Pitch-based carbon fiber nonwoven felt insulation board and manufacturing method thereof

A pitch-based carbon fiber and non-woven felt technology is applied in the field of thermal insulation materials, which can solve the problems of high energy consumption and high thermal conductivity, and achieve the effects of good thermal insulation, good self-support and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

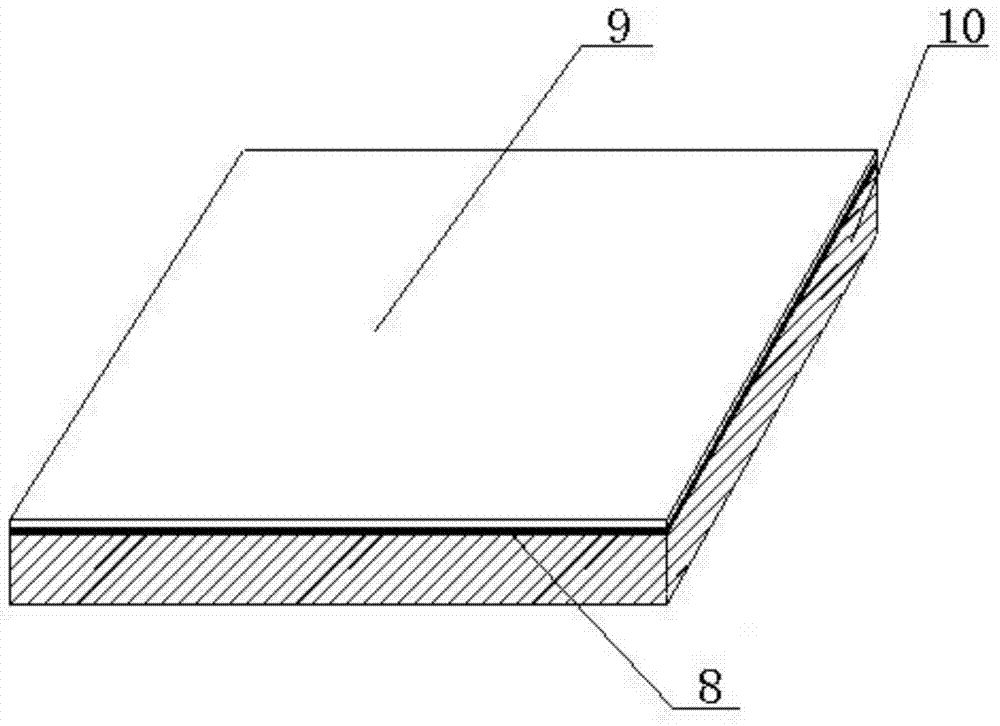

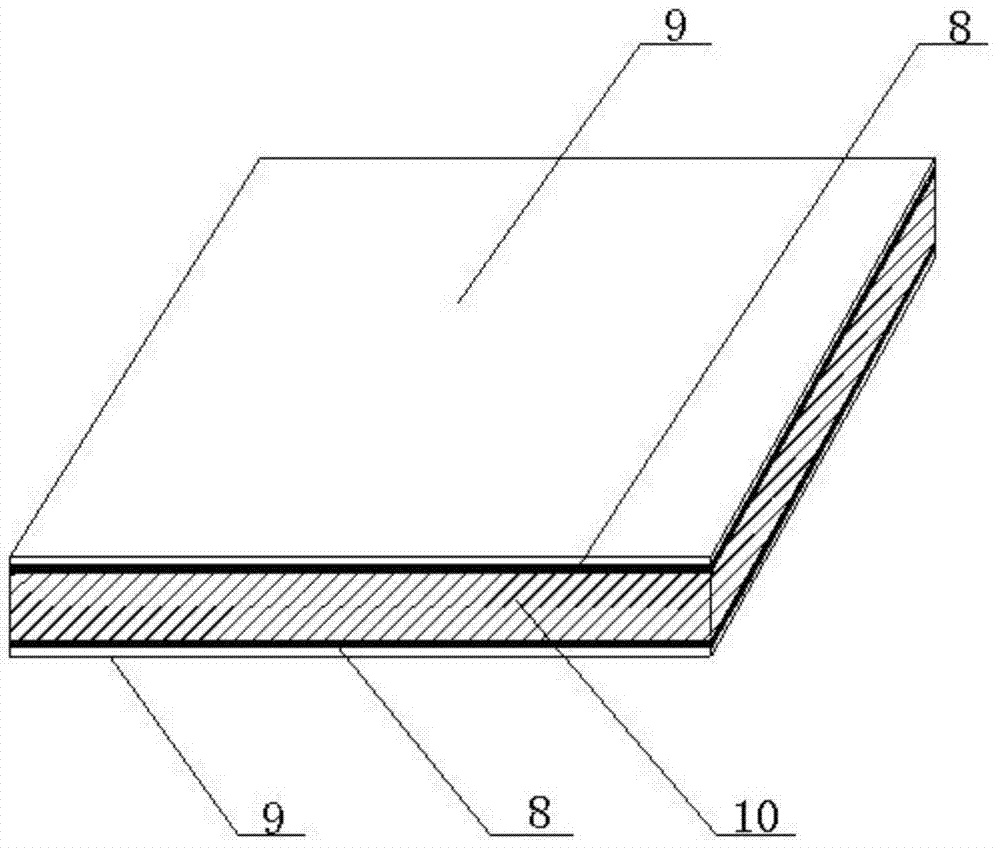

[0063] [Example 1] The manufacturing process of pitch carbon fiber non-woven felt insulation board is as follows:

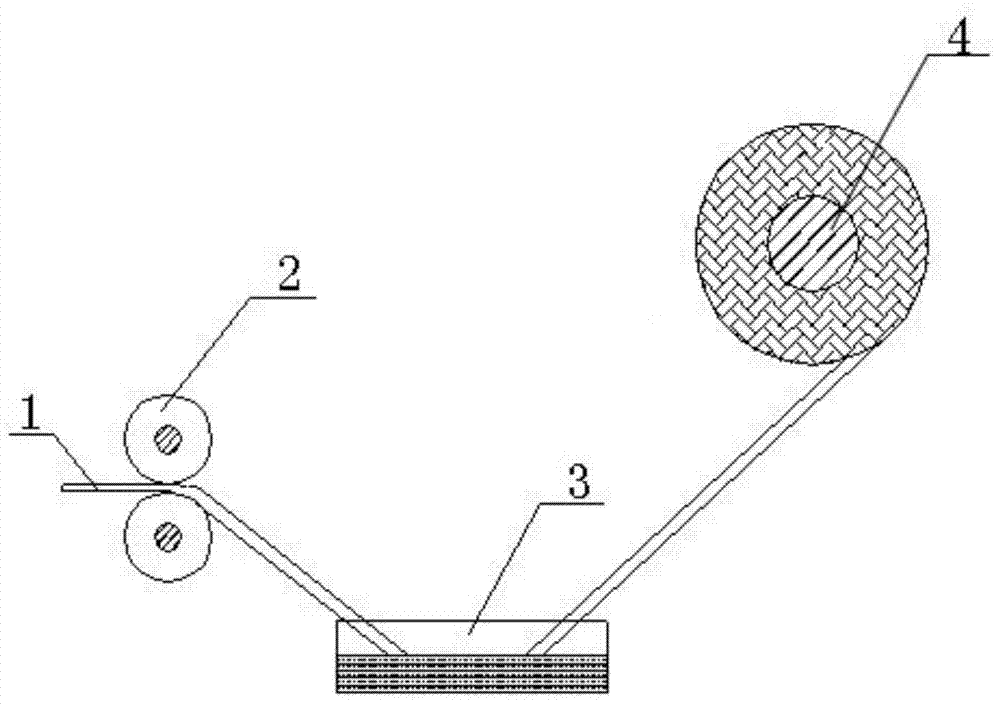

[0064] The pitch is spun to form a non-woven felt after being collected, then pre-oxidized, and then carbonized to obtain a pitch-based carbon fiber non-woven felt 1; under the rotation of the cylinder shaft 4, the pitch carbon fiber non-woven felt 1 is put into the organic Fully impregnated in the binder mixed solution pool 3 of binder+solvent, the organic binder is a phenolic resin, and the solvent is ethanol; the weight ratio of the binder mixed solution is phenolic resin:ethanol=40:60, and then The pitch-based carbon fiber non-woven felt 1 is squeezed out of the excess adhesive through the extrusion roller 2, and then the pitch-based carbon fiber non-woven felt 1 is cut according to the required size, and then laid flat on the lower mold 7 after stacking, and the molding is completed when the thickness reaches 70mm , and then the upper mold 5 is fixed on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com