Method for improving emissivity of paint film

A technology of emissivity and paint film, applied in sputtering plating, vacuum evaporation plating, ion implantation plating, etc., can solve the problems of high emissivity limitation and achieve high emissivity and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

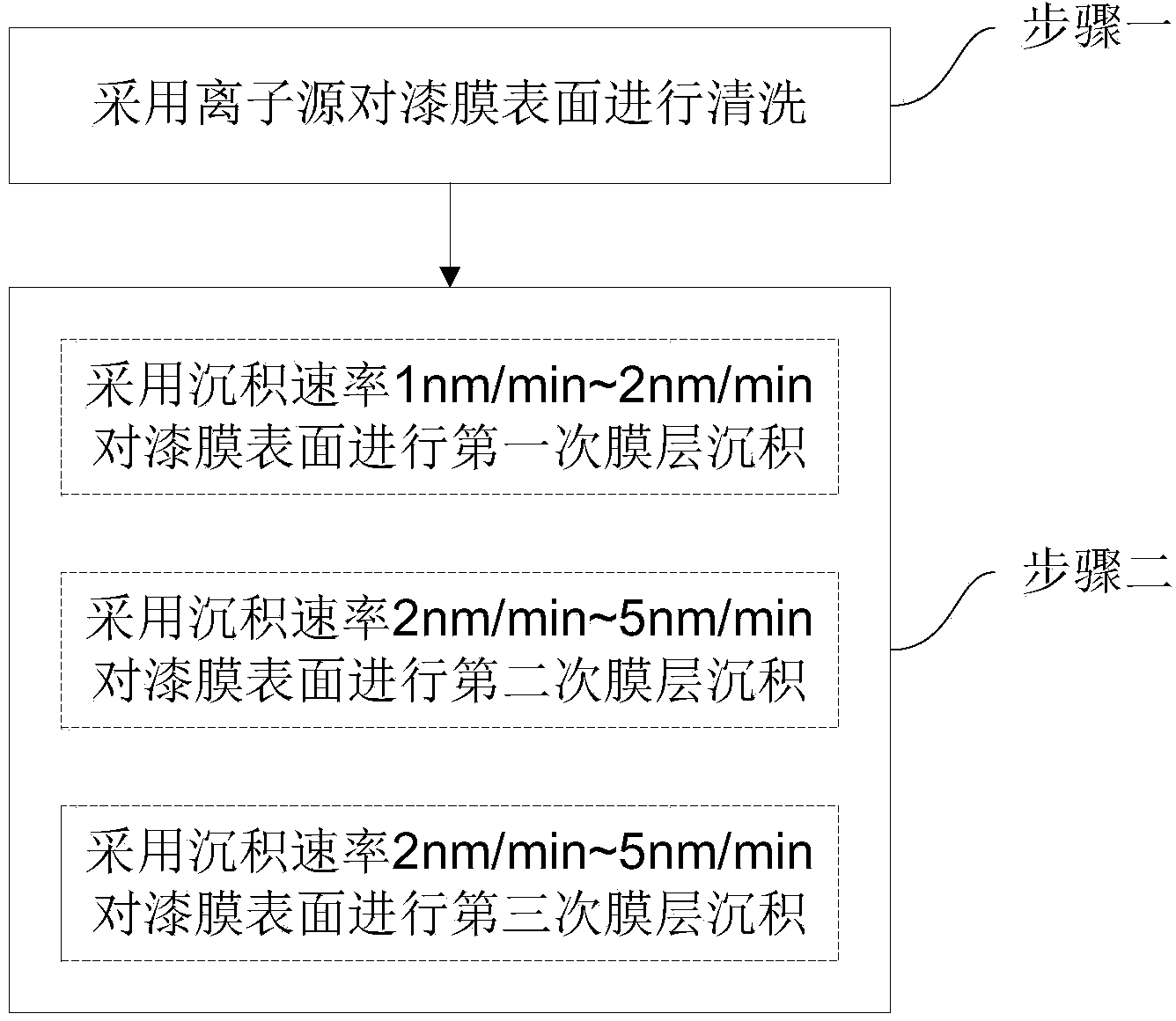

Method used

Image

Examples

example 1

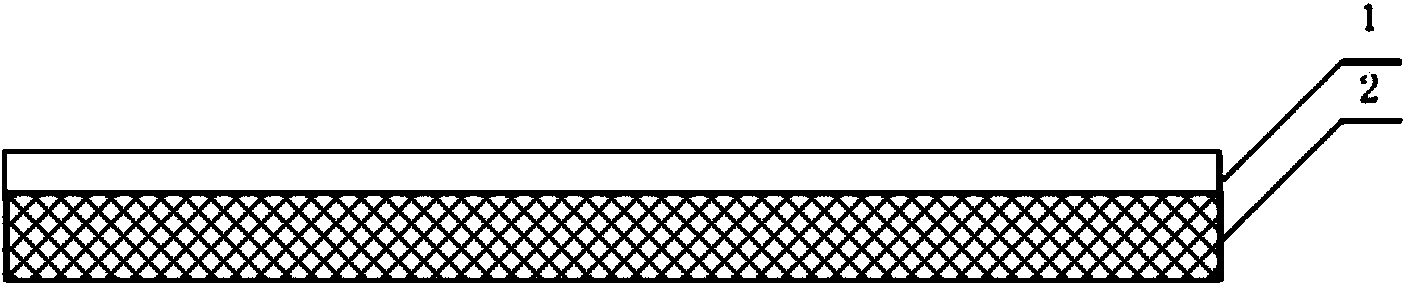

[0029] According to the high emissivity paint film prepared by the above method, by such as figure 2 As shown, the paint film layer and the transparent emissivity adjustment film, wherein the material of the paint film layer is a silicone resin-based coating, the transparent emissivity adjustment film is a silicon dioxide film, and the thickness of the transparent emissivity adjustment film is 200nm.

example 2

[0031] The high-emissivity paint film prepared according to the above method is composed of a paint film layer and a transparent emissivity adjustment film, wherein the material of the paint film layer is a silicone resin-based coating, the transparent emissivity adjustment film is a silicon dioxide film, and the transparent emissivity adjustment The thickness of the film was 300 nm.

example 3

[0033] The high-emissivity paint film prepared according to the above method is composed of a paint film layer and a transparent emissivity adjustment film, wherein the material of the paint film layer is a silicone resin-based coating, the transparent emissivity adjustment film is a silicon dioxide film, and the transparent emissivity adjustment The thickness of the film was 300 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com