Ultrasonic wave head wave phase reversal testing method for depth of shallow fracture in surface of concrete

A concrete surface, phase inversion technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problem of high accuracy of detection results, and achieve the effect of easy operation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

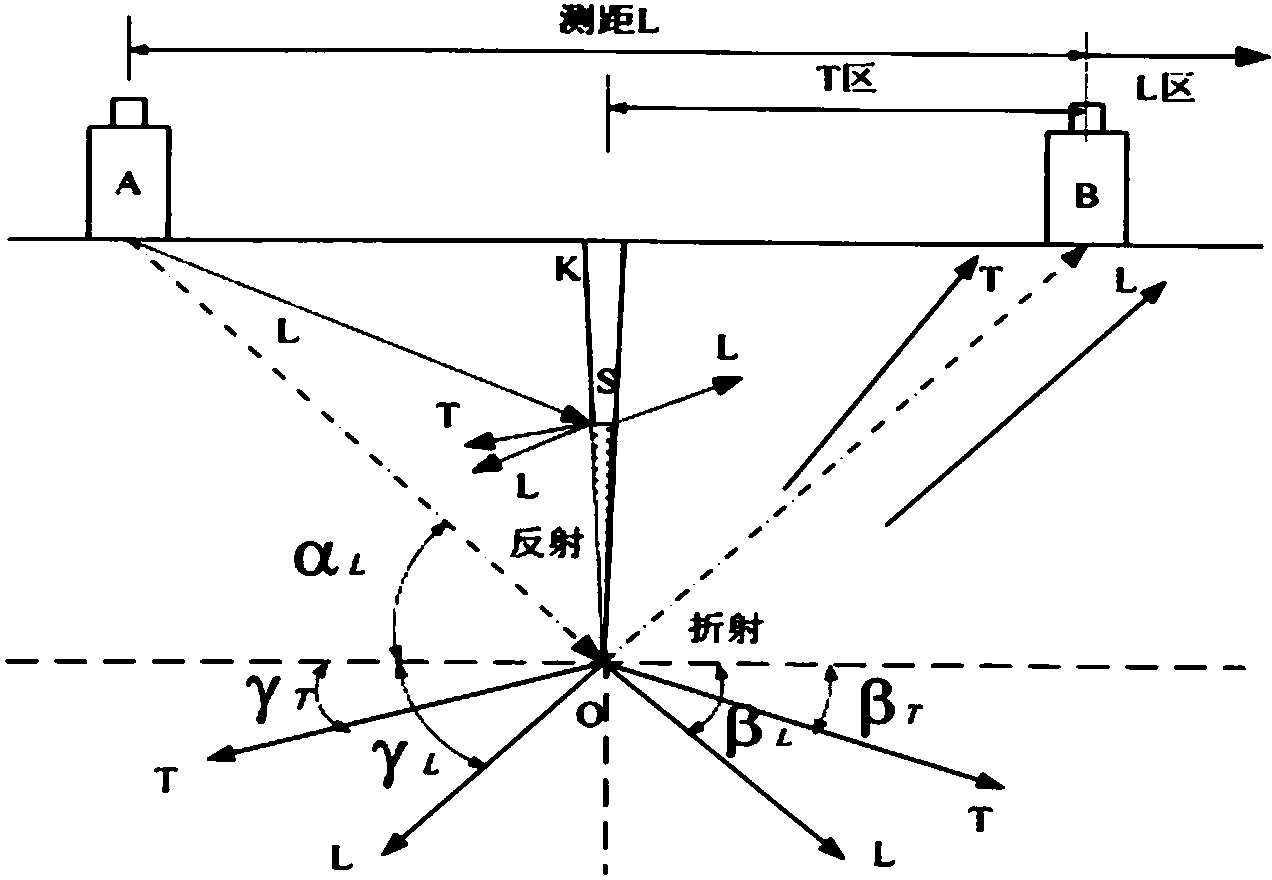

[0029] Test Method Mechanism

[0030] Known from physics:

[0031] 1) The interface of media with different sound velocities may undergo wave mode conversion during the process of reflection and refraction. Mode conversion occurs only at oblique incidence.

[0032] 2) At the interface between solid and gas, the waveform conversion only occurs during the reflection process; the interface between solid and solid will undergo waveform conversion during the reflection and refraction process. At the interface between solid and liquid, there are only longitudinal waves among the refracted waves, and because the liquid medium has no shear elasticity, it cannot retransmit transverse waves.

[0033] When the transducers are placed on both sides of the crack surface, such as figure 1 As shown, because concrete detection usually uses low-frequency (50kHz) ultrasonic waves, which are characterized by long wavelengths and poor directivity. When the transmitting transducer A is placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com