Multi-view ultrasonic flaw detection system and detection method for steel rail weld joints

An ultrasonic system and ultrasonic flaw detection technology, which are applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc., which can solve the problems of low efficiency, prone to false detection and missed detection, etc. , to achieve the effect of fast operation, beautiful software interface and simple instrument setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The purpose of the present invention is to develop a set of rail weld multi-angle ultrasonic flaw detection system and detection method that meet the requirements of fast detection, effective detection, repeatability, storage of storage results, and post-analysis and processing.

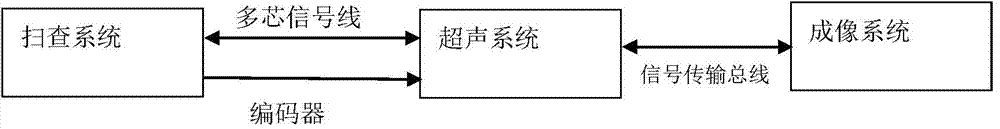

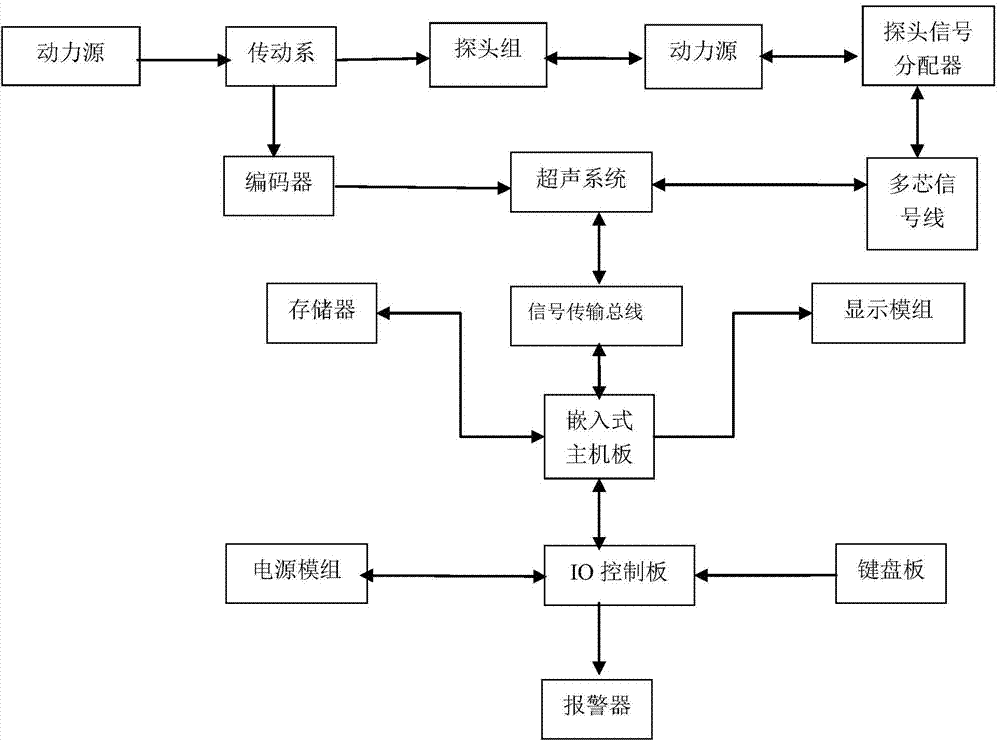

[0042] The overall structure of the system: the embedded host, the hardware architecture of ultrasound acquisition, the signal transmission bus inside the instrument connects the host and the ultrasound system, the operating system of the instrument runs on the host, and the application software runs on the operating system.

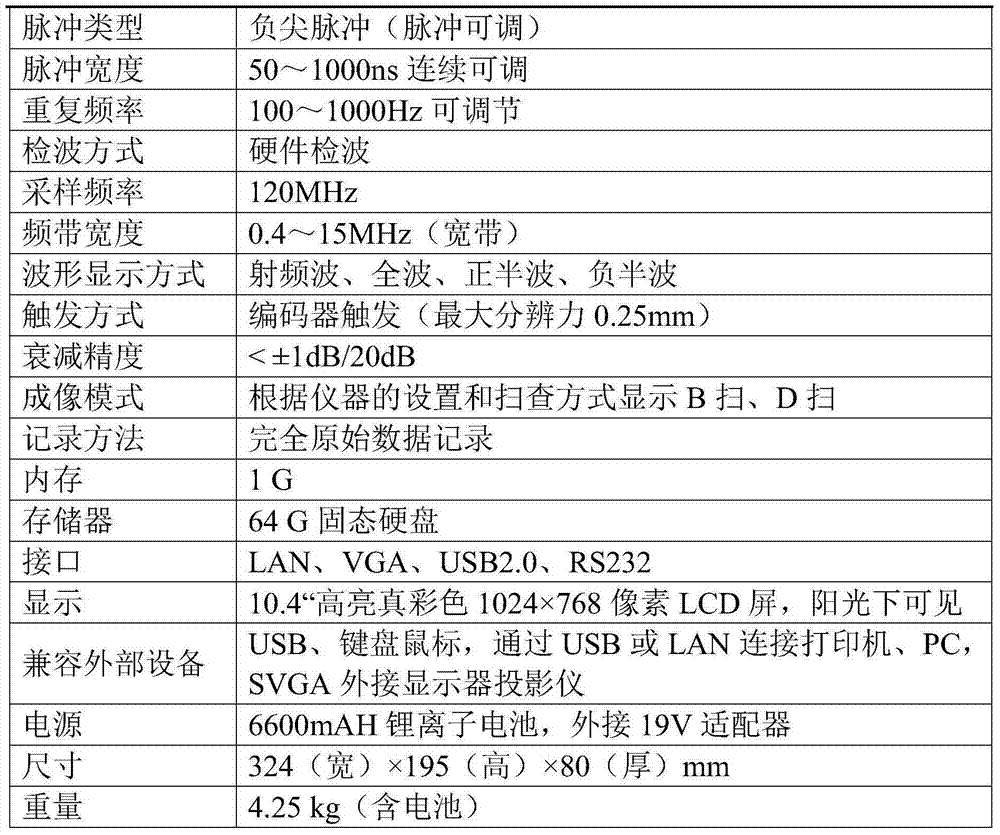

[0043] The embedded host uses an embedded industrial computer motherboard, the ultrasonic board is an 8-channel professional ultrasonic circuit board, the internal bus of the instrument adopts the USB2. software.

[0044] The power module is installed in the casing to provide power supply, and at the same time provide connection and transfer to the main unit, ultrasonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com