Antibacterial peptide fermentation culture medium formula

A fermentation medium and antibacterial peptide technology are applied in the field of antibacterial peptide fermentation medium prescription, and can solve the problems of long fermentation period, high cost, easy generation of bubbles in the medium and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

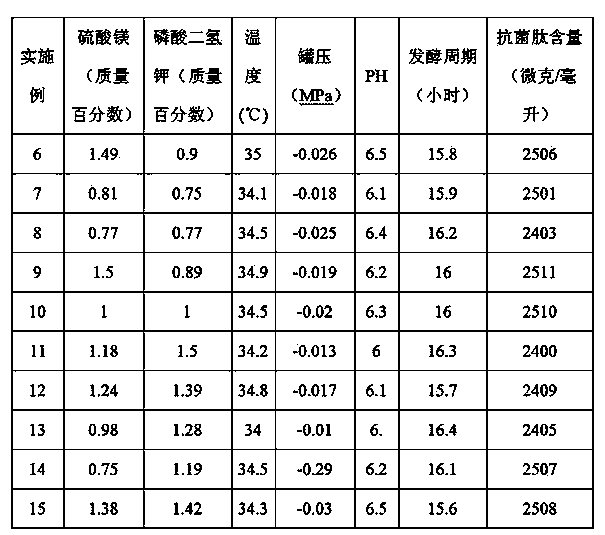

Examples

Embodiment 1

[0009] Inoculate a Bacillus subtilis on the culture medium, the medium formula is: 2% corn steep liquor dry powder, 2% yeast powder, 3% peptone, 1%-1.5% magnesium sulfate, 1%-1.5% potassium dihydrogen phosphate, The rest is soft water. Industrially, the process conditions for inoculating the strains on the medium of the formula of the present invention for fermentation are: fermentation temperature 34-35°C, aeration ratio 1:1, tank pressure 0.01-0.03MPa, stirring speed 150 rpm, pH6- 6.5. The fermentation period is 16 hours, and the fermentation liquid with the antimicrobial peptide content of 2490 μg / ml-2510 μg / ml can be obtained.

Embodiment 2

[0011] A kind of Bacillus subtilis was inoculated on the culture medium, and the formula of the culture medium was: 2% corn steep liquor dry powder, 2% yeast powder, 3% peptone, 0.75% magnesium sulfate, 1% potassium dihydrogen phosphate, and the rest was soft water. The fermentation process conditions are: temperature 34°C, ventilation ratio 1:1, tank pressure 0.03MPa, stirring rate 150 rpm, pH 6, fermentation cycle 16.4 hours, and a fermentation broth with an antimicrobial peptide content of 2505 μg / ml.

Embodiment 3

[0012] Embodiment 3: A kind of Bacillus subtilis is inoculated on the medium, and the medium formula is: corn steep liquor dry powder 2%, yeast powder 2%, peptone 3%, magnesium sulfate 1%, potassium dihydrogen phosphate 0.75%, all the other are soft water. The fermentation process conditions are: temperature 35°C, ventilation ratio 1:1, tank pressure 0.01MPa, stirring speed 150 rpm, pH 6.5, fermentation cycle 16.1 hours, and a fermentation broth with an antimicrobial peptide content of 2501 μg / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com