Production method of lysine

A production method and lysine technology, which are applied in the production field of lysine, can solve the problem of low lysine production capacity, etc., and achieve the effects of improving the lysine content at the end point, improving economic benefits and improving production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

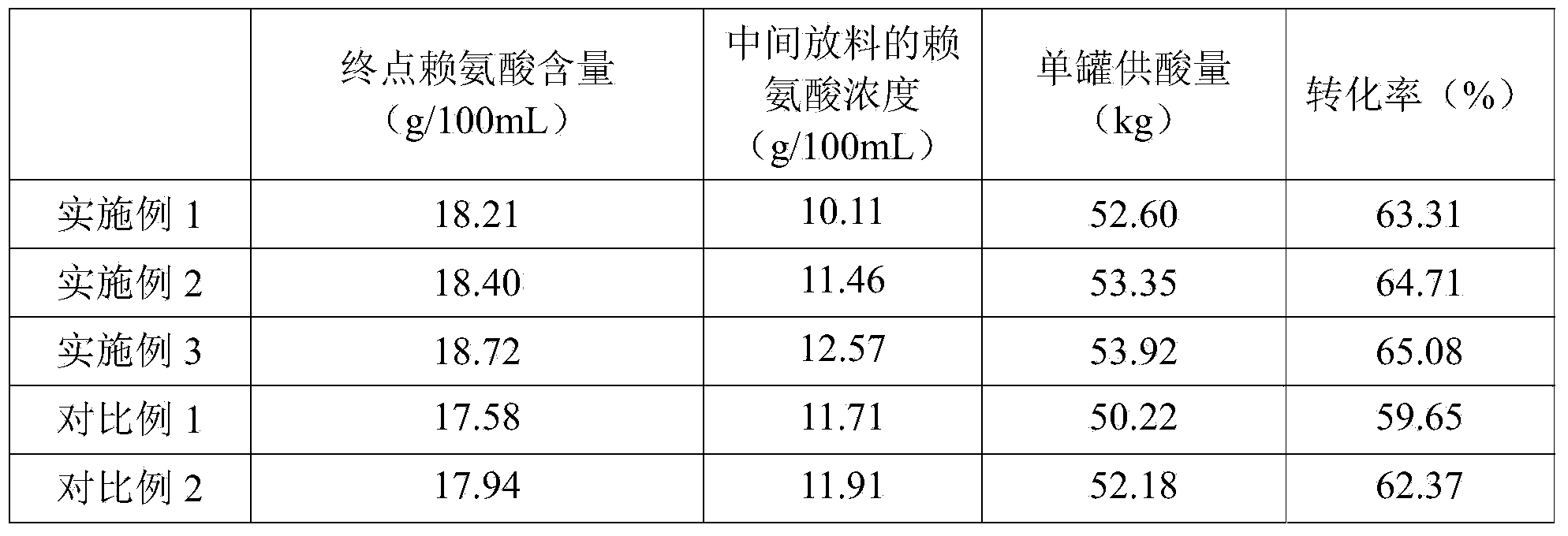

Embodiment 1

[0071] This example is used to illustrate the production method of lysine provided by the present invention.

[0072] (1) preparation of seed tank culture medium, concrete composition is: relative to every liter of culture medium, the consumption of getting the liquefied supernatant of starchy raw materials is 35 grams, the consumption of corn steep liquor (35% by weight) is 80 grams, phosphoric acid The consumption of dipotassium hydrogen is 1.0 grams, the consumption of magnesium sulfate is 0.5 grams, the consumption of ammonium sulfate is 10 grams, the consumption of threonine is 0.2 grams, the consumption of methionine is 0.2 grams, the consumption of glutamic acid is 0.2 grams, biological The consumption of vitamin B1 is 0.01 mg, the consumption of nicotinamide is 0.1 mg, and the consumption of vitamin B1 is 0.2 mg. Heat the medium to 121°C for disinfection, maintain it for 20 minutes, then cool down to 37°C and keep it constant. Turn on the stirring, adjust the tank pre...

Embodiment 2

[0077] This example is used to illustrate the production method of lysine provided by the present invention.

[0078] The formulation of the medium for the seed tank, the culture method for the mature seed liquid of the seed tank, and the formulation of the medium for the fermenter are all the same as in Example 1.

[0079] The medium volume in the fermentor was 40% of the fermentor volume. The mature seed liquid is inserted into the culture medium of the fermenter for fermentation and cultivation, and the inoculum amount of the seed liquid is 12% by volume based on the inoculated fermentation medium. After the inoculation, the starchy raw material liquefied clear liquid and ammonium sulfate were fed continuously, and the amount of the starchy raw material liquefied clear liquid obtained by feeding was added so that the concentration of reducing sugar in the fermentation broth was controlled at 5-7 grams per liter. Add the amount of ammonium sulfate to control the concentrati...

Embodiment 3

[0082] This example is used to illustrate the production method of lysine provided by the present invention.

[0083] The formulation of the medium for the seed tank, the culture method for the mature seed liquid of the seed tank, and the formulation of the medium for the fermenter are all the same as in Example 1.

[0084]The medium volume in the fermentor was 60% of the fermentor volume. The mature seed liquid is inserted into the culture medium of the fermenter for fermentation and cultivation, and the inoculum amount of the seed liquid is 18% by volume based on the inoculated fermentation medium. After the inoculation, the starchy raw material liquefied clear liquid and ammonium sulfate were fed continuously, and the amount of the starchy raw material liquefied clear liquid obtained by feeding was added so that the concentration of reducing sugar in the fermentation broth was controlled at 8-10 grams per liter. The amount of ammonium sulfate added is to control the concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com