Ultra-thin led light engine

A light engine and ultra-thin technology, applied in the field of integrated LED lighting devices, can solve the problems of miniaturization and other problems, and achieve the effects of heat dissipation, simple use, and improved heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings.

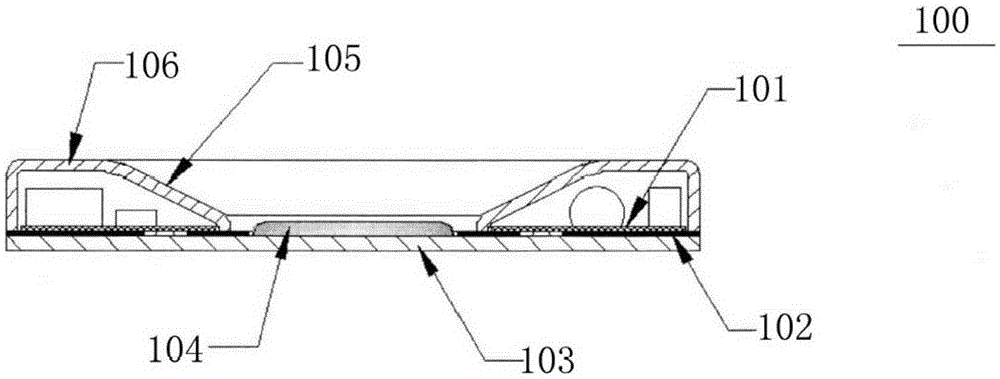

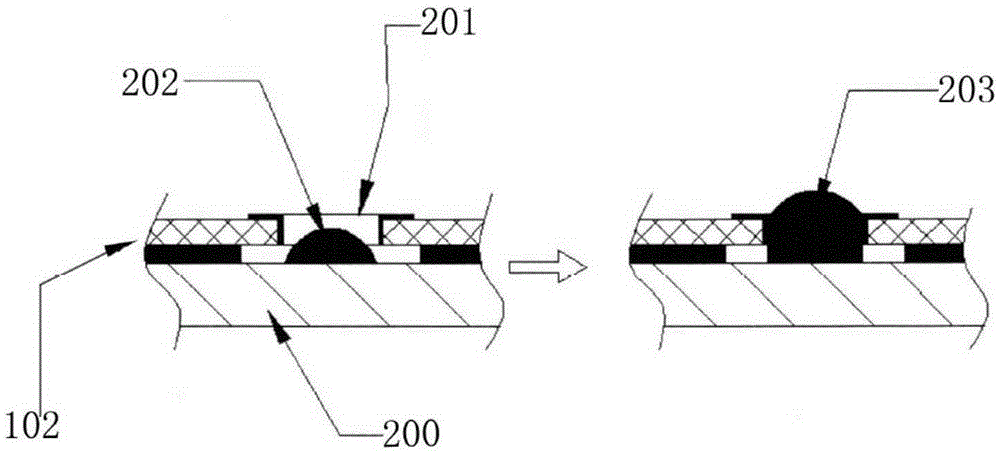

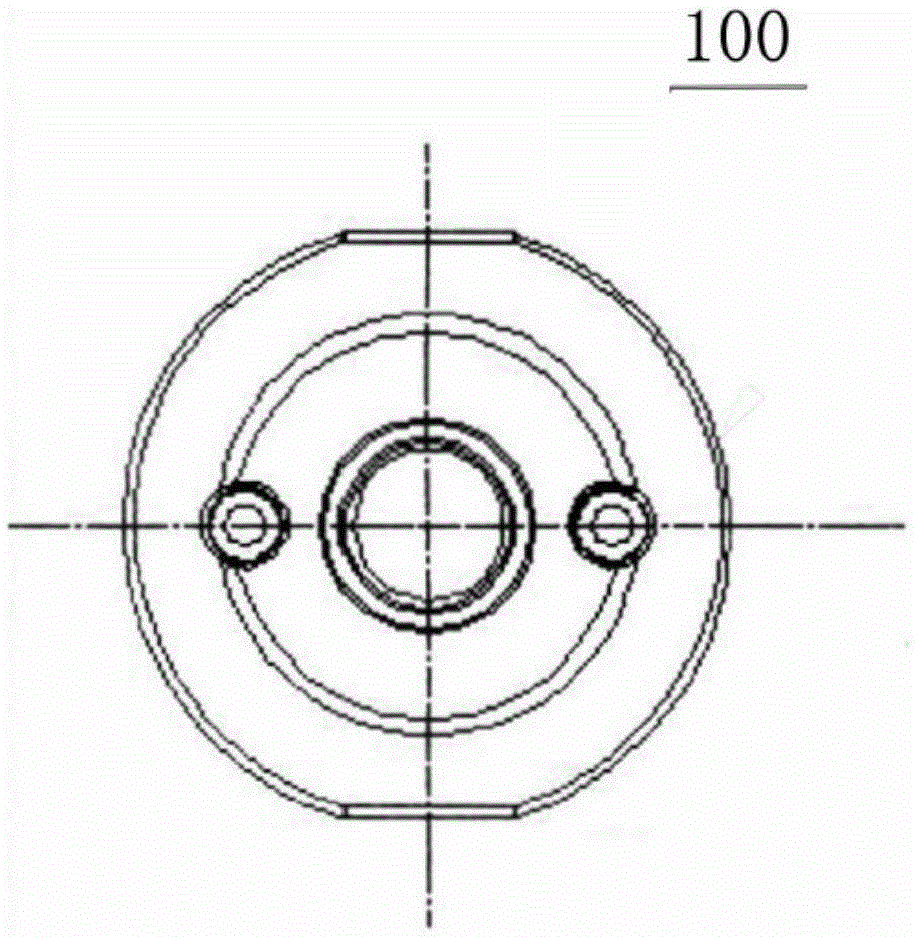

[0053] figure 1 An ultra-thin LED light engine 100 is shown, which includes a protective cover 106 , a driving circuit board 101 , an aluminum substrate 103 and at least one LED module 104 . As shown in the figure, the ultra-thin LED light engine 100 is facing upwards with a light emitting surface. Below is the aluminum substrate. The protective cover 106 is used to cover and protect the driving circuit board 101 to prevent external damage to the driving circuit board and to protect it from moisture and the like. The aluminum substrate 103 and at least one LED module 104 are closely attached to each other through the double-sided high-adhesive heat conduction sheet 102 .

[0054] The first surface of the aluminum substrate is covered by a double-sided high-adhesive heat conduction sheet 102 , and the driving circuit board 101 is fixed by means of the double-sided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com