Anti-friction polypropylene material and preparation method thereof

A friction-resistant polypropylene and polypropylene technology, which is applied in the field of polypropylene composite material preparation, can solve the problems of limited application scope, high cost, influence on material appearance, etc., and achieves improved heat resistance, comprehensive performance balance, and good friction resistance. and rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

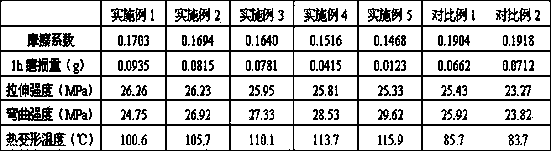

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] Below in conjunction with embodiment, the present invention is described in further detail:

[0026] In the composite material formulations of Examples and Comparative Examples, polypropylene is a copolymerized polypropylene produced by Beijing Yanshan Petrochemical Co., Ltd., with a product name of K8303. Described calcium carbonate whisker aspect ratio is 20~30, and diameter is 1~2 mu m. The aramid pulp is produced by Shanghai Lanbang Industrial Fiber Co., Ltd. The antioxidant used is 1010 produced by Beijing Huahui Chemical Factory, the trade name is CibaSCIrganox, and the chemical name is four [ β -(3,5-Di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester. The compatibilizer polypropylene grafted maleic anhydride is produced by Dongguan Yimao Plastics Co., Ltd., with the brand name PP-g-MAH.

[0027] Weigh the raw materials according to the ratio, put polypropylene, calcium carbonate whiskers, aramid pulp mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com