Multipurpose wave absorbing film

A multi-purpose, film technology, applied in electrical components, magnetic field/electric field shielding, etc., can solve problems such as electromagnetic interference, human health hazards, abnormal work, etc., to achieve the effect of improving strength, improving utilization, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

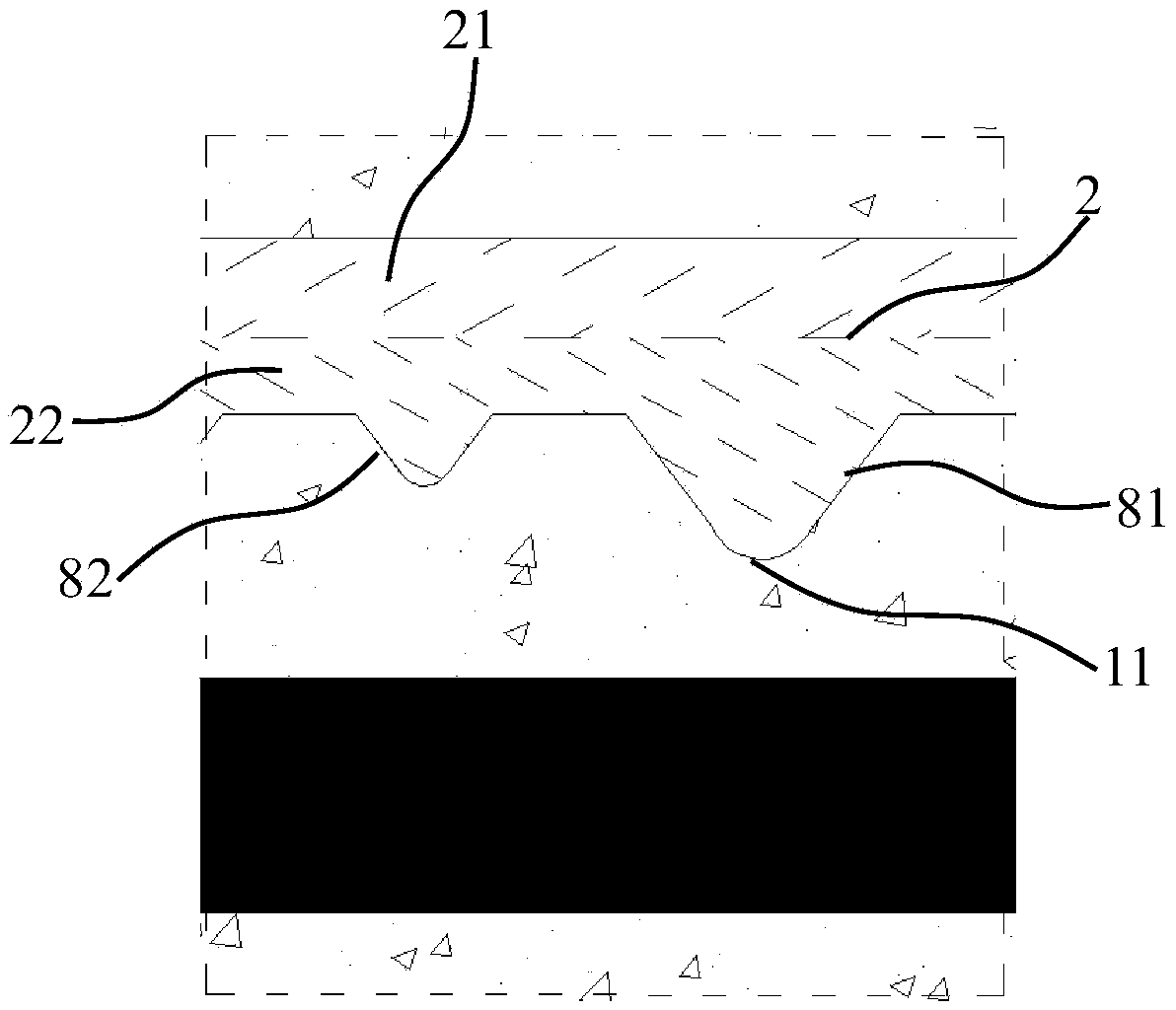

[0017] Example 1: A multi-purpose wave-absorbing film, including a PET insulating layer 1, a composite metal layer 2, a wave-absorbing layer 3, and a release material layer 4; a first glue is arranged between the PET insulating layer 1 and the composite metal layer 2 Adhesive layer 5, a second adhesive layer 6 is provided between the composite metal layer 2 and the wave-absorbing layer 3, the composite metal layer 2 is composed of a copper layer 21 and an aluminum foil layer 22, the composite metal layer 2 and The surface in contact with the absorbing layer 3 has several first prism protrusions 81 and first prism protrusions 82, the height of the first prism protrusions 81 is greater than the height of the second prism protrusions 82, the first The prism protrusions 81 and the second prism protrusions 82 are alternately arranged and there is a gap 9 between the respective bottoms of the adjacent first prism protrusions 81 and the second prism protrusions 82; the wave-absorbing ...

Embodiment 2

[0021] Example 2: A multi-purpose wave-absorbing film, including a PET insulating layer 1, a composite metal layer 2, a wave-absorbing layer 3, and a release material layer 4; a first glue is arranged between the PET insulating layer 1 and the composite metal layer 2 Adhesive layer 5, a second adhesive layer 6 is provided between the composite metal layer 2 and the wave-absorbing layer 3, the composite metal layer 2 is composed of a copper layer 21 and an aluminum foil layer 22, the composite metal layer 2 and The surface in contact with the absorbing layer 3 has several first prism protrusions 81 and first prism protrusions 82, the height of the first prism protrusions 81 is greater than the height of the second prism protrusions 82, the first The prism protrusions 81 and the second prism protrusions 82 are alternately arranged and there is a gap 9 between the respective bottoms of the adjacent first prism protrusions 81 and the second prism protrusions 82; the wave-absorbing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com