Method for relieving annular belt pressure of natural gas and gas storage well

An annular pressure, gas storage technology, which is applied to earth-moving drilling, wellbore/well components, etc., can solve problems such as increased workload, rising management costs, and leakage of packer protection fluid production areas, reducing The effect of the number of replenishments and the reduction of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

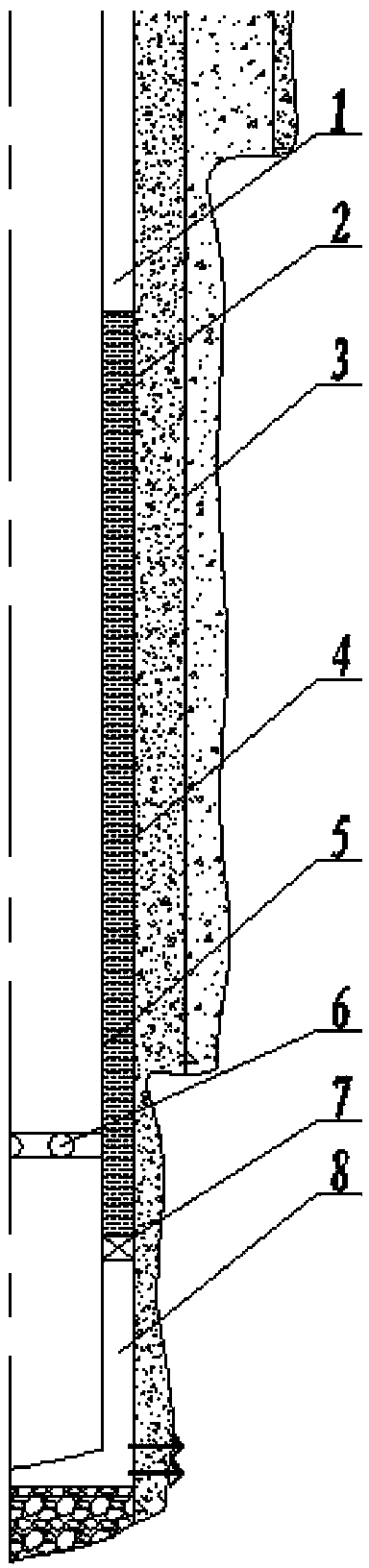

[0016] Embodiment 1: as figure 1 as shown,

[0017] figure 1 It is a schematic diagram of the position of each component after the implementation of the present invention. In the figure, the inert gas (nitrogen) 1 is above the protective liquid 2, the technical casing 3 wraps the production casing 4, the production casing 4 wraps the oil pipe 5, and the sliding sleeve 6 connects the oil pipe 5. Packer 7 isolates natural gas (production fluid) 8 and protection fluid 2. In fact, it is an inert gas (nitrogen) 1 of a certain length and pressure. In this section, the protection fluid 2 is replaced to prevent the protection fluid 2 from returning to the wellhead.

[0018] 1) Before implementation, understand the pressure of the target layer in the natural gas or gas storage well area, the well structure used, the size of the production casing, the size of the tubing, the structure of the completion string, the state of the wellhead, the performance of the protective fluid and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com