Supercritical boiler fire coal heat value self-balance control loop distributed control system implementation method

A decentralized control system and supercritical boiler technology, applied in electrical program control, comprehensive factory control, etc., can solve the problems of long system stability, inability to construct heat signals, large fluctuations in operating parameters of the unit, etc., to improve operating stability and efficiency. economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The implementation platform of this application example is the Emerson OVATION DCS (distributed control) system.

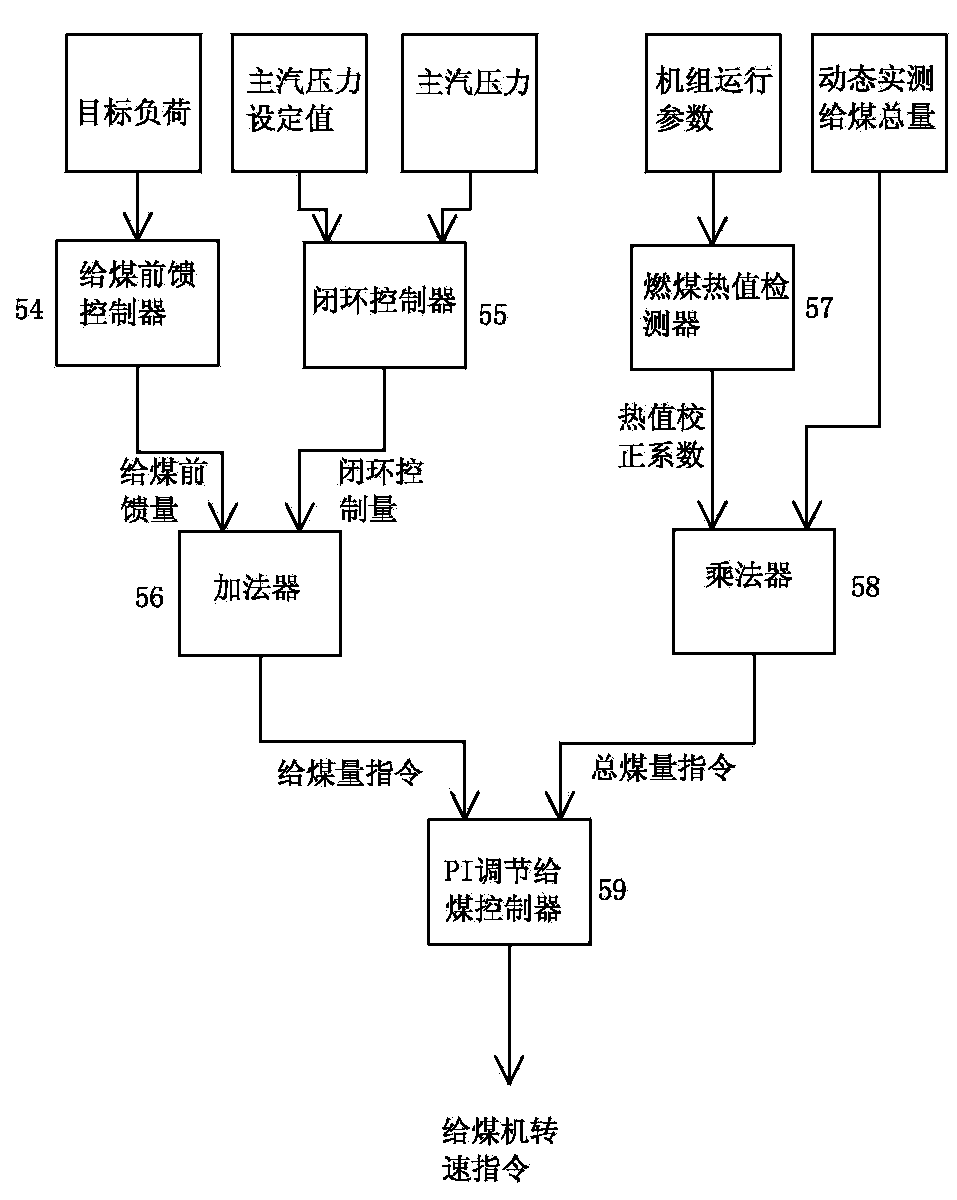

[0049] Such as figure 1 As shown, a supercritical boiler coal-fired calorific value self-balancing control loop decentralized control system implementation method, the method is realized in the automatic control environment, including: the received coal amount instruction and the calorific value corrected total The coal quantity command outputs the final coal feeder speed command through PI adjustment 59; where:

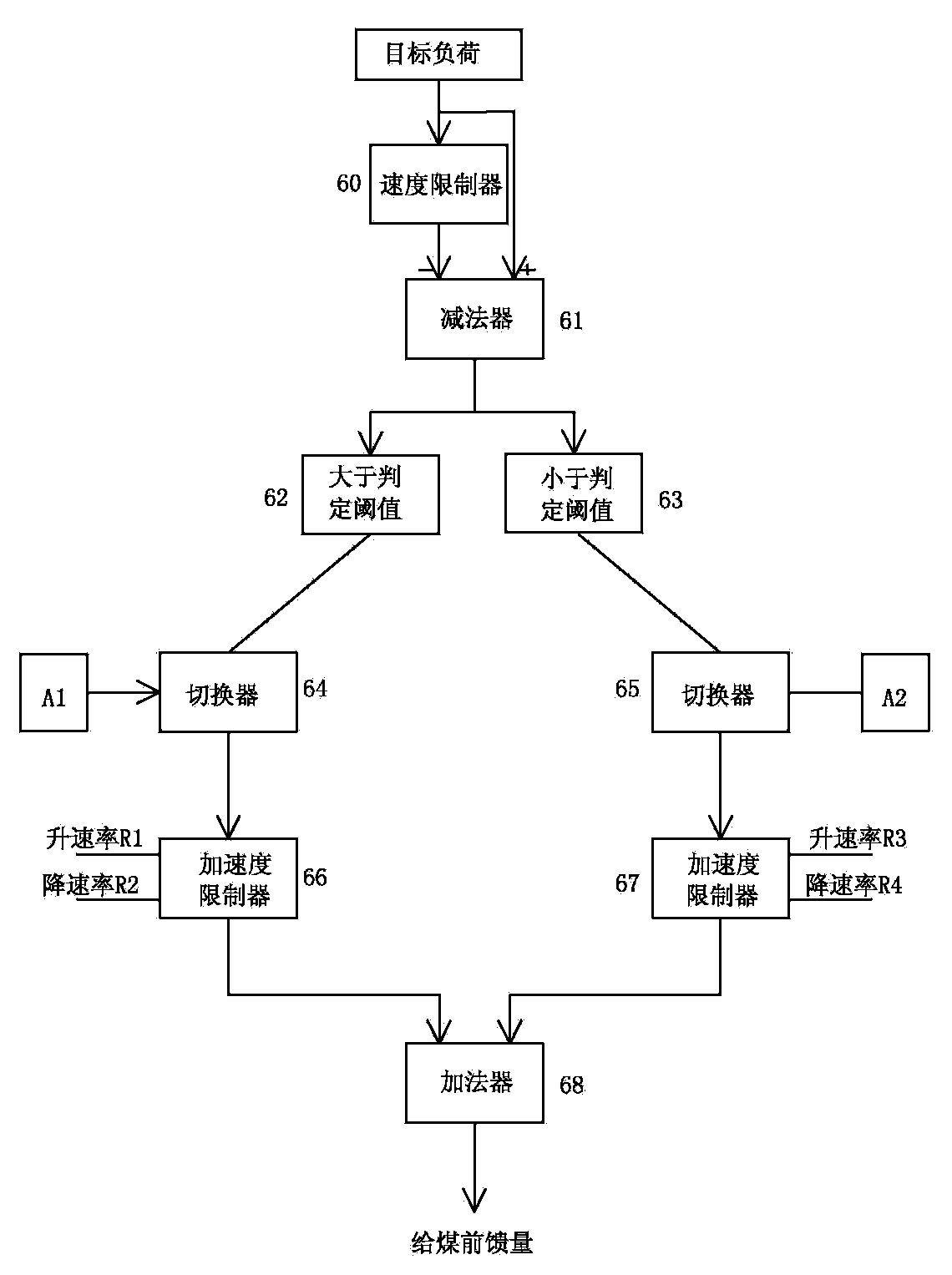

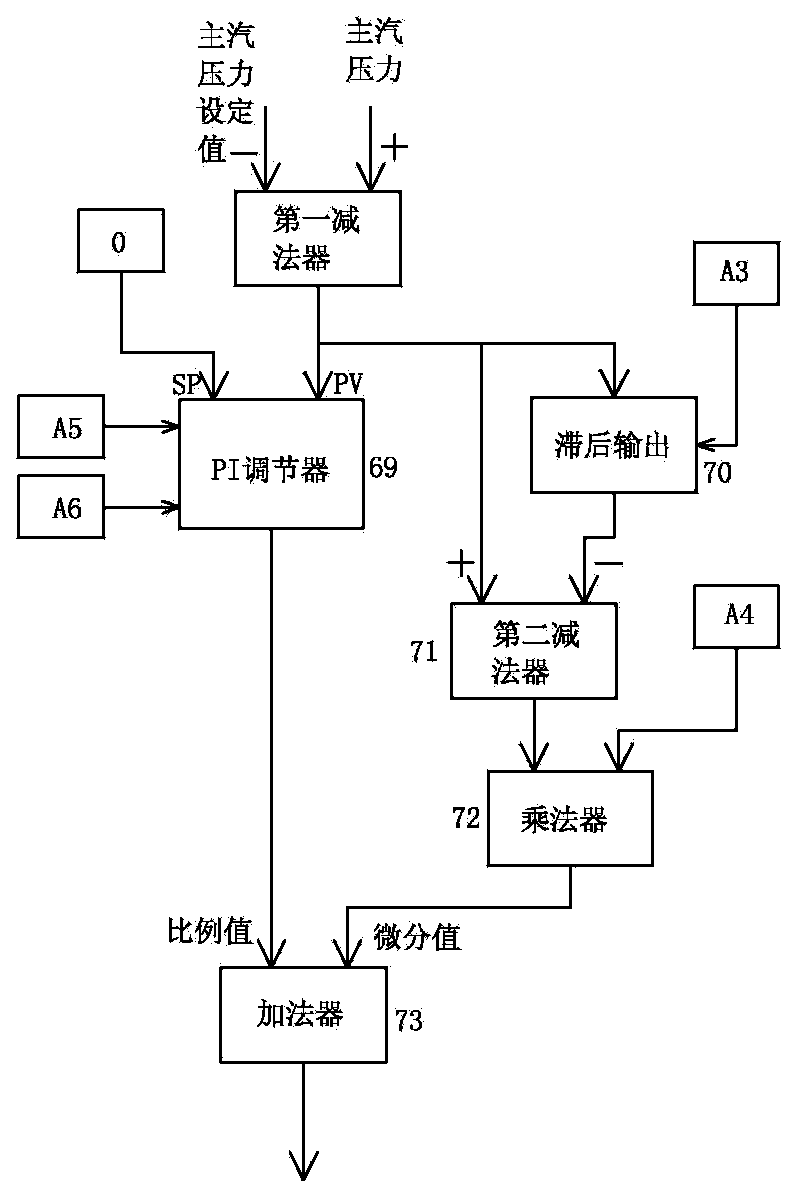

[0050] The coal feed amount command is the coal feed forward amount sent by the target load through the coal feed feed forward generator 54, and the closed loop control amount given by the closed loop controller 55 formed by the main steam pressure setting value and the main steam pressure Coal supply command output after adding 56;

[0051] The total coal quantity instruction after the calorific value correction is the total coal quantity instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com