Environment-friendly wood sawing device

A technology for sawing and lumber, applied in the field of environmental protection lumber cutting and sawing devices, can solve problems such as affecting the health of operators, and achieve the effect of reducing the amount of floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

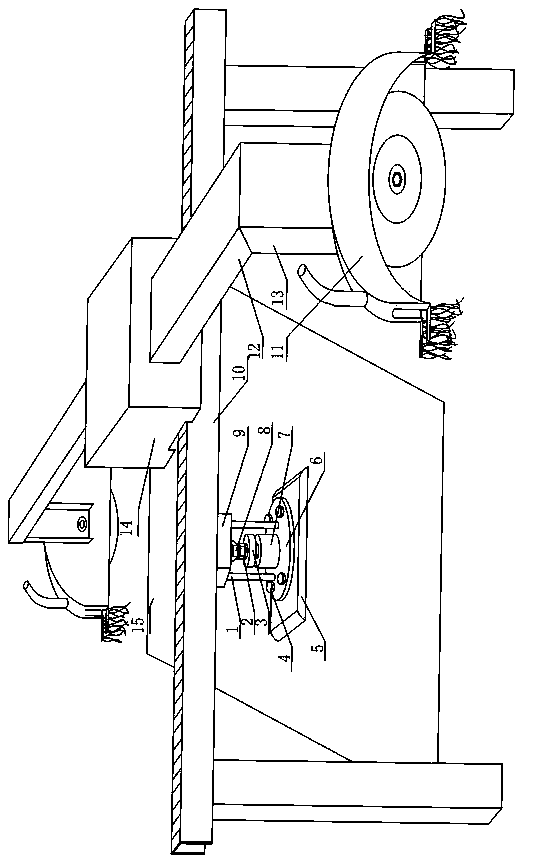

[0018] As shown in Figure 1, an environmentally friendly wood sawing device provided by the present invention includes a platform 15, a saw head 11 with a brush, a beam 10 with a concave-convex upper surface, a beam 12 of the saw head, and a vertical beam 13 of the saw head. And be fixed on described crossbeam 10 bottoms and be provided with screw mandrel 2, all have central hole and have the short spacer 3 of internal wire in the center hole and the timber pressing device of long spacer 7. The wood pressing device at the bottom of the beam 10 also includes a fixing seat 9, a locking nut 8, a plurality of reinforcing rods 1, a pressing block 6, a cushion 5 and a connecting bolt 4, and the upper end of the fixing seat 9 is fixed on the The lower part of the beam 10, the lower end is provided with a center hole and an annular chute matching with the screw mandrel 2, the upper part of the reinforcing rod 2 is placed in the annular chute, and the upper part of the screw mandrel 2 i...

Embodiment 2

[0020] This embodiment is further limited on the basis of Embodiment 1: as shown in Figure 1, an environmentally friendly wood sawing device provided by the present invention includes a screw rod 2, a locking nut 8, a short spacer 3 and a long spacer 7. Each thread form adopts M20*1 fine thread. Using this setting can improve the adjustment accuracy of the extension length of the briquette and the cushion, and the saw head can cut the wood raw materials in the compressed state. In the vibration generated by processing, the threaded joints are not easy to loosen.

Embodiment 3

[0022] This embodiment is further limited on the basis of Embodiments 1 and 2: as shown in Figure 1, an environmentally friendly wood sawing device provided by the present invention includes a reinforcing rod 1 set to a 20# steel round steel of Φ10, the price of this material Cheap, easy to purchase, and the flexural modulus meets the process requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com