Sodium bicarbonate product

A sodium bicarbonate product technology, applied in the production field of sodium bicarbonate products, to achieve excellent neutralization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Put 20 g of instant gel BB (gum arabic) into a 2 liter Erlenmeyer flask, and add 2000 ml of deionized water (at ambient temperature), and magnetic flea. Then stir until the instant gel dissolves. The Erlenmeyer flask was placed on a heating plate, and the solution of the instant gel was heated to a temperature of 60° C. while stirring.

[0107] To the hot solution was added (using X-ray diffraction) 100% nahcolite (NaHCO 3 ) to form 290g of commercially available sodium bicarbonate. Stirring was carried out until the sodium bicarbonate was completely dissolved while maintaining the temperature at 60°C.

[0108]The hot solution was spray dried in a Buchi Mini Spray Dryer B-290 with an inlet temperature of 100°C and the following settings.

[0109]

[0110] A "pump %" value of 40 corresponds to a temperature of 55° C. at which the product leaves the drying chamber of the Buchi Mini Spray Dryer.

[0111] Product yield from 2 liters was 193.0 gm = 62.25%.

[0112] (...

Embodiment 2

[0115] Embodiment 2 (comparative example)

[0116] The procedure of Example 1 was repeated except that the "pump %" in the Buchi Mini Spray Dryer was set to 30 which corresponded to the temperature of 85° C. when the product left the drying chamber of the dryer. This is the setting used in the examples of WO2009 / 133409.

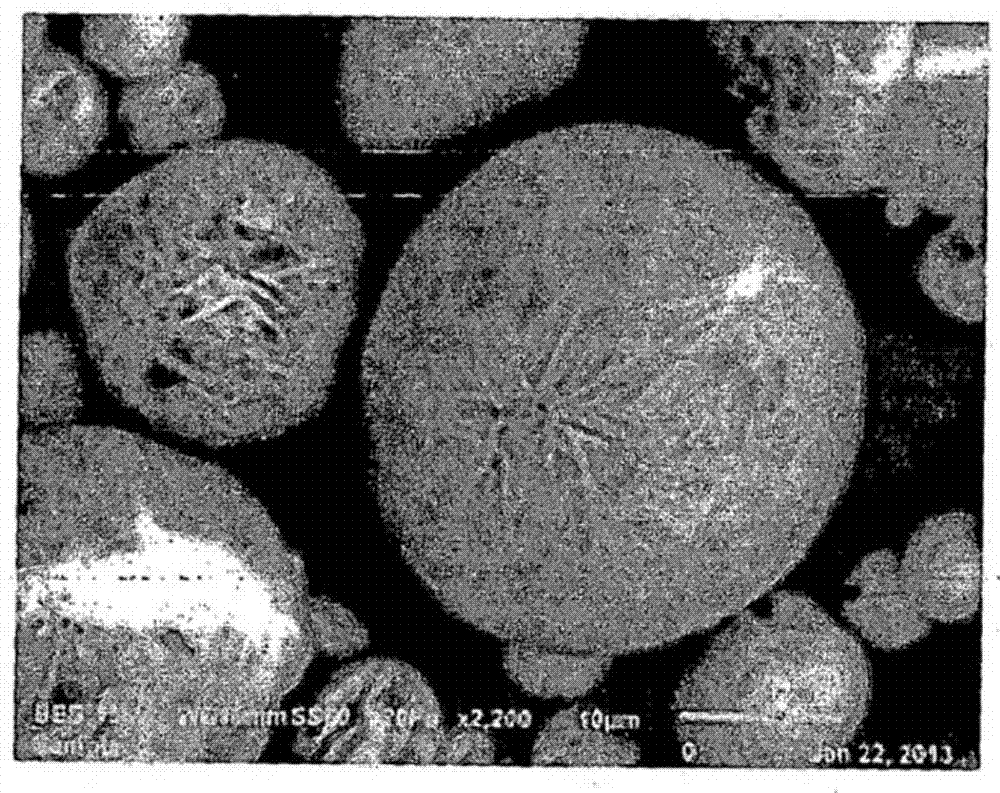

[0117] To illustrate the nature of the product obtained, in Figure 4 Scanning electron micrographs at 2000× magnification are shown in . There are two types of grain in this photo. The larger, smooth spheres (we think) consisted of sodium carbonate formed substantially from the decomposition of sodium bicarbonate during the spray drying process. Another type of particle included sodium bicarbonate, but was smoother in appearance than the particle shown in Figure 1, due (we believe) to the presence of sodium bicarbonate in these particles.

[0118] Analysis by X-ray diffraction determined that the product contained 49% by weight of nahcolite, and 51% by...

Embodiment 3

[0121] Embodiment 3 (comparative example)

[0122] The procedure of Example 1 was repeated, but sodium carbonate was used instead of sodium bicarbonate, and the dissolution of sodium carbonate was achieved at 90°C.

[0123] Afterwards, the resulting solution was spray-dried in a Buchi small spray dryer B-290 under the same conditions as in Example 1.

[0124] 92.4 g of product were obtained in the process, representing a yield of 57.75%.

[0125] Figure 7 1000X scanning electron micrograph of the product obtained. exist Figure 7 As can be seen in , the product is made of roughly spherical balls with uneven appearance. The spheres are solid and not hollow, with an average particle size of 6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com