Expansion tube expansion process method and tool system

An expansion tube and tool technology, which is applied in the field of expansion tube expansion process and tool system, can solve problems such as inability to make threaded connections, failure to obtain the maximum diameter, and difficulty in realizing pressure chambers, so as to improve safety reliability and drilling speed, Dealing with drilling risks and accidents, reducing the effect of raw material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

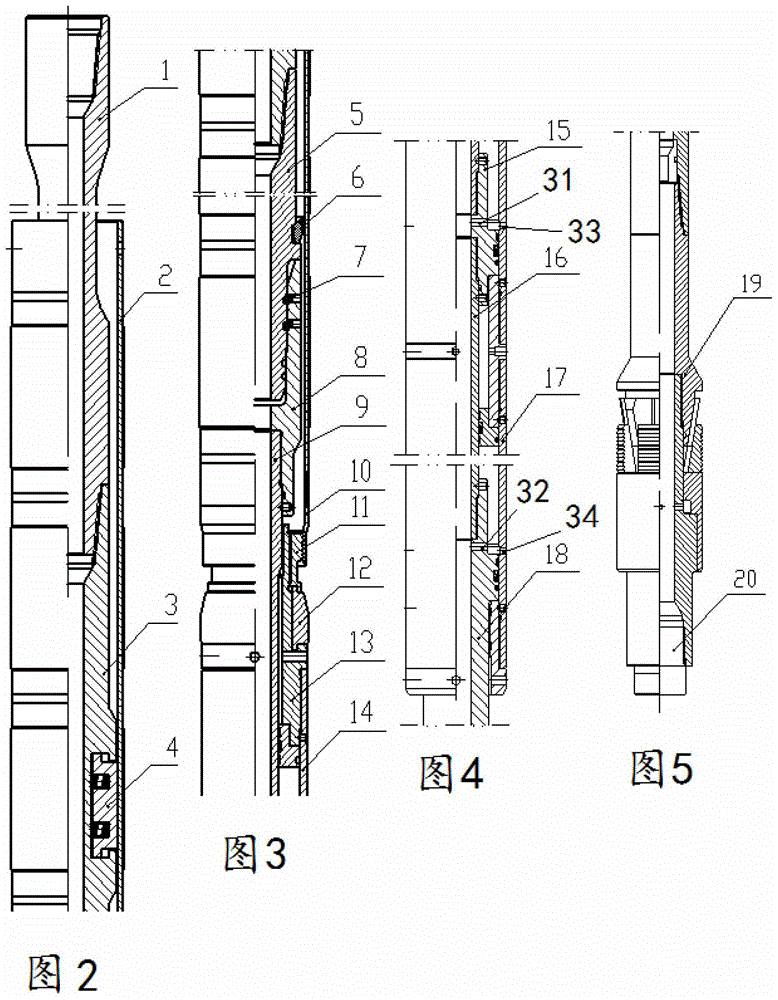

[0030] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an expansion tool system, the outer surface of the expansion tube vulcanizes rubber sleeves and steps at a certain distance. The rubber sleeve can make the expansion tube better adaptable to the open hole wall and enhance the fit of the expansion tube to the open hole wall. The steps enhance the fit and suspension of the expansion tube.

[0031] The expansion joint in the expansion tube assembly is located at the bottom end of the expansion tube, and is connected to the expansion tube through a common threaded port, and the other end is connected to the connection compression sleeve with a negative-angle partial ladder left-hand thread buckle, and the expansion cone can be released after expansion.

[0032] The center rod assembly is made up of three identical center rods, stoppers and springs. There are three groups of stoppers on each center rod, and each group distributes four sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com