Circulating water system of cyclotron and water saving method of circulating water system

A technology of circulating water system and cyclotron, which is applied in magnetic resonance accelerators, accelerators, electrical components, etc., can solve the problem of wasting precious water resources, and achieve the elimination of water evaporation and loss, emission reduction, and reduction of backwash times. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

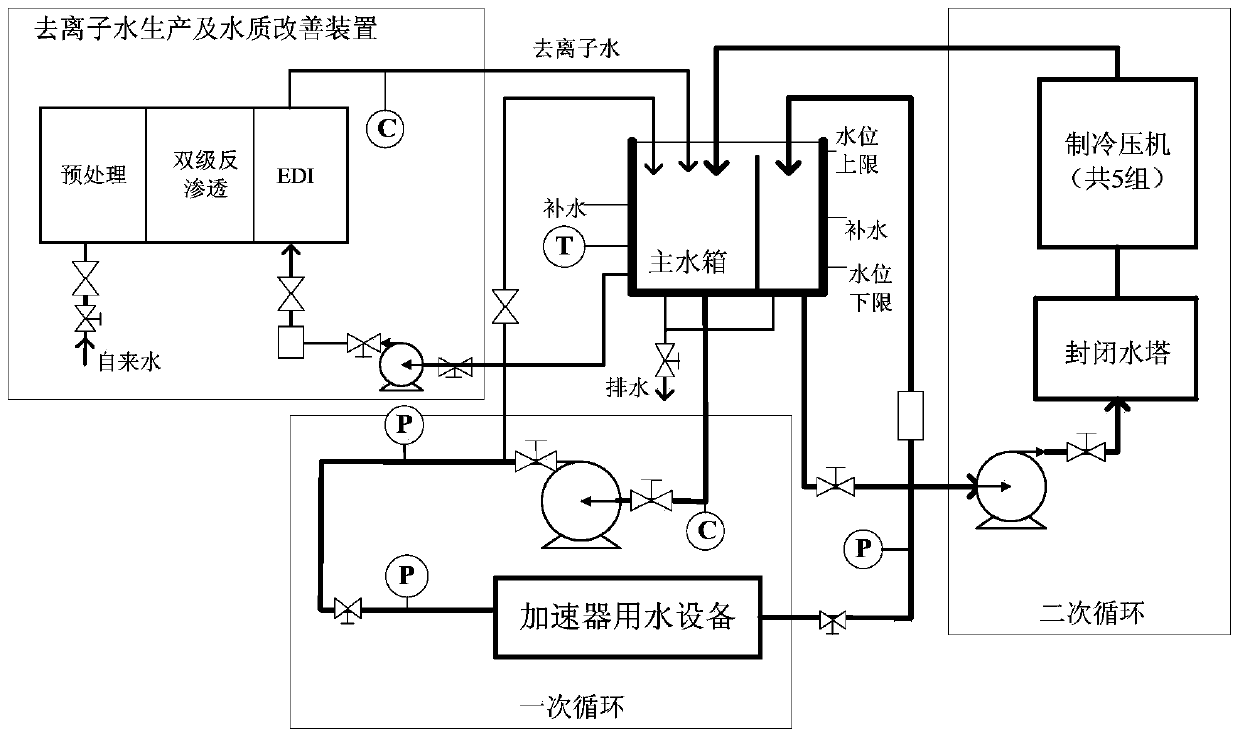

[0014] The structure of the 100MeV cyclotron is complex, and a complete circulating water cooling system needs to be established to meet its special requirements and lay the foundation for the long-term and stable operation of the accelerator equipment. This circulating water cooling system has a large cooling power (about 500kW), and the rated water flow of the system is 65T / h. In order to prevent scaling on the inner wall of the cooling water pipe and maintain the insulation performance of high-voltage equipment (≥40kV), the water quality is required to be better than 0.5μs / cm. Therefore, the circulating water cooling system must be equipped with an on-line deionization production and water quality improvement device. During normal operation, the continuous operation of this circulating water system consumes more than 8 tons of water per day. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com