Venue giant arch structure high-altitude inclination deflection lifting method

A technology for arch structures and venues, which is applied in the direction of building structure, construction, and building material processing, and can solve problems such as quality, safety, and construction period cannot be effectively guaranteed, high quality and safety risks, and difficult welding, etc., to reduce installation costs. The effect of construction difficulty, construction period guarantee, construction safety and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be further described below in conjunction with the drawings and embodiments of the present invention.

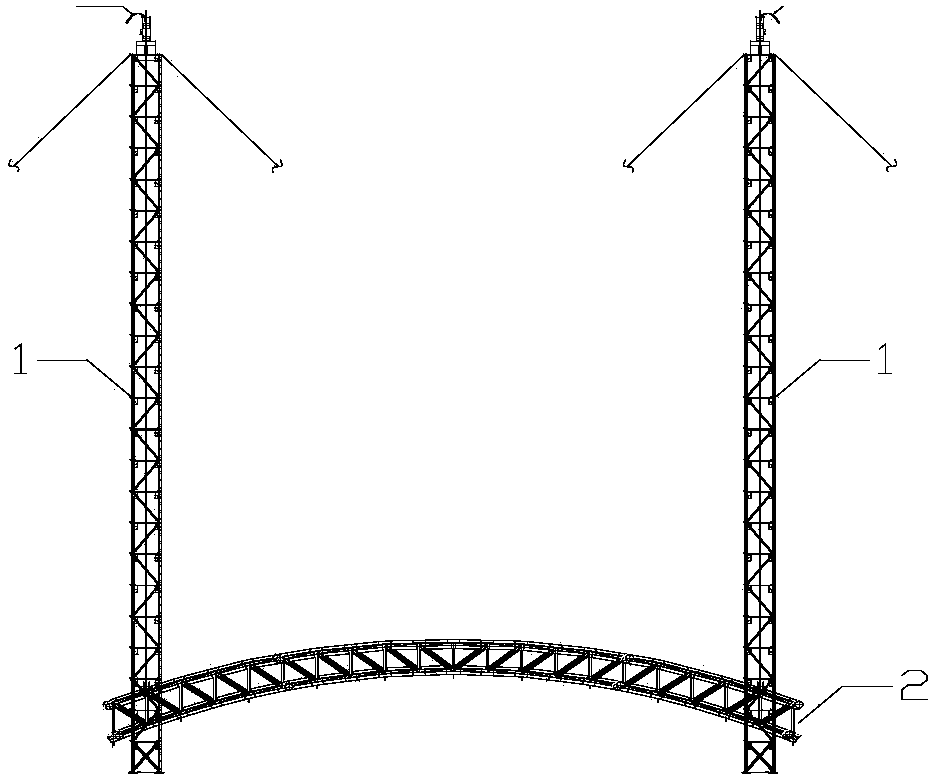

[0029] This embodiment is the hoisting construction process of a giant arch in a stadium of a national fitness activity center, such as figure 1 As shown, its construction steps are as follows:

[0030] Such as figure 2 As shown, the preparatory work before lifting is completed, including hydraulic system, lifter, tower installation, cable wind rope installation and other preparations are in place.

[0031] After the preparatory work before lifting is completed, the giant arch will be hoisted. The hoisting of the giant arch adopts computer synchronous lifting control. In order to ensure the safety of the hoisting process of the giant arch structure, according to the characteristics of the giant arch structure, the "hoisting point oil pressure balance, structural attitude adjustment, displacement synchronization control,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com