Advertising inkjet supply and production method thereof

A production method and technology of consumables, applied in the field of inkjet advertising consumables and their production, can solve the problems of obvious snowflakes, low efficiency and rough surface of cold-laminated film products, so as to avoid re-lamination, save forestry resources, and have high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below according to the drawings and embodiments.

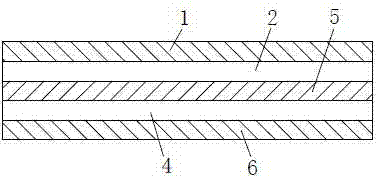

[0030] Such as image 3 As shown, an inkjet advertising consumable according to the embodiment of the present invention includes a transparent protective layer 1, an adhesive layer is provided under the protective layer 1, a silicone oil layer 5 is provided under the adhesive layer, and the silicone oil layer 5 A base layer 4 is provided below, and the base layer 4 is made of plastic material; an ink-absorbing coating 6 is provided below the base layer 4 .

[0031] The base layer 4 adopts PP synthetic paper or PEPA pearlescent paper or PET synthetic film. PP synthetic paper is generally made by mixing and pressing main raw materials such as polypropylene resin, polyethylene resin and natural stone powder; The abbreviation of ethylene terephthalate, the chemical formula is -OCH2-CH2OCOC6H4CO-, no more details.

[0032] The thickness specifications of the base l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com