Three blade dredging machine

A dredging machine and cutter head technology, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems of secondary pollution of construction waters, inability to achieve accurate positioning and complete cleaning, and inconvenient transportation, so as to improve the cleanliness The effect of silt efficiency and silt concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

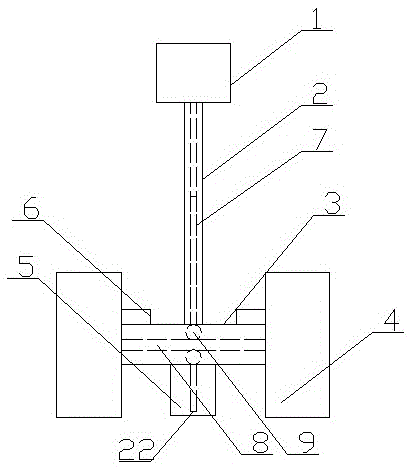

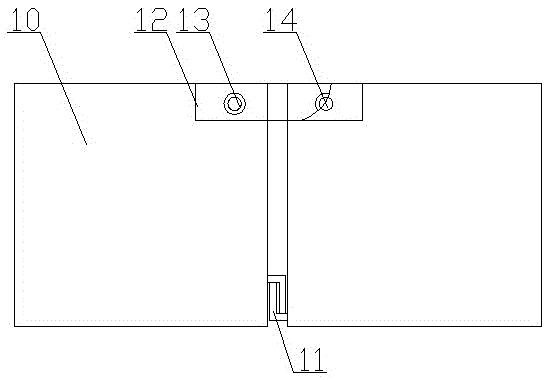

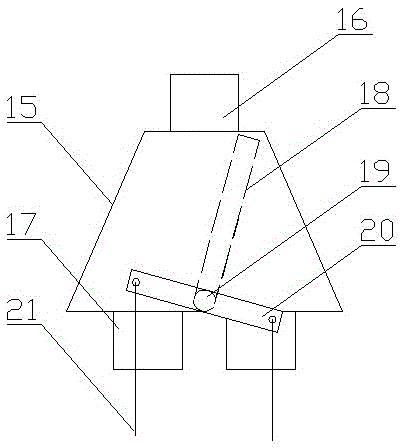

[0021] A three-cutter head dredging machine, including a floating body, a dredging device and a mud discharge device, the floating body includes a plurality of floating body units 10 and a connecting plate 12, and the lower part of the connecting surface of the adjacent floating body units 10 is provided with a facing Up or down the right-angled clasp 11, the upper part of the adjacent outer surface of the two floating body units 10 is provided with a pin hole 14, and the connecting plate 12 is connected to the sides of the two adjacent floating body units, and the connecting plate 12 is provided with There is a connection hole corresponding to the pin hole 14, and a pin 13 is installed in the connection hole; the dredging device includes a row frame 2 and a power unit 1, and the tail end of the row frame 2 is installed on the bow of the ship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com