Vitrification ultralow-temperature preservation method of flax seeds

A technology for vitrifying ultra-low temperature and flax seeds, which is applied in the fields of plant preservation, botanical equipment and methods, and applications, and achieves the effects of simple process, simple and convenient operation, and reliable stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Seed cryopreservation and thawing process

[0027] Take the flax "Zhongya No. 1" seeds harvested in the same year (provided by the flax breeding research group of the Institute of Hemp Research, Chinese Academy of Agricultural Sciences), dry them naturally, put the flax seeds with a water content of about 9% into the loading solution, load them for a certain period of time, The flax seeds are taken out and put into a centrifuge tube equipped with a glass protectant, and the centrifuge tube is placed in a gradient cooling box (produced by Nalgene Company of the United States, model 5100-0001) with 100% isopropanol, and then the gradient cooling box is put into- The 80°C low-temperature refrigerator was used for gradient cooling, and the isopropanol in the gradient cooling box was reused 4-5 times before being renewed. Lowered to a certain temperature, put into liquid nitrogen for storage. The flax seeds preserved in ultra-low temperature were thawed natura...

Embodiment 2

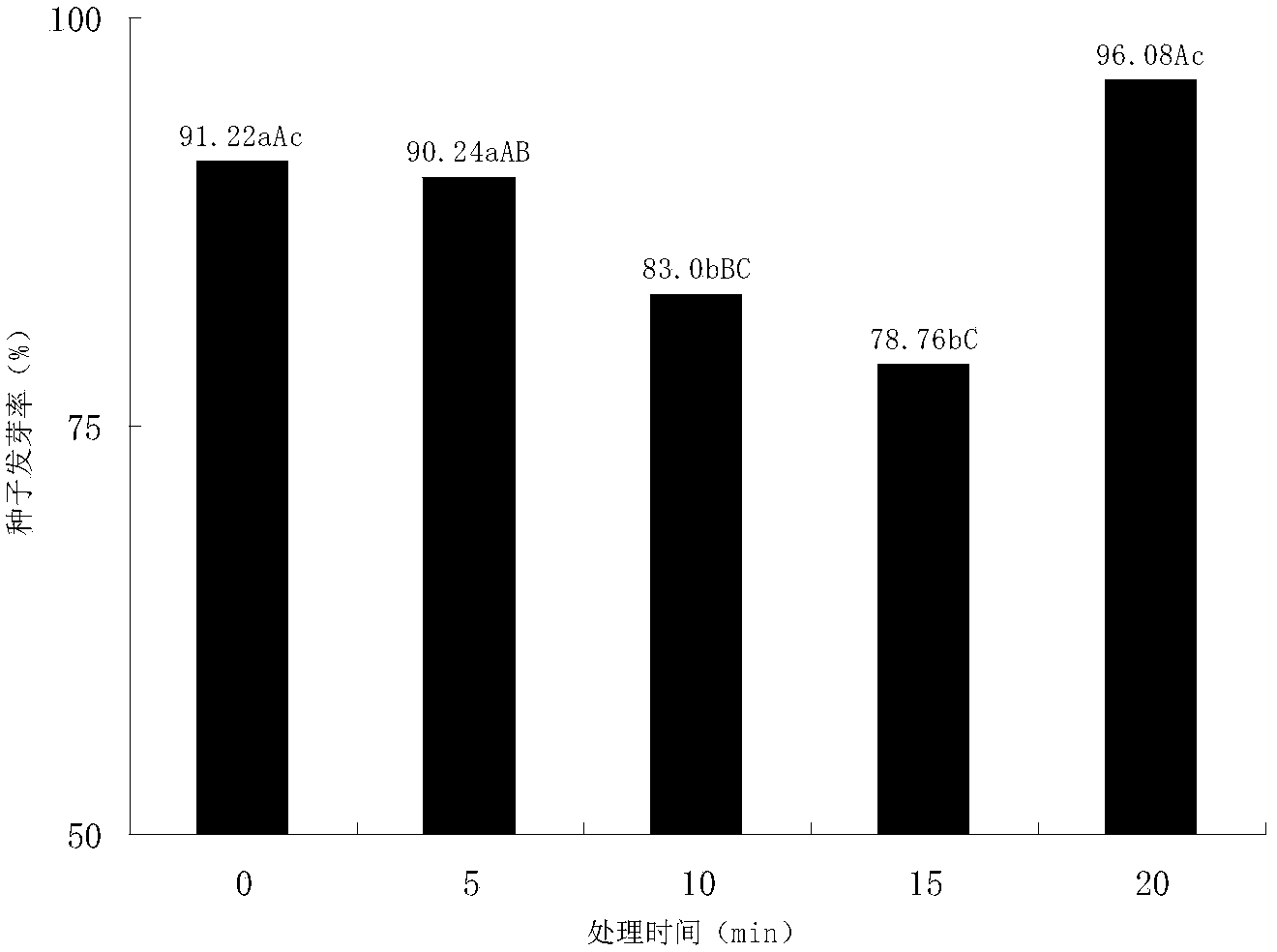

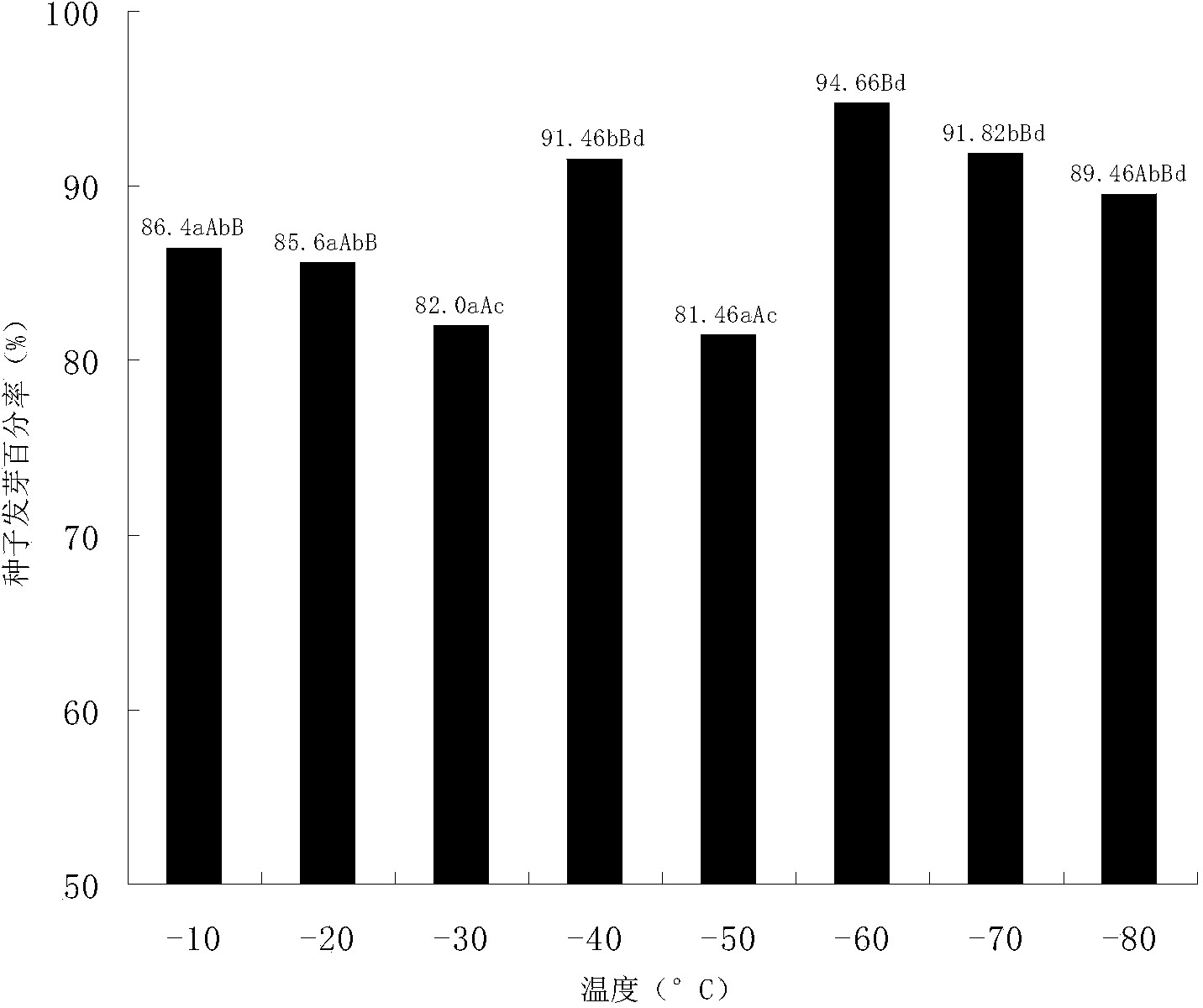

[0030] Embodiment 2: Determine the relationship between loading time (minutes), gradient drop to temperature and flax seed germination rate before dropping into liquid nitrogen

[0031] In this example, on the basis of Example 1, the loading time is designed to be 0min, 5min, 10min, 15min, and 20min, and the gradient drops to temperatures of -10°C, -20°C, -20°C, -30°C, -40°C, For -50°C, -60°C, -70°C, see Table 1 for details. A total of 40 groups of experiments were designed, and the number of flax seeds in each group was 50, repeated three times. After the flax seeds are stored at ultra-low temperature, they are evenly placed on moist filter paper (the filter paper is placed in a petri dish, and a thin layer of absorbent cotton is placed under the filter paper, and the absorbent cotton is moist), and then placed in an incubator at 25°C for 3 days. Remove the Petri dish and count the number of sprouts.

[0032] According to the results of germination rate, the effects of loadi...

Embodiment 3

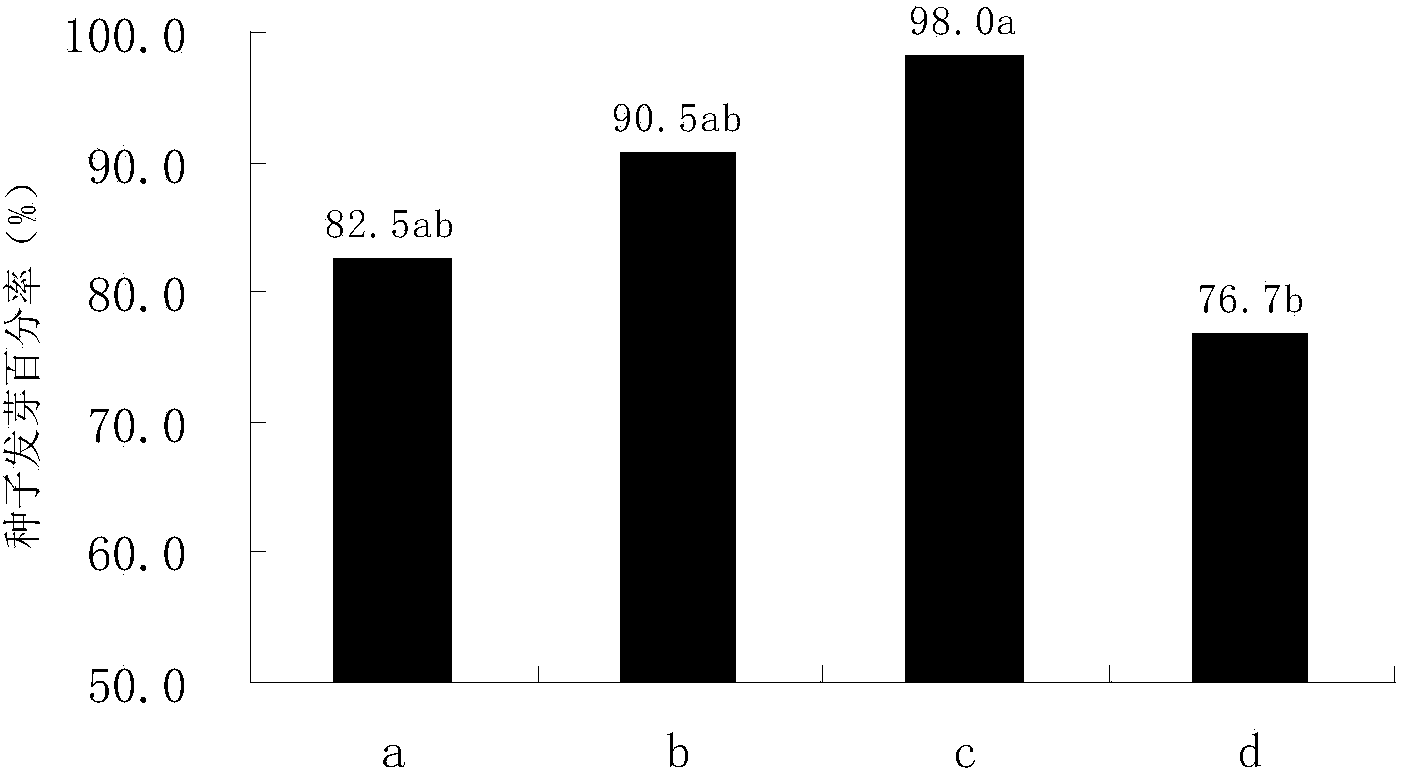

[0039] Embodiment 3: The relationship between the different preservation and treatment methods of flax seeds and the germination rate of flax seeds

[0040] In the present embodiment, different cryopreservation modes and processes designed on the basis of Example 1 are:

[0041] a. Fresh flax seeds are put into cryopreservation tubes without any treatment, and are directly stored in liquid nitrogen;

[0042] b The flax seeds are not loaded, directly add glass protective agent and put them in the cryopreservation tube, and store them in liquid nitrogen at ultra-low temperature;

[0043] c. Load the flax seeds for 20 minutes, add vitrification protective agent, gradually cool down to -40°C, and put them into liquid nitrogen for ultra-low temperature storage;

[0044] d Flaxseeds were loaded for 20 minutes, added vitrification protective agent, and put into liquid nitrogen for ultra-low temperature storage without gradient cooling.

[0045] In this embodiment, 50 plump flax see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com