Chemical waste leachate treatment agent and treatment method

A technology of landfill leachate and treatment method, applied in the field of chemical landfill leachate treatment agent and treatment, can solve the problems of inability to meet comprehensive sewage discharge standards, long treatment period, long treatment time, etc., and is conducive to large-scale treatment and treatment. The effect of short time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

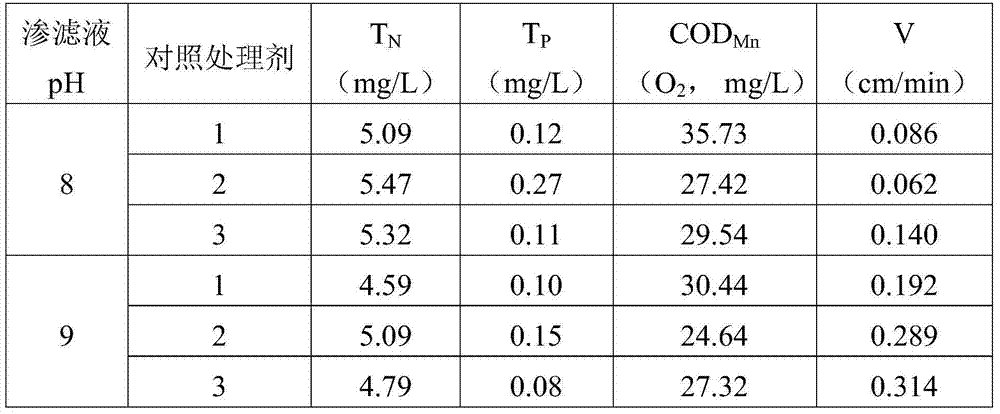

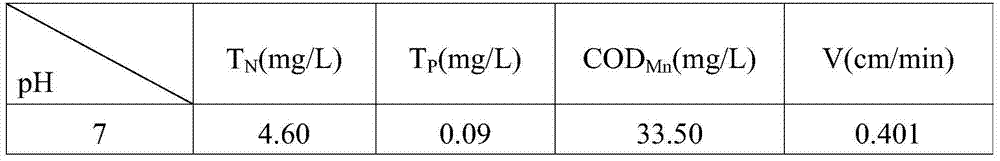

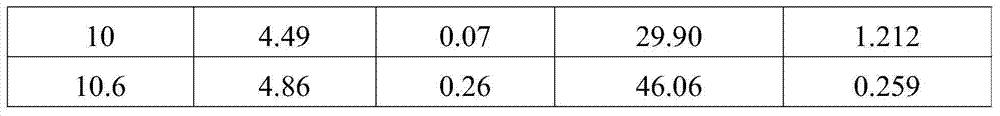

Embodiment 1

[0025] The chemical landfill leachate treatment agent of this embodiment is composed of alum (the first component) and polyacrylamide (the second component), and the weight ratio of alum and polyacrylamide is 15:3.

[0026] The chemical landfill leachate treatment method of the present embodiment comprises the following steps:

[0027] 1) Adjust the pH value of the chemical landfill leachate to 9 with a hydrochloric acid solution with a mass fraction of 37%.

[0028] 2) Take 10 L of the leachate with pH=9 above, add 15 g of the first component to it, and stir for about 2 minutes.

[0029] 3) Add 3g of the second component to the leachate obtained in the above step 2), and stir until flocs appear (about 2-3min), and the sedimentation velocity (V) of the flocs is about 6.5cm / min. The substance is basically completely precipitated, and after the precipitate is separated, the treatment solution is obtained.

[0030] Use alkaline potassium persulfate oxidation-ultraviolet spectro...

Embodiment 2

[0033] The chemical landfill leachate treatment agent of this embodiment is composed of alum (the first component) and polyacrylamide (the second component), and the weight ratio of alum and polyacrylamide is 15:1.

[0034] The chemical landfill leachate treatment method of the present embodiment comprises the following steps:

[0035] 1) Adjust the pH value of the chemical landfill leachate to 8 with a hydrochloric acid solution with a mass fraction of 37%.

[0036] 2) Take 100 L of the leachate with pH=8 above, add 150 g of the first component into it, and stir for about 3 minutes.

[0037] 3) Add 10g of the second component to the leachate obtained in the above step 2), and stir until flocs appear (about 2-3min), and the sedimentation velocity (V) of the flocs is about 2.026cm / min. The substance is basically completely precipitated, and after the precipitation is separated, a treatment solution is obtained; T in the treatment solution N 3.09mg / L, T P 0.05mg / L, COD Mn is...

Embodiment 3

[0040] The chemical landfill leachate treatment agent of this embodiment is composed of alum (the first component) and polyacrylamide (the second component), and the weight ratio of alum and polyacrylamide is 10:5.

[0041] The chemical landfill leachate treatment method of the present embodiment comprises the following steps:

[0042] 1) Adjust the pH value of the chemical landfill leachate to 9.5 with a hydrochloric acid solution with a mass fraction of 37%.

[0043] 2) Take 1000 L of the above leachate with pH=9.5, add 1000 g of the first component into it, and stir for about 4 minutes.

[0044] 3) Add 500g of the second component to the leachate obtained in the above step 2), stir until flocs appear (about 2-3min), and the sedimentation velocity (V) of the flocs is about 6.4cm / min. The substance is basically precipitated completely, and after the precipitation is separated, a treatment solution is obtained; T in the treatment solution N 4.12mg / L, T P 0.09mg / L, COD Mn i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com