Automotive lighting device

A technology for automotive lighting and transparent components, used in signaling devices, lighting and heating equipment, vehicle components, etc., to solve problems such as unfavorable glass condensation, low flow rate, and slow defogging speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The example embodiments are described in sufficient detail to enable one of ordinary skill in the art to embody and implement the systems and processes described herein. It is important to understand that embodiments may be provided in many alternative forms and should not be construed as limited to the examples set forth herein.

[0040] Therefore, although the embodiments may be modified in various ways and take various alternative forms, specific embodiments thereof are shown in the drawings and described in detail below as examples. There is no intention to be limited to the particular forms disclosed. On the contrary, it is intended to cover all modifications, equivalents and alternatives falling within the scope of the appended claims. Elements of the example embodiments are designated by the same reference numerals throughout the drawings and the detailed description where appropriate.

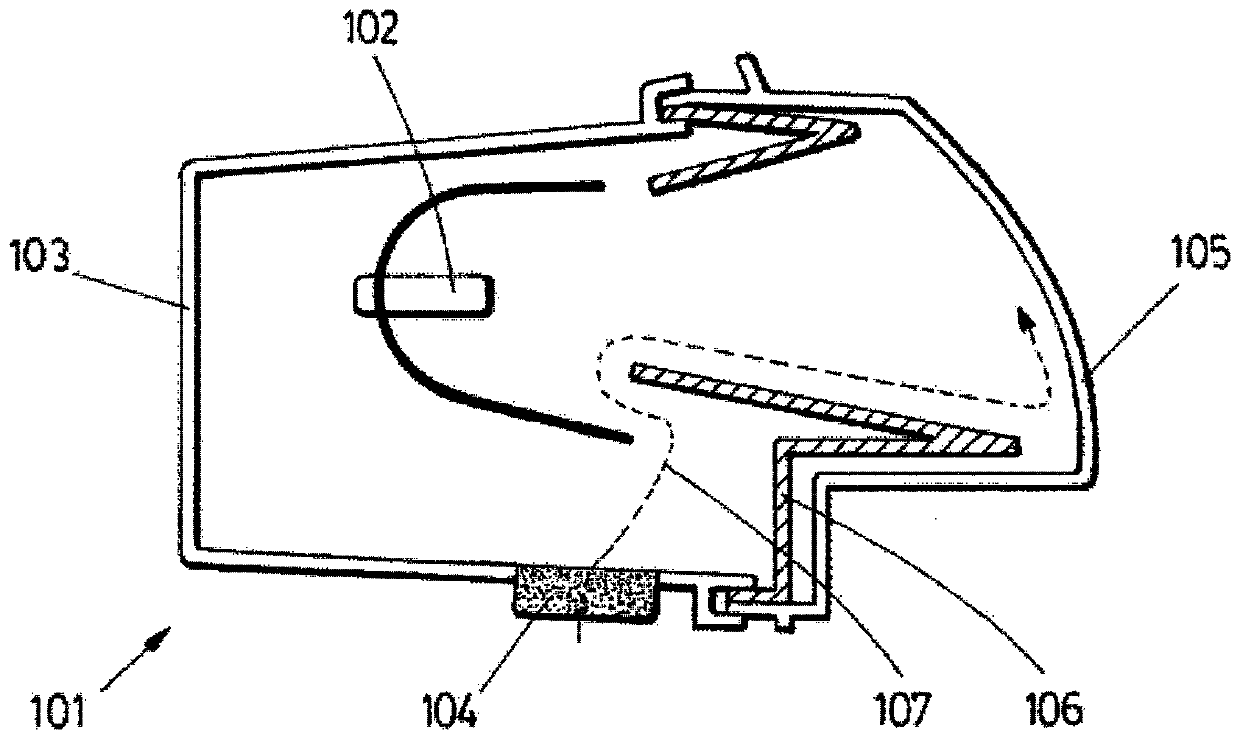

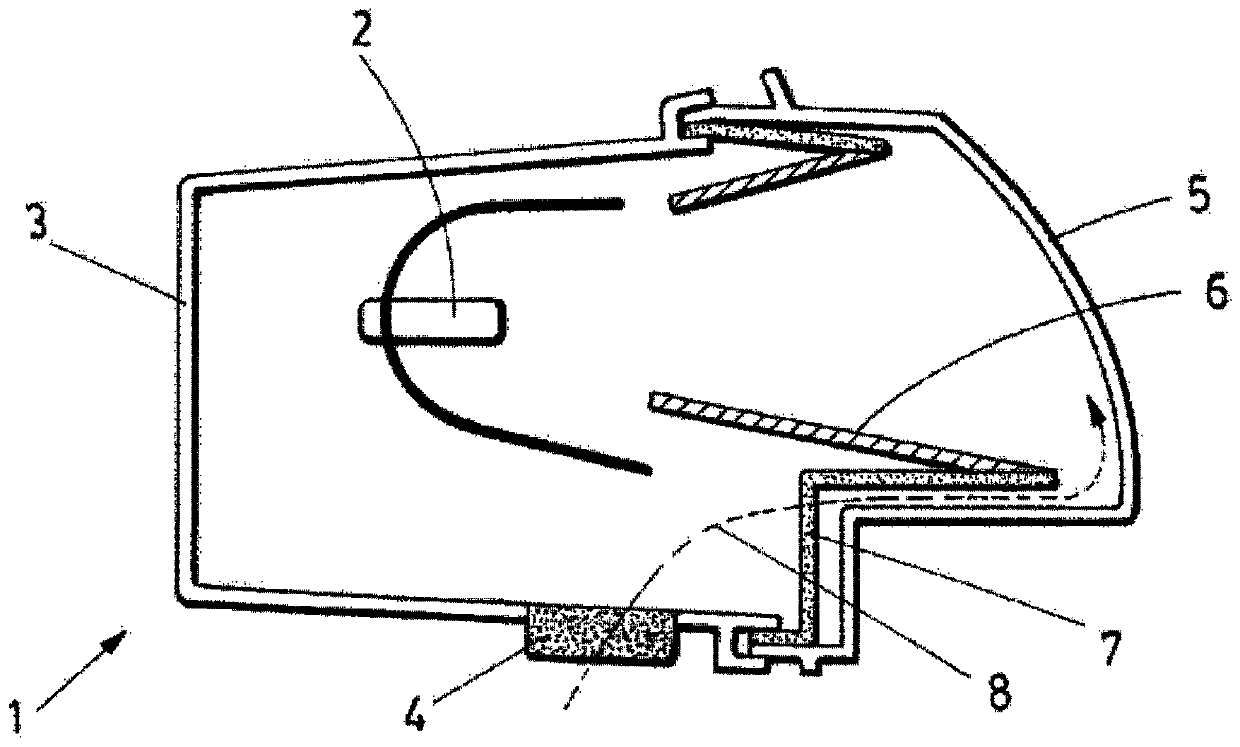

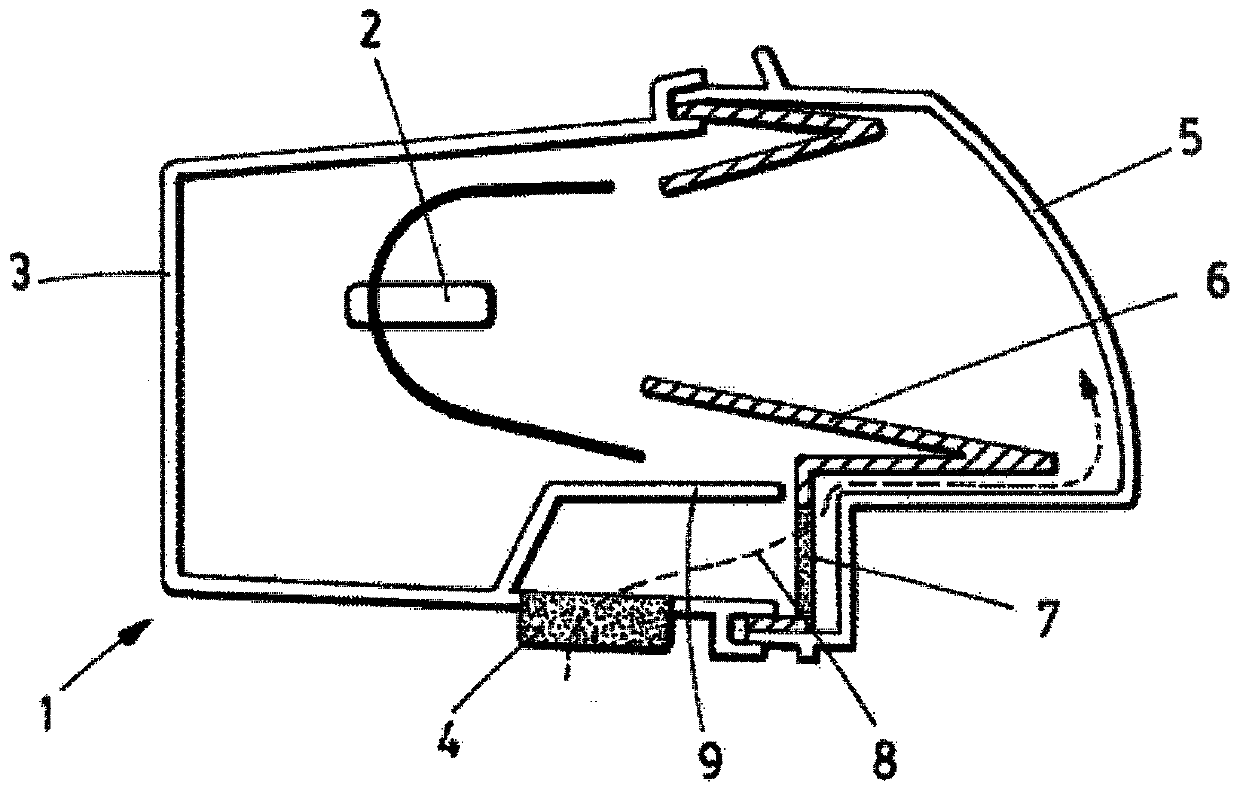

[0041] figure 1 A concept of an automotive lighting device 101 according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com