Electronic control system for dual-fuel engine

A dual-fuel engine, electronic control system technology, applied in engine control, combustion engine, internal combustion piston engine, etc., can solve the problems of high emission index, not meeting the requirements of environmental protection, and inability to flexibly control the amount of pilot diesel. Good effect of emission indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

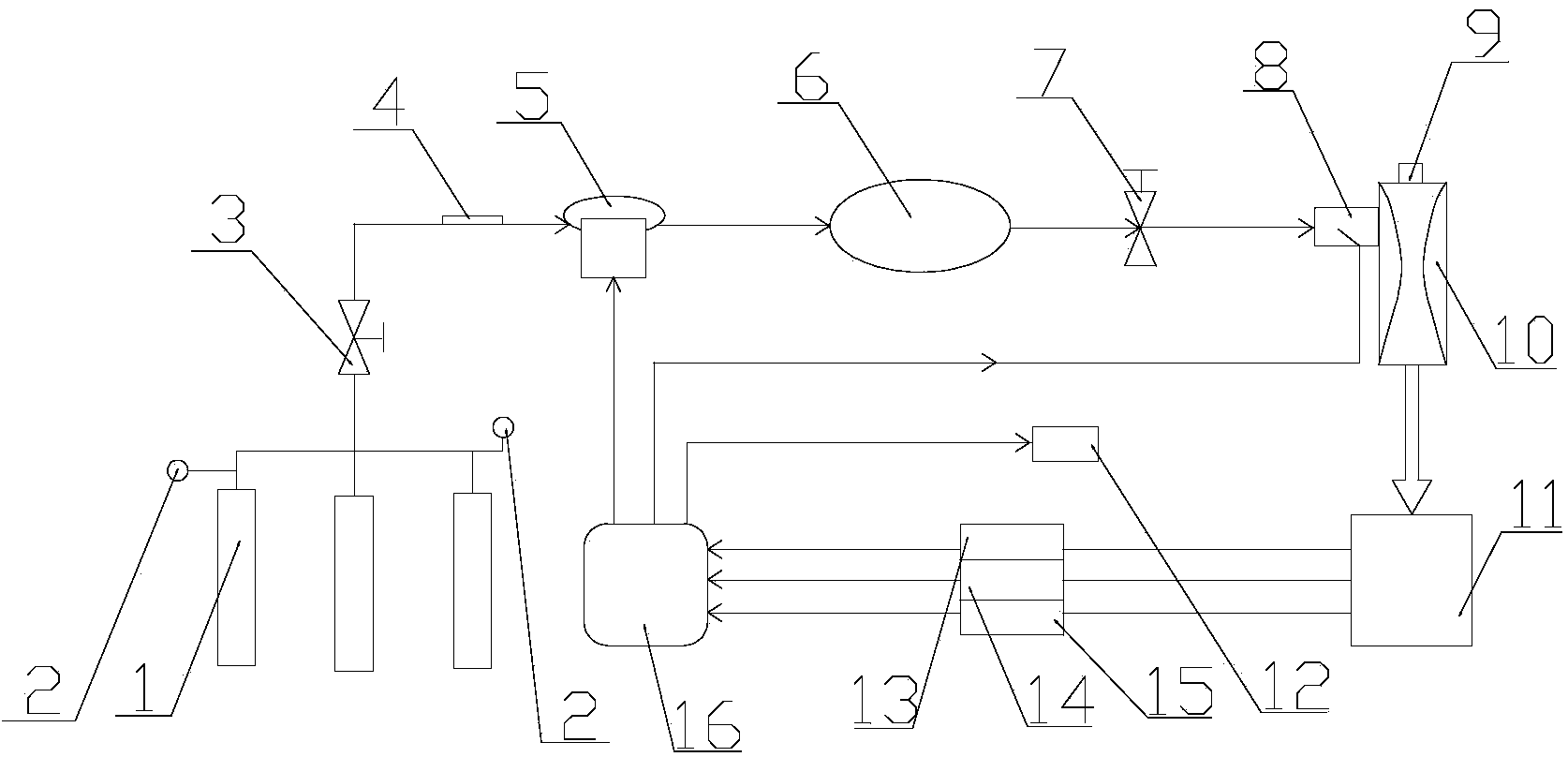

[0009] An electronic control system for a dual-fuel engine, including a CNG cylinder 1, a cylinder pressure gauge 2, a regulating valve 3, a natural gas heater 4, a high-pressure cut-off valve 5, a pressure reducing valve 6, a linear load valve 7, and a stepping motor valve 8 , air inlet 9, mixer 10, engine 11, oil quantity limiting solenoid valve 12, intake pressure sensor 13, intake air temperature sensor 14, engine speed sensor 15 and electronic control unit 16, and the quantity of described CNG cylinder 1 is many One, the gas cylinder pressure gauge 2 is installed at both ends of the CNG gas cylinder 1, the regulating valve 3, the high pressure shut-off valve 5, the decompression Valve 6, linear load valve 7, stepping motor valve 8, the natural gas heater 4 is arranged on the pipeline between the regulating valve 3 and the high pressure cut-off valve 5, the top of the mixer 10 is provided with the air Inlet 9, the mixer 10 is connected to the engine 11, an intake air press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com