Metal pad forming method and semiconductor structure

A technology of metal pads and semiconductors, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as poor reliability test results, achieve easy filling, improve performance, and discreteness small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

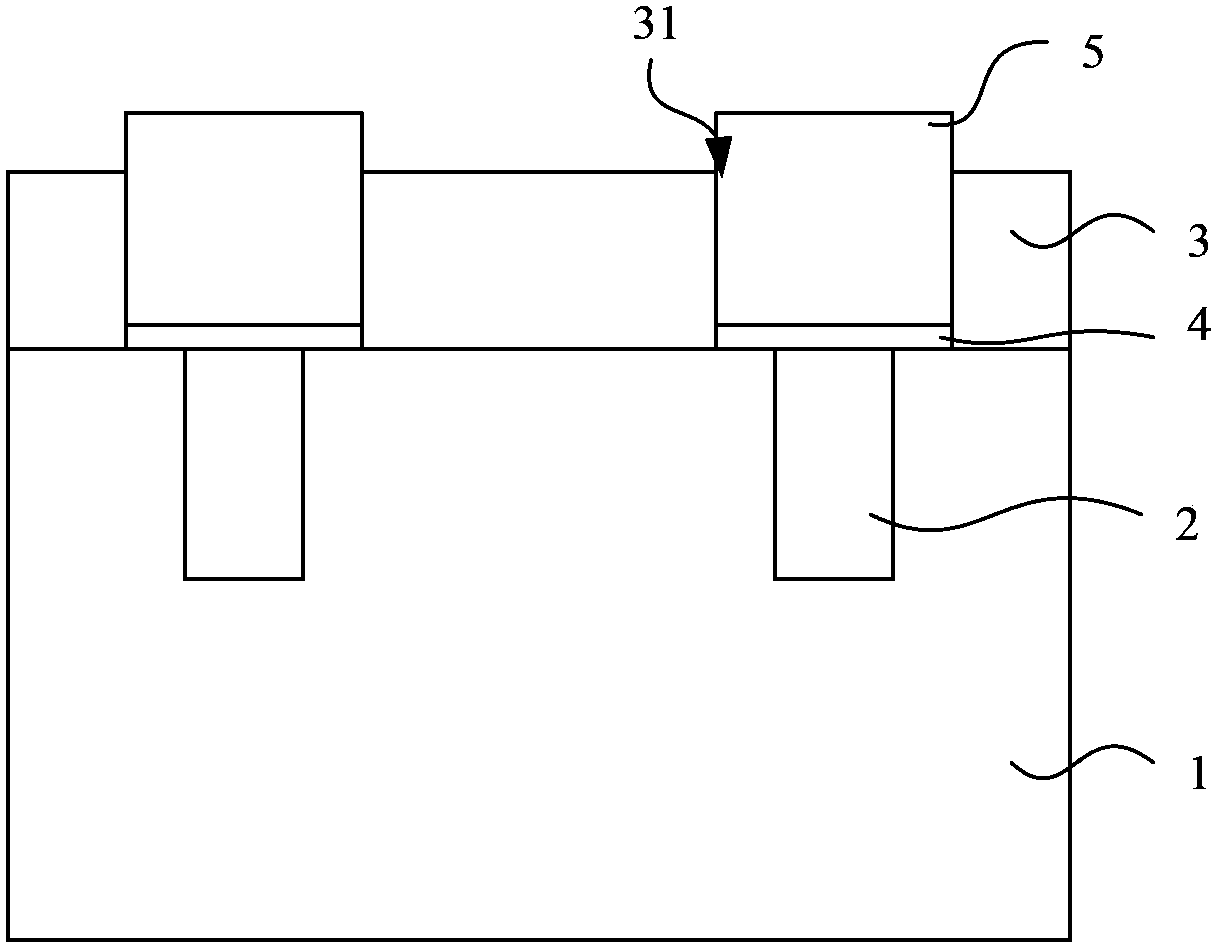

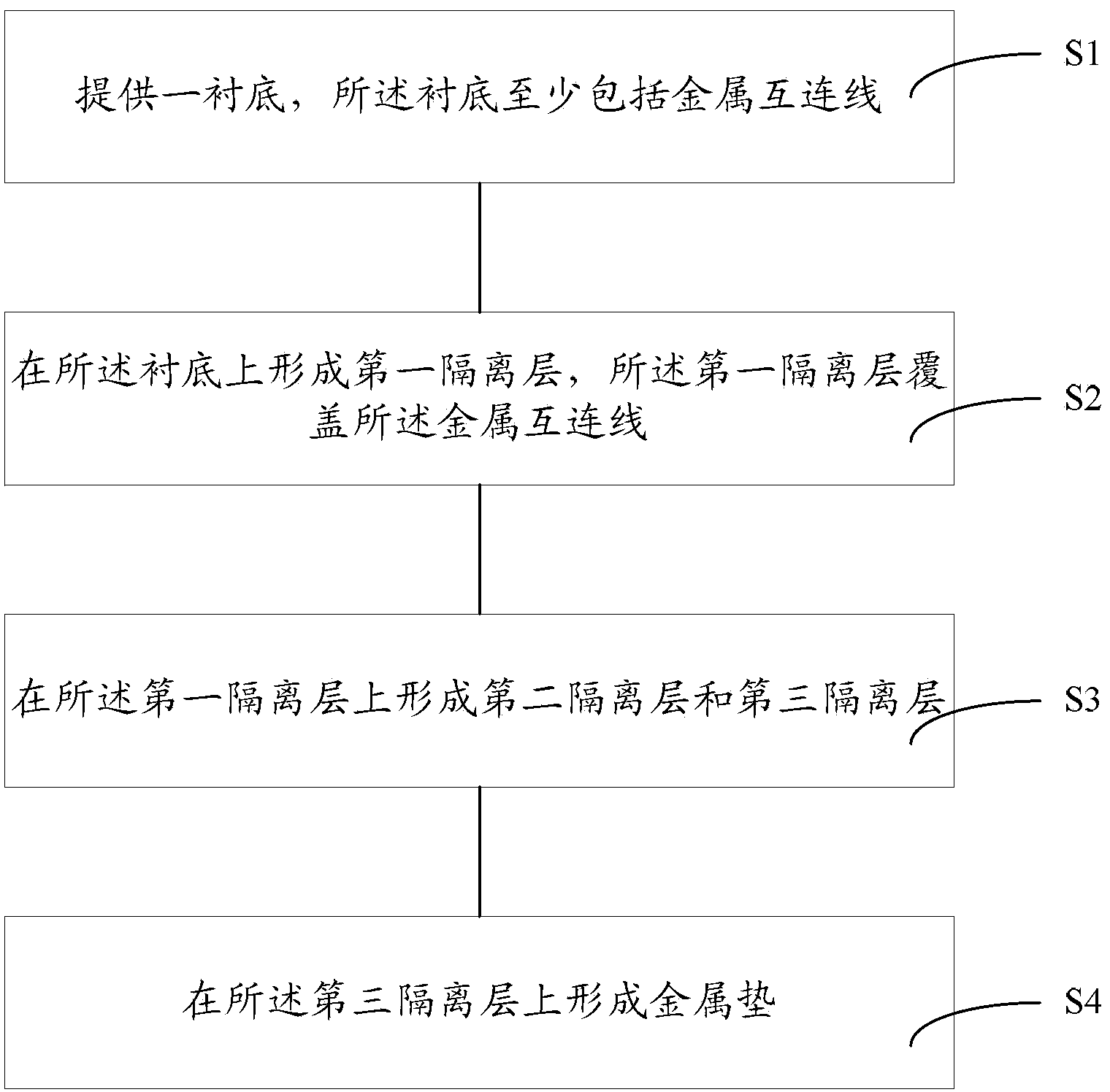

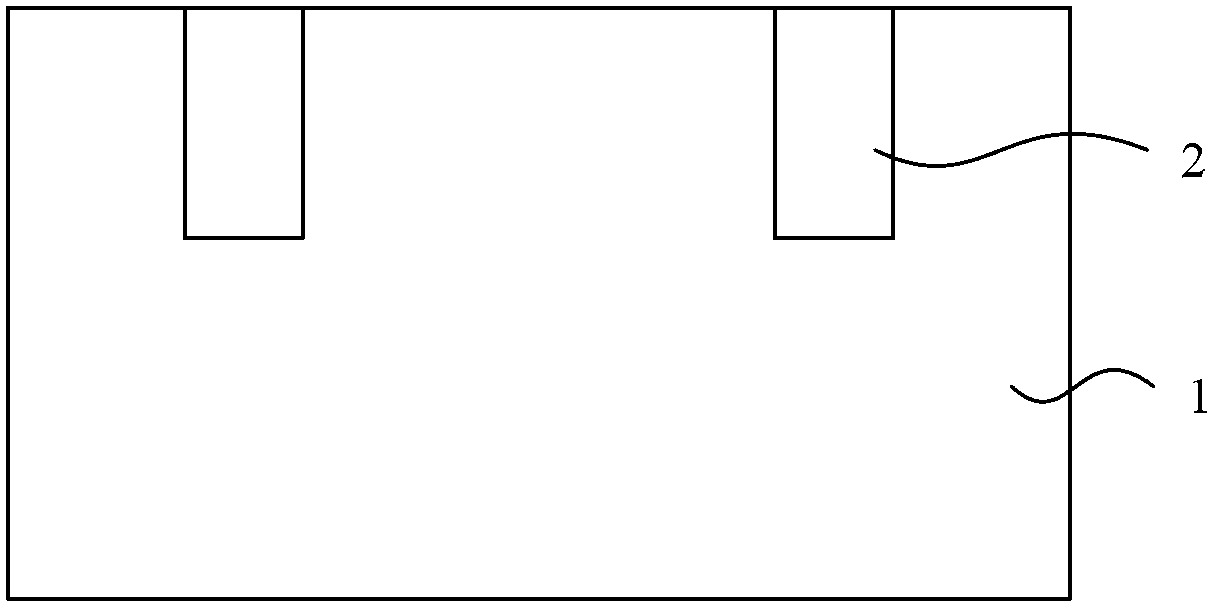

[0033] It has been mentioned in the background art that the potential difference between the two ends of the metal pads in a wafer has a certain difference. At present, it can only be considered that the electrical properties of different regions are different due to process problems. The specific reason is still unclear. After a lot of experiments, the inventor found that after adding titanium (Ti) and titanium nitride (TiN) between tantalum nitride (TaN) as an isolation layer and metal pad aluminum, the measured metal pad of the entire wafer The difference of the potential difference is greatly reduced, which in turn improves the detection pass rate.

[0034] The method for forming a metal pad and the semiconductor structure provided by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The advantages and features of the present invention will become apparent from the following description and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com