Composite material carriage and manufacturing method thereof

A composite material and manufacturing method technology, which is applied in the application field of composite materials, can solve the problems of large overall weight and large power consumption, and achieve the effects of reduced process procedures, good quality, and good molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

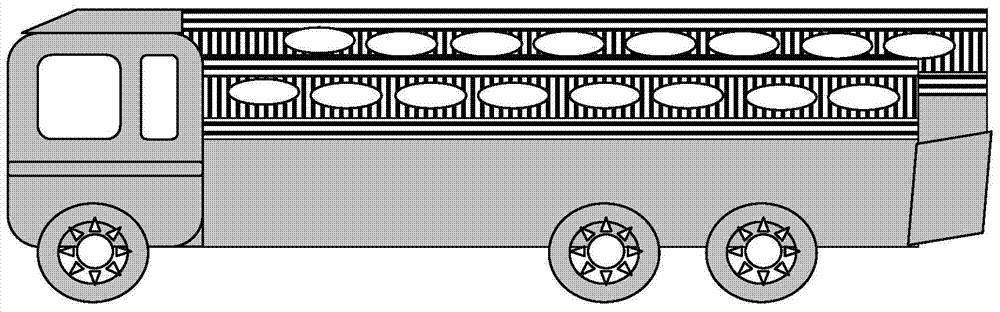

Image

Examples

Embodiment 1

[0014] The weight ratio of the carbon fiber is 60%, the weight ratio of the resin is 35%, the weight ratio of the zeolite powder is 1.5%, and the weight ratio of the rare earth is 3.5%.

Embodiment 2

[0016] The weight ratio of the carbon fiber is 62%, the weight ratio of the resin is 33%, the weight ratio of the zeolite powder is 1.5%, and the weight ratio of the rare earth is 3.5%.

Embodiment 3

[0018] The present invention also provides a method for manufacturing the above-mentioned composite material carriage. After the carbon fiber is woven, the resin is uniformly coated on the carbon fiber fabric, and then the carbon fiber fabric is molded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com