Black-plated steel sheet

A coated steel plate, black technology, applied in the direction of coating, layered products, hot-dip coating process, etc., can solve the problem of reducing the effect of blackening promotion, and achieve the effect of excellent design, excellent retention and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] Using SPCC with a plate thickness of 1.2 mm as a base material, a Zn-coated steel plate containing molten Al and Mg with a plated layer thickness of 3 to 100 μm was produced. At this time, the composition of the coating bath (concentrations of Zn, Al, and Mg) was changed, and 20 types of coated steel sheets having different coating compositions and coating thicknesses were produced. Table 1 shows the composition of the coating bath and the thickness of the coating layer for the 20 types of coated steel sheets produced. In addition, the composition of the plating bath is the same as that of the plating layer.

[0111] Table 1

[0112]

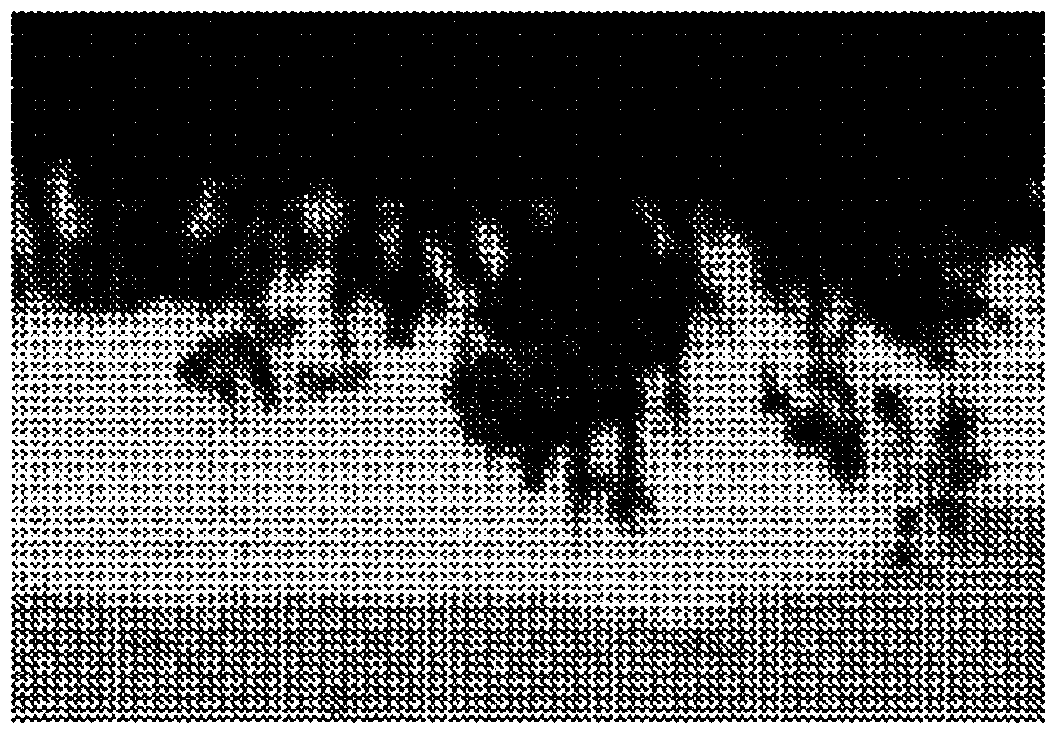

[0113] For the coated steel sheets No. 1 to No. 16, the cross-section of the coating was observed with a scanning electron microscope, and phase identification was carried out by X-ray diffraction. As a result, Al / Zn / Zn can be seen in any coating structure. 2 The ternary eutectic structure of Mg. In addition, Al primary crystals wer...

Embodiment 2

[0141] Using SPCC with a plate thickness of 1.2 mm as a base material, a Zn-coated steel sheet containing molten Al and Mg with a plated layer thickness of 10 μm was produced. At this time, the composition of the coating bath (concentrations of Zn, Al, Mg, Si, Ti, and B) was changed, and 35 kinds of coated steel sheets having different coating compositions were produced. Table 3 shows the composition of the coating bath and the thickness of the coating layer for the 35 types of coated steel sheets produced. In addition, the composition of the plating bath is the same as that of the plating layer.

[0142] table 3

[0143]

[0144]

[0145] The prepared coated steel sheet was placed in a high temperature, high pressure and humidity heat treatment device, and the coating was brought into contact with water vapor under the conditions shown in Table 4.

[0146] For each of the coated steel sheets (Examples 24 to 58) after the water vapor treatment, the cross-section of the...

Embodiment 3

[0154] The coated steel sheet of No. 36 or No. 52 in Table 3 is coated with the inorganic chemical conversion treatment solution shown in Table 5, and is placed in an electric oven without washing with water, and is heated and dried at a temperature of 120° C. An inorganic coating is formed on the surface of the plated steel sheet.

[0155] table 5

[0156]

[0157]

[0158] The plated steel sheet on which the inorganic coating was formed was placed in a high-temperature, high-pressure wet heat treatment device, and the plated layer was brought into contact with water vapor under the conditions shown in Table 6 and Table 7.

[0159] For each of the coated steel sheets (Examples 59 to 90) after the water vapor treatment, the cross section of the coating was observed with an optical microscope. 2 The Mg phase was blackened. In addition, it was confirmed that the partially crystalline Zn 2 Mg phase and Al / Zn 2 Mg Binary Eutectic Zn 2 The Mg phase is also blackened.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| humidity | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com