Three-phase symmetric printed winding

A technology of printing windings and phase windings, applied in the shape/style/structure of winding conductors, electric components, manufacturing motor generators, etc., to achieve the effects of good heat dissipation, high power-to-volume ratio, and small torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

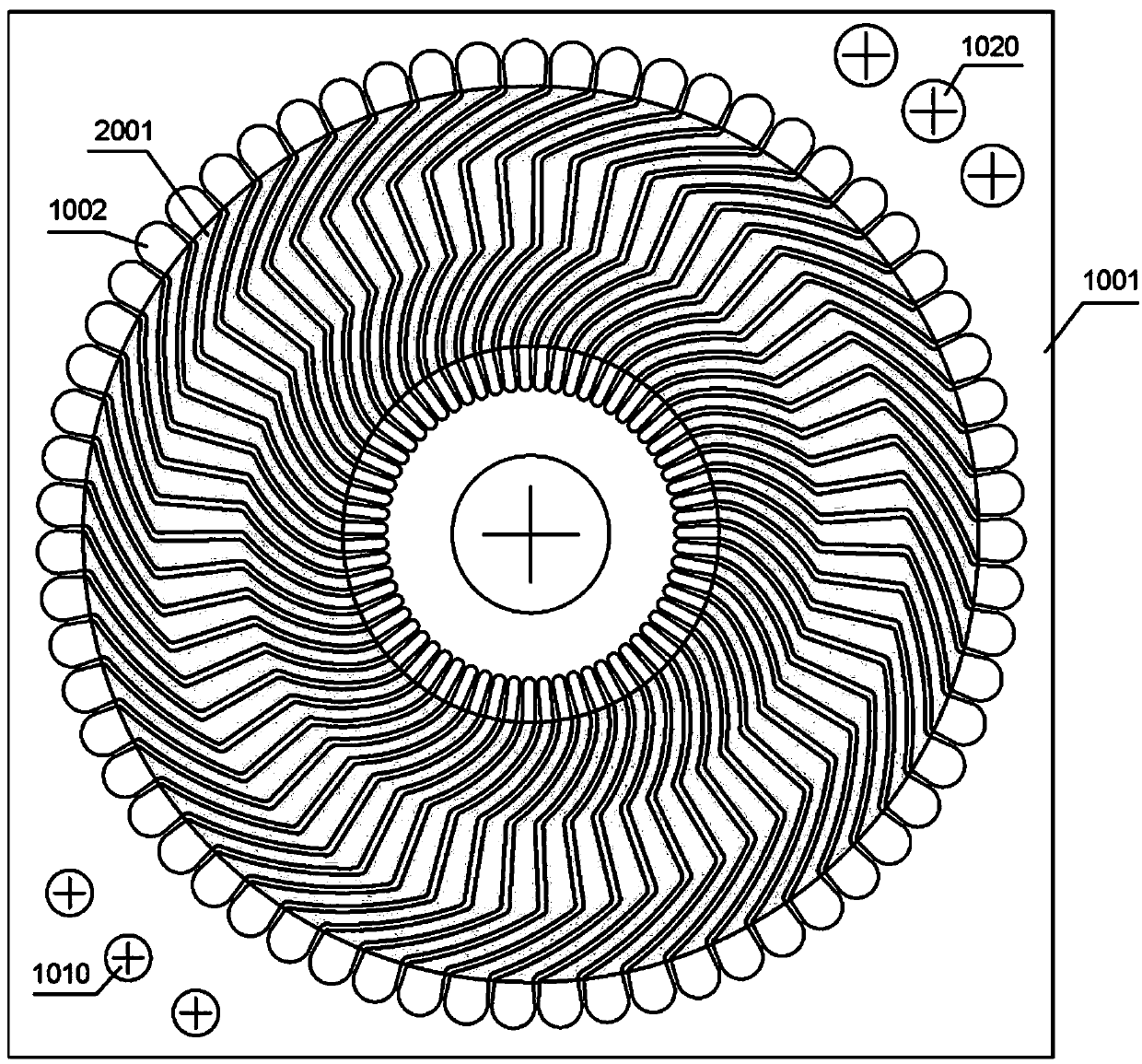

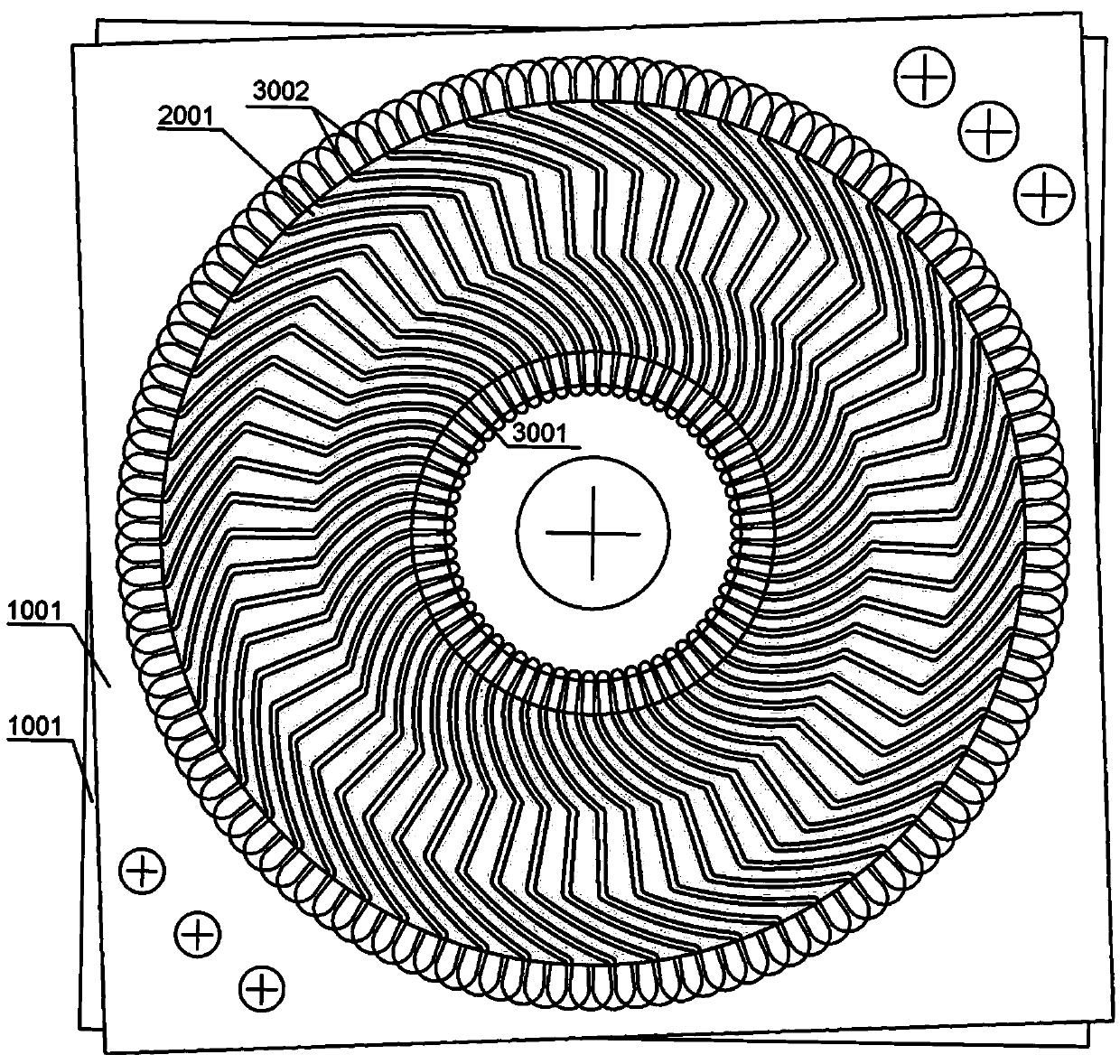

[0030] The three-phase symmetrical printed winding in this example is composed of 4 (M=1 in 4M) conductor sheets containing 63 (N=21 in 3N) conductors overlapped.

[0031] In order to describe the product in detail and accurately, this example explains from the perspective of product production.

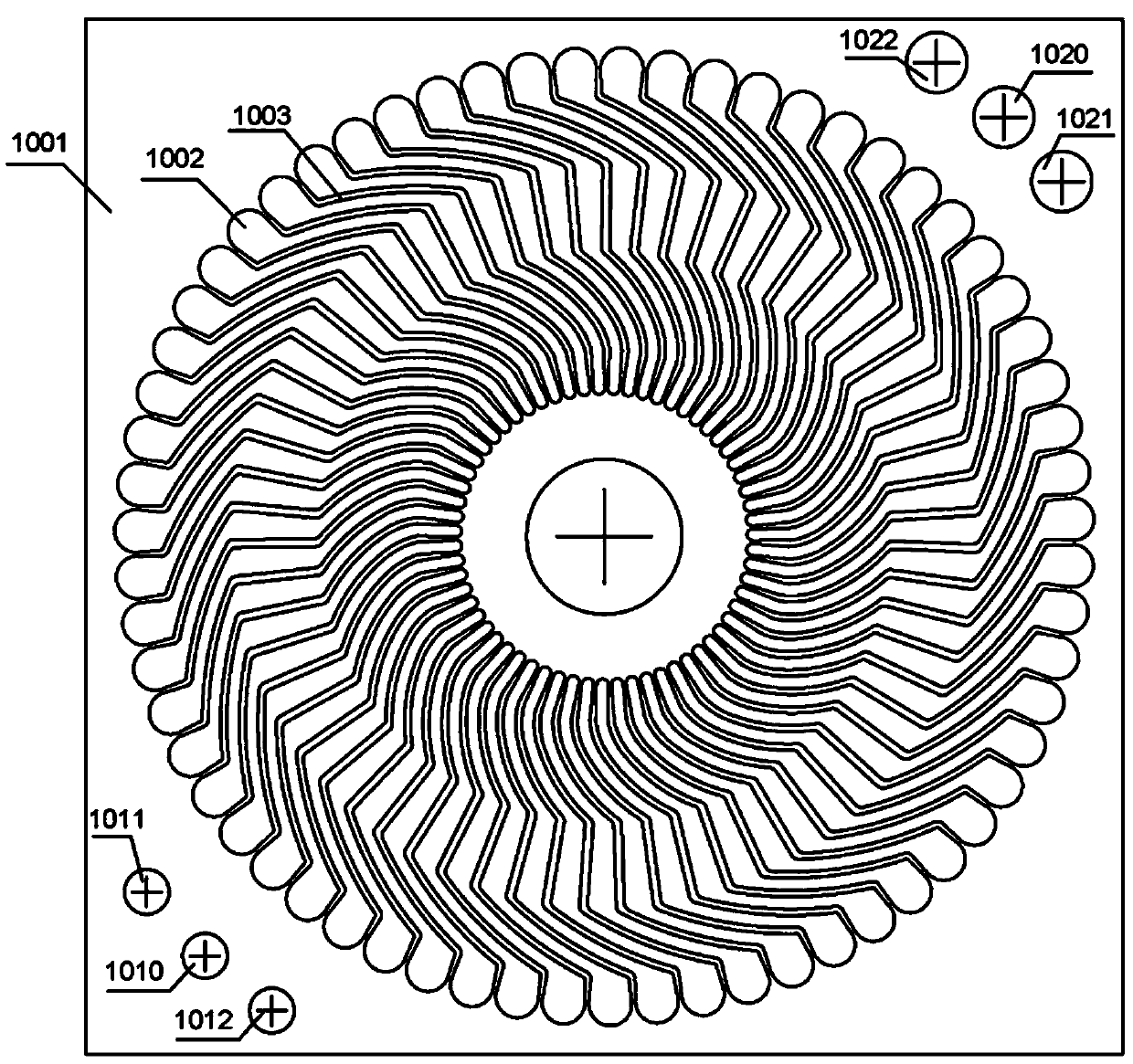

[0032] 1. Making punching film: such as figure 1 As shown, on a uniform copper alloy sheet with a thickness of 0.3 mm, a stamping sheet 1001 is produced by using a die or chemical etching. There are 3N punching grooves 1002 evenly distributed on the punching sheet 1001, and these punching grooves 1002 are evenly distributed around the axis and have the same shape. Three small-diameter positioning holes 1010, 1011 and 1012 are located in the lower left corner, and three large-diameter positioning holes 1020, 1021 and 1022 are located in the upper right co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com