A device for vacuum distillation and purification of metals

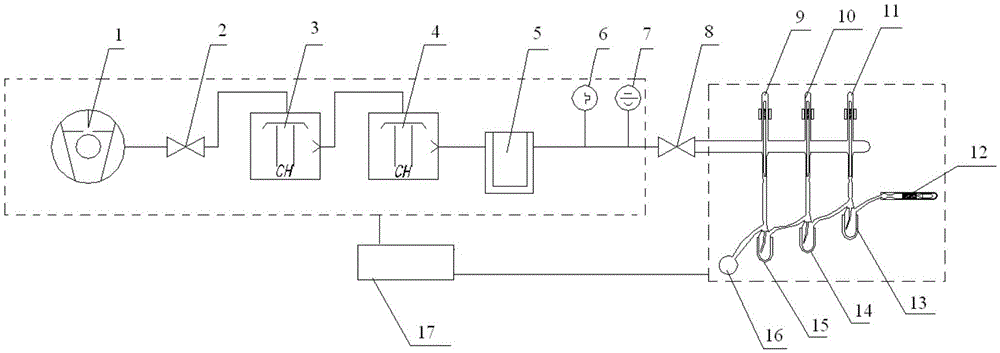

A metal purification and vacuum technology, which is applied in the field of vacuum distillation and purification of metals, can solve the problems of long distillation time, low distillation efficiency, and high cost, and achieve the effects of improving distillation efficiency, reducing costs, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

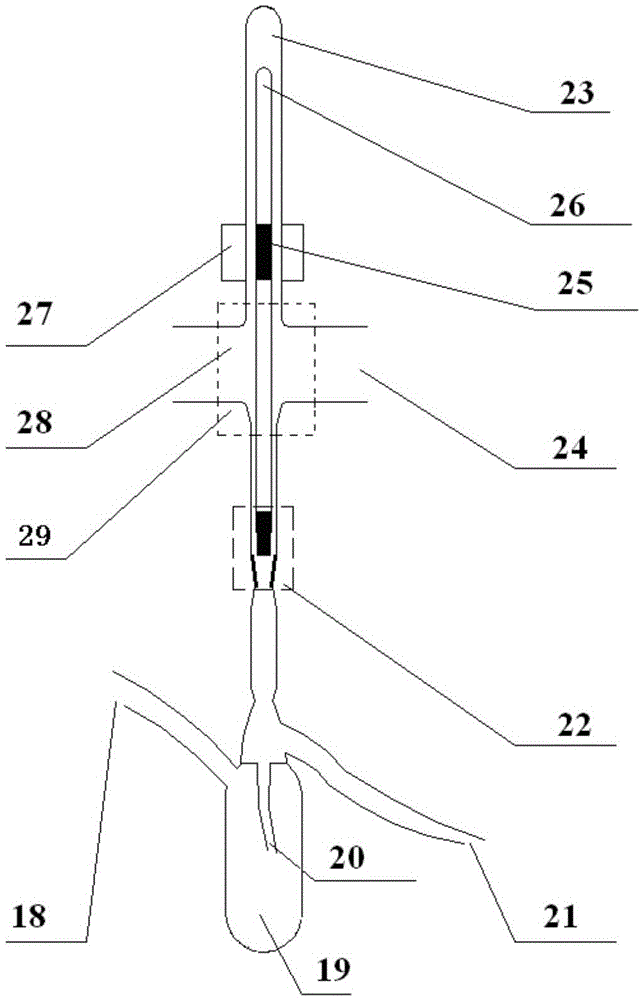

[0032] Embodiment: Implement three-stage directional distillation to cesium metal

[0033] Such as figure 2 As shown, the flow control directional still is made up of still container 19, distillation tube 23, control rod 26, magnetic substance 25 and magnet 27;

[0034] Wherein, the upper end of the distillation tube 23 is sealed, and the lower end of the distillation tube 23 is connected with the still container 19, and a flow control port 20 and a still outlet 21 are arranged at the bottom of the distillation tube 23, wherein the flow control port 20 is located inside the still container 19, and the still The outlet 21 is located outside the still vessel 19; the still inlet 18 is provided on the top of the still vessel 19;

[0035] The control rod 26 is built into the distillation tube 23, and the lower end of the control rod 26 is provided with an outer grinding port, and an inner grinding port is provided at the position where the inner wall of the distillation tube 23 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com