Drilling interval variable-diameter spiral drill pipe for soft-hard composite coal seam

A soft-hard composite and helical drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of low drilling efficiency, shallow drilling depth, frequent drilling accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

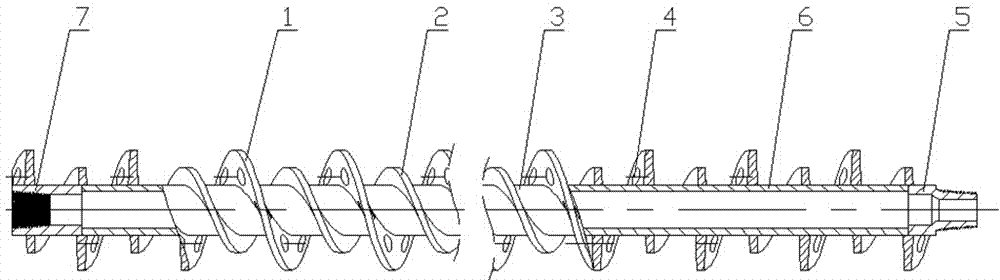

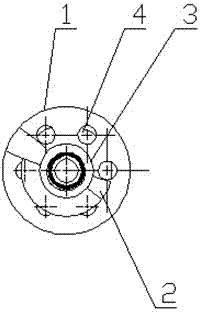

[0016] Embodiment one: if figure 1 , figure 2 As shown, the variable-diameter helical drill rod used for drilling intervals in soft and hard composite coal seams of the present invention includes a high helical blade 1, a low helical blade 2, and a drill pipe body 3, and the high helical blade 1 and the low helical blade 2 are fixed on the On the drill pipe body 3. The high helical blade 1 is designed in two ways: no air hole 4 or air hole 4 is provided. The height of the low helical blade 2 is lower than that of the high helical blade 1, and the height of the high helical blade 1 is 2 to 10 times that of the low helical blade 2. The drill pipe body 3 is composed of a female joint 7, an intermediate rod body 6, and a male joint 5. The female joint 7 and the male joint 5 are connected to both ends of the intermediate rod body 6. The female joint 7 and the male joint 5 are designed to be threaded or plugged in.

[0017] The following introduces the principle of embodiment on...

Embodiment 2

[0020] Embodiment two: if Figure 4 , Figure 5 As shown, the difference from Embodiment 1 is that the connection mode of the drill pipe joint is changed. The female joint 12 and the convex joint 11 are designed as a hexagonal structure, and a pin hole 13 is designed on one side, and the convex joint 11 is provided corresponding to the pin hole 13. groove 14.

Embodiment 3

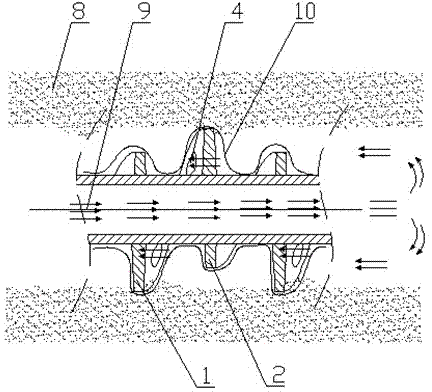

[0021] Embodiment three: as Image 6 As shown, the difference from Embodiment 1 and Embodiment 2 is that the cross-sectional shape of the vent hole 4 on the high helical blade 1 is changed, and a larger area of slag discharge channel is formed between the vent holes 4 of the high helical blade 1, which can The effect of pressure-assisted slag removal can be more fully exerted, and the drilling effect of spaced and variable-diameter auger drill pipes in soft-hard composite coal seams can be better utilized in areas with serious drilling deformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com