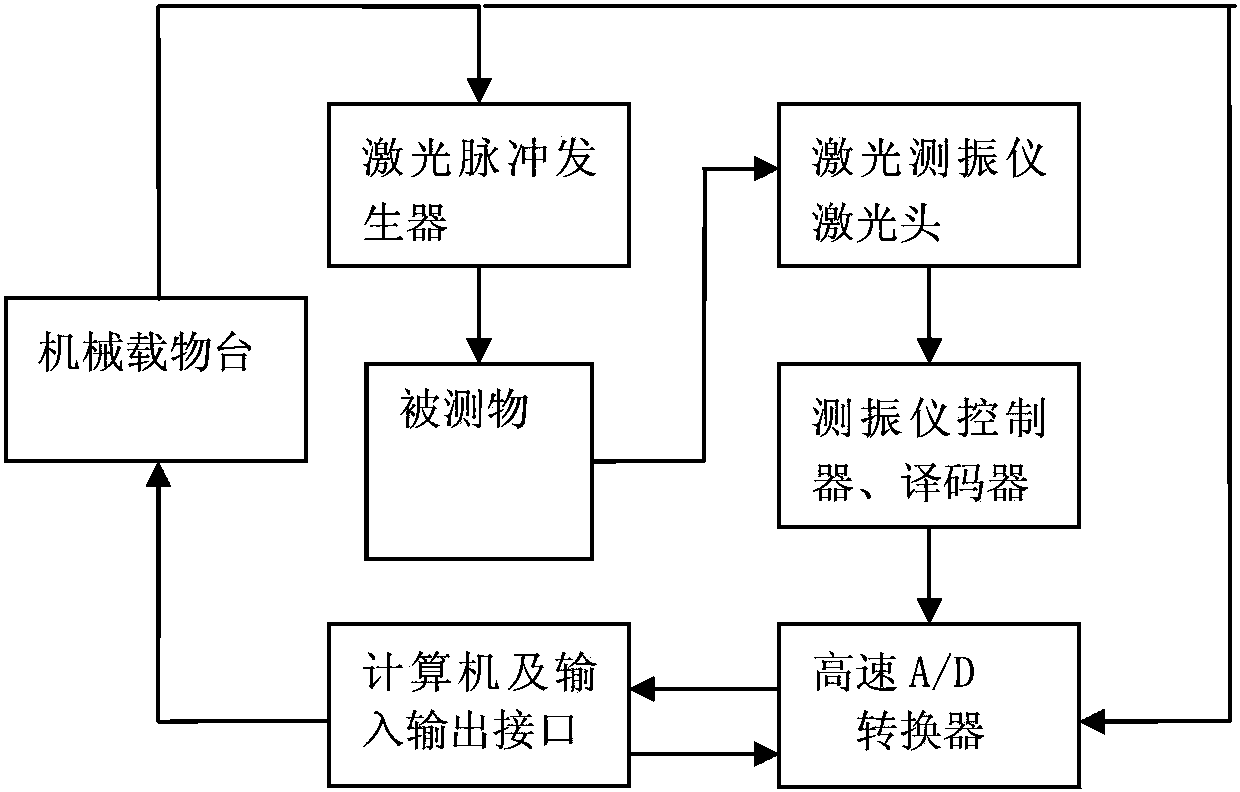

[0040] Below in conjunction with accompanying drawing, the present invention is described in further detail:

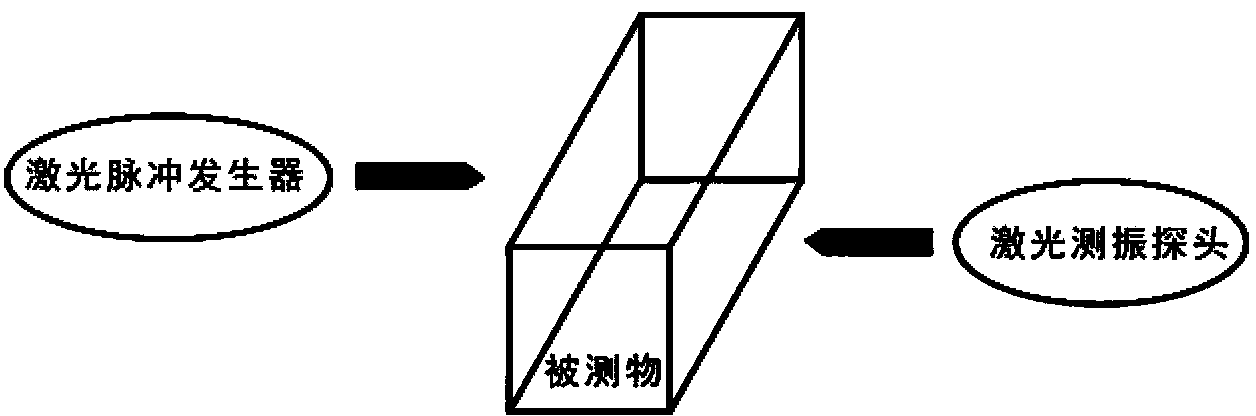

[0041] Such as image 3 As shown, the present invention generates laser pulses through a laser pulse generator, bombards the surface of a measured object, and forms elastic waves-ultrasonic waves in solids. At the same time, on the other side of the measured object, the laser head of the laser vibrometer is used to test the vibration of the surface of the measured object, and the vibration signal is passed through the signal converter (referred to as image 3The vibrometer controller, decoder and high-speed A / D converter in the vibration meter) convert the recorded vibration signal into an electrical signal and transmit it to the computer. The researchers draw the electrical signal into an ultrasonic waveform through a computer (the electrical signal received by the signal converter is drawn into a sine wave curve according to the signal strength-time through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com