Intelligent magnetic induction flux sensor

A flow sensor and electromagnetic induction technology, applied in the field of flow sensors, can solve problems such as long signal transmission distance, complex interface, and susceptibility to interference, and achieve the effects of high circuit reliability, simplified measurement system, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further illustrated in the following examples, which are only used to illustrate the present invention and not to limit the present invention.

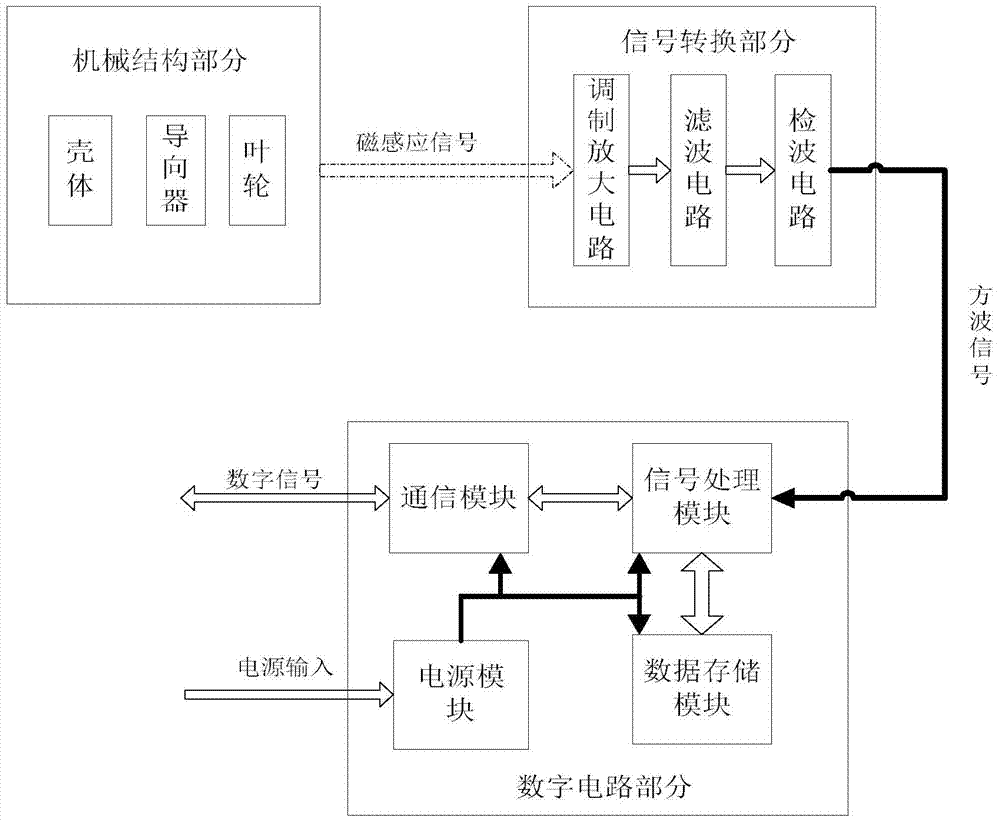

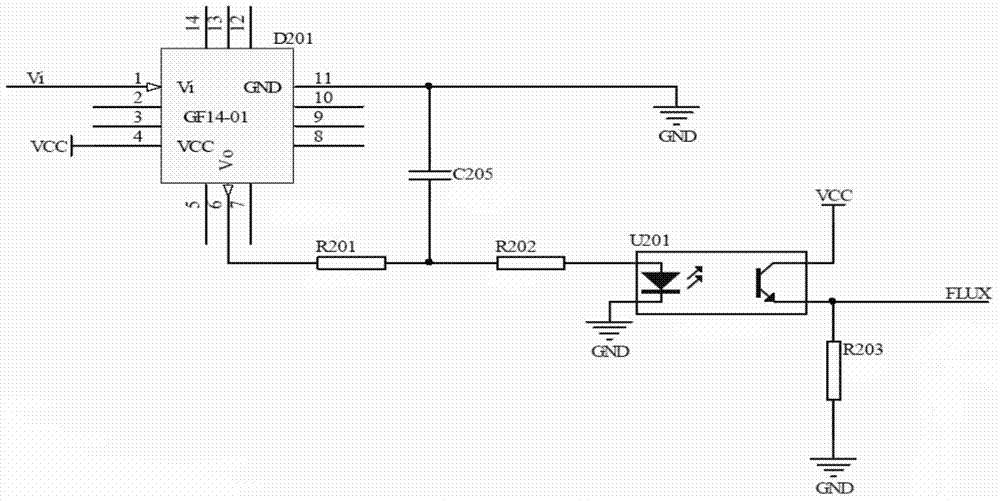

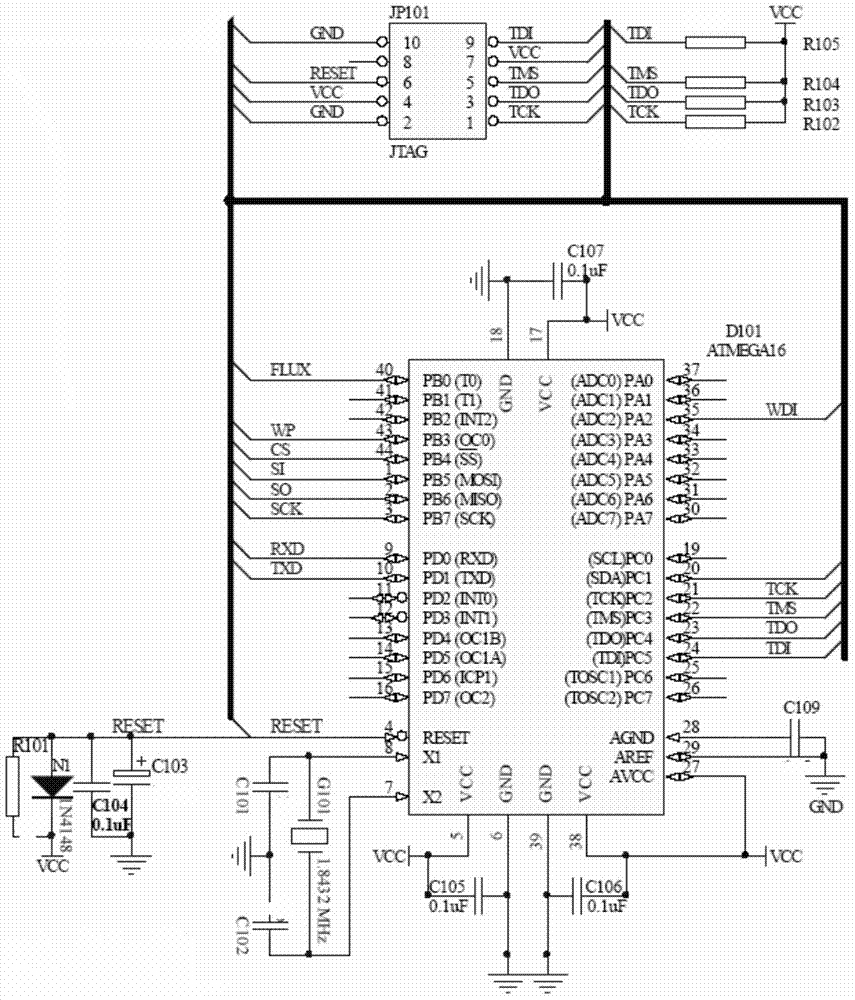

[0016] exist figure 1 Among them, the intelligent electromagnetic induction flow sensor includes a mechanical part, a signal conversion part and a digital part. The mechanical part includes impellers and guides that are assembled in the housing to generate electromagnetic induction signals. The signal conversion part and the digital part include a signal conversion circuit composed of a modulation amplifier circuit, a filter circuit and a detection and shaping circuit signal, and a digital circuit including a power supply module, a signal processing module, a data storage module and a communication module. The signal conversion circuit and digital circuit are made into a standard module and integrated in the flow sensor. The liquid flows through the flow sensor, drives the impeller to rotate throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com