Progressive collapse preventing design method for failure of prestressed cables in string tensioning structure of building system

A technology of prestressed cables and design methods, applied to building components, special structures, calculations, etc., can solve problems such as loss of bearing capacity and stability, uneconomical and reasonable, and failure to consider component stability requirements, etc., to achieve a reasonable and light structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

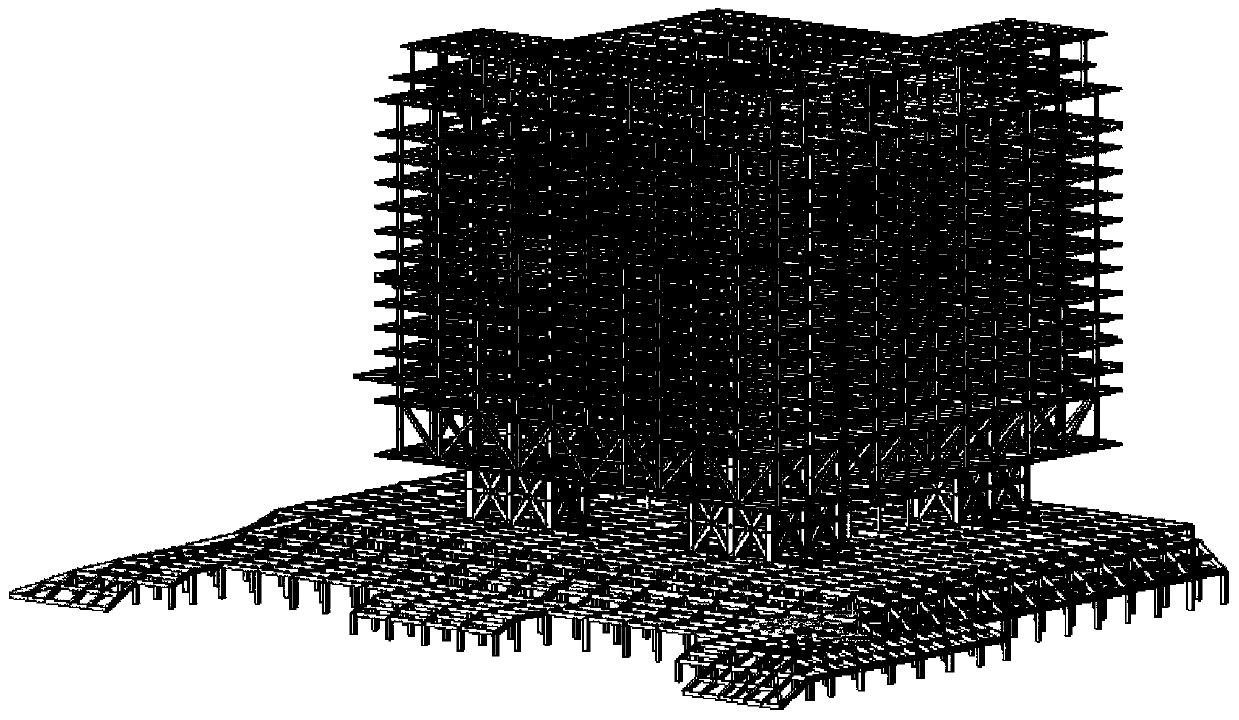

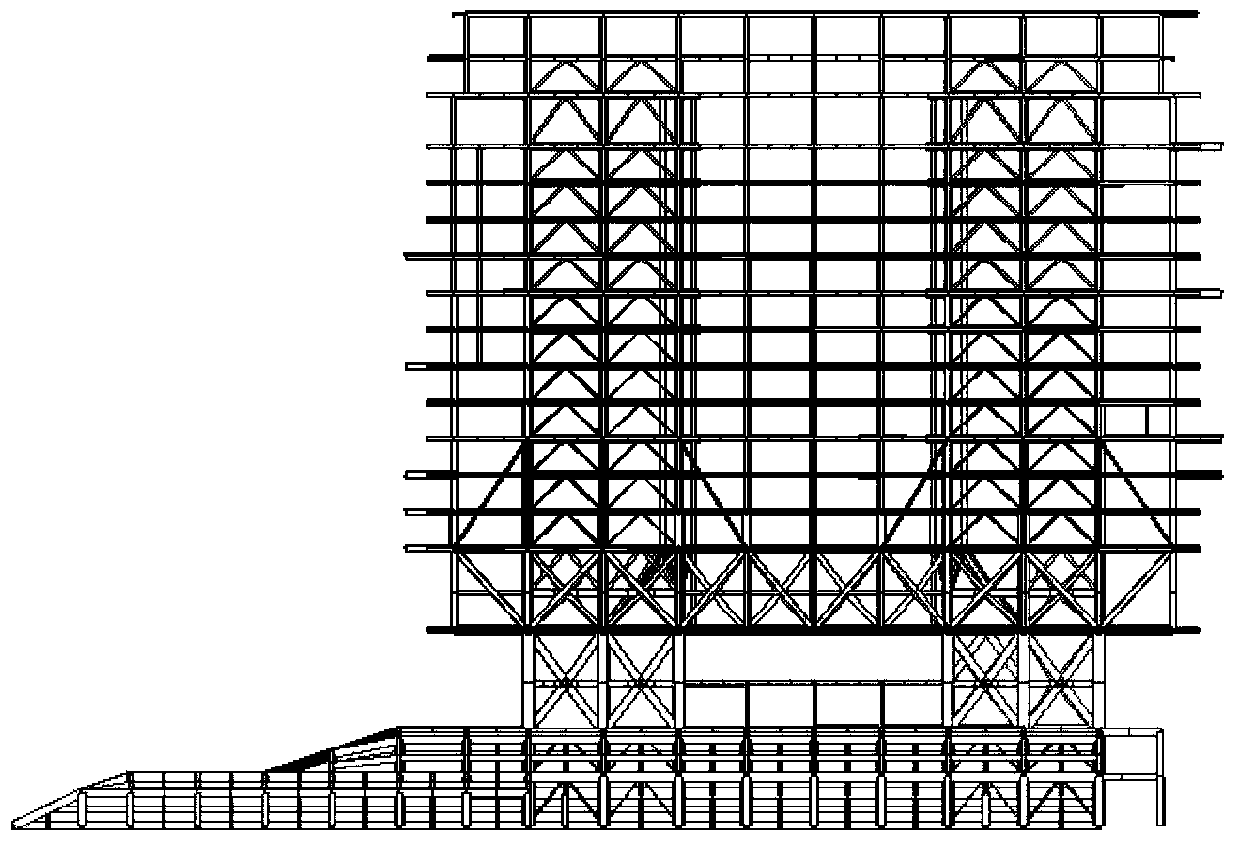

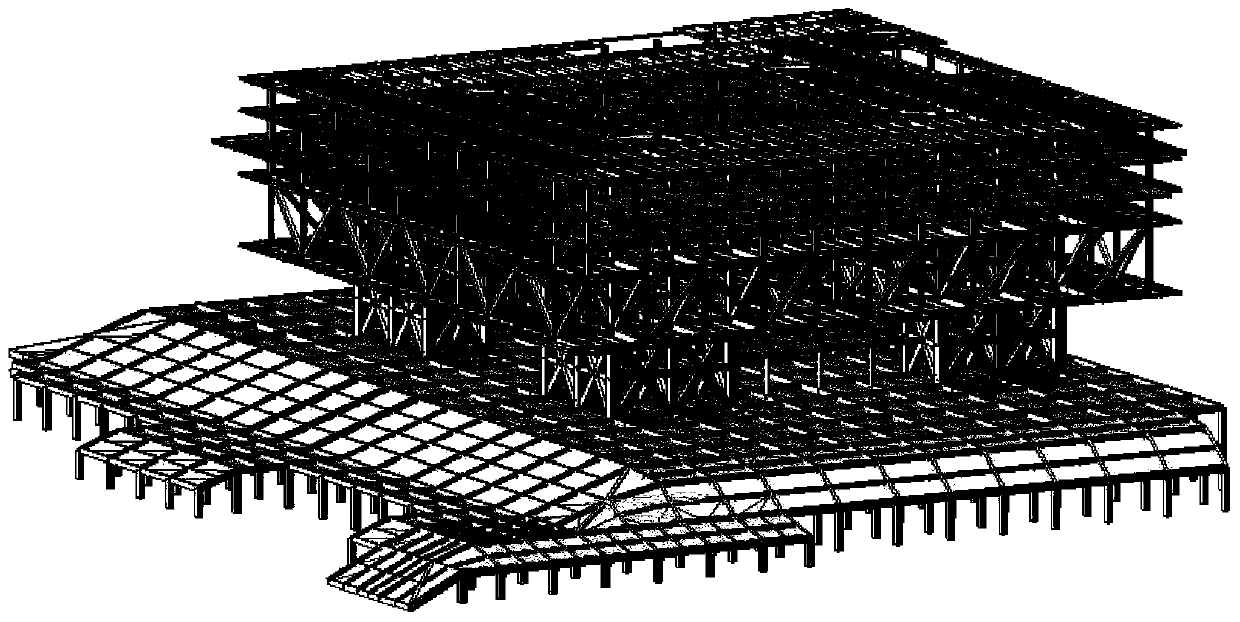

[0074] In the following, the progressive collapse design method of the present invention will be described in detail in conjunction with the structural model using the progressive collapse design method of the present invention. For the structural model drawing of the design method for preventing progressive collapse of the present invention, please refer to figure 1 and figure 2 . The concrete process of the anti-progressive collapse design method of the present invention is as follows:

[0075] 1. Analysis model establishment and selection

[0076] Establish an analysis model to obtain the initial state and response of the string structure: According to the static load analysis of the original structure, the finite element model of the string structure is established on the finite element simulation computing platform, and the continuous collapse analysis of the structure is carried out, that is, when the building suffers After accidental loads lead to sudden failure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com