High-damping composite stay cable based on carbon fibers and steel strands

A steel strand and high damping technology, applied in the field of stay cables, can solve the problems of increasing the wind resistance stability of the stay cables, high cost of use, and difficult construction, etc. Construction, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

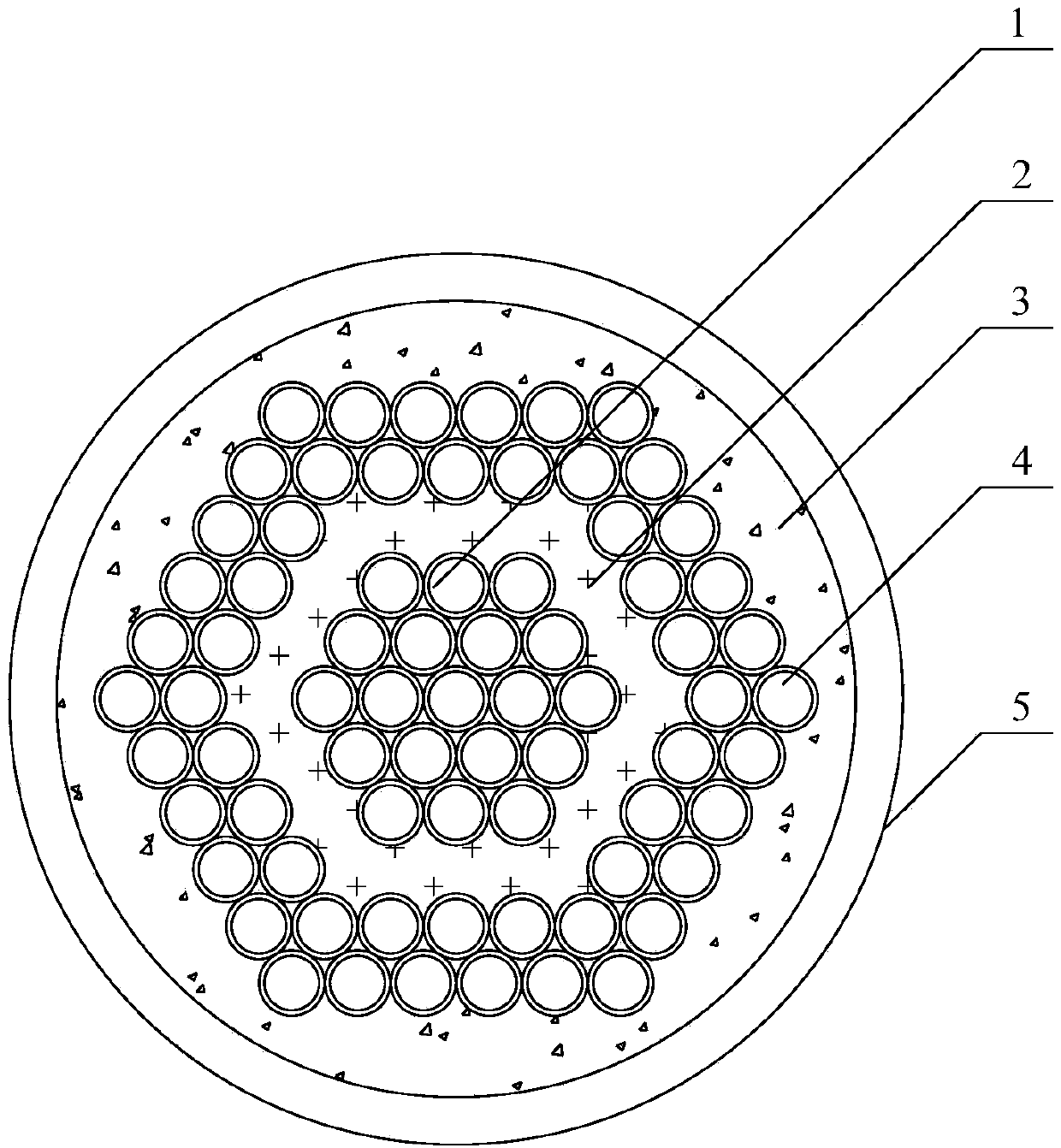

[0027] see figure 1 As shown, the embodiment of the present invention provides a high-damping composite stay cable based on carbon fiber and steel strands, including a core layer 1, 2-4 composite layers 4 and 1-2 layers of sheaths arranged in sequence from inside to outside 5. The sheath 5 is made of high-density polyethylene. The viscoelastic damping material 2 is filled between the core layer 1 and the composite layer 4, and the wear-resistant material 3 is filled between the composite layer 4 and the sheath 5, and the wear-resistant material 3 is basalt fiber, aramid fiber or glass fiber.

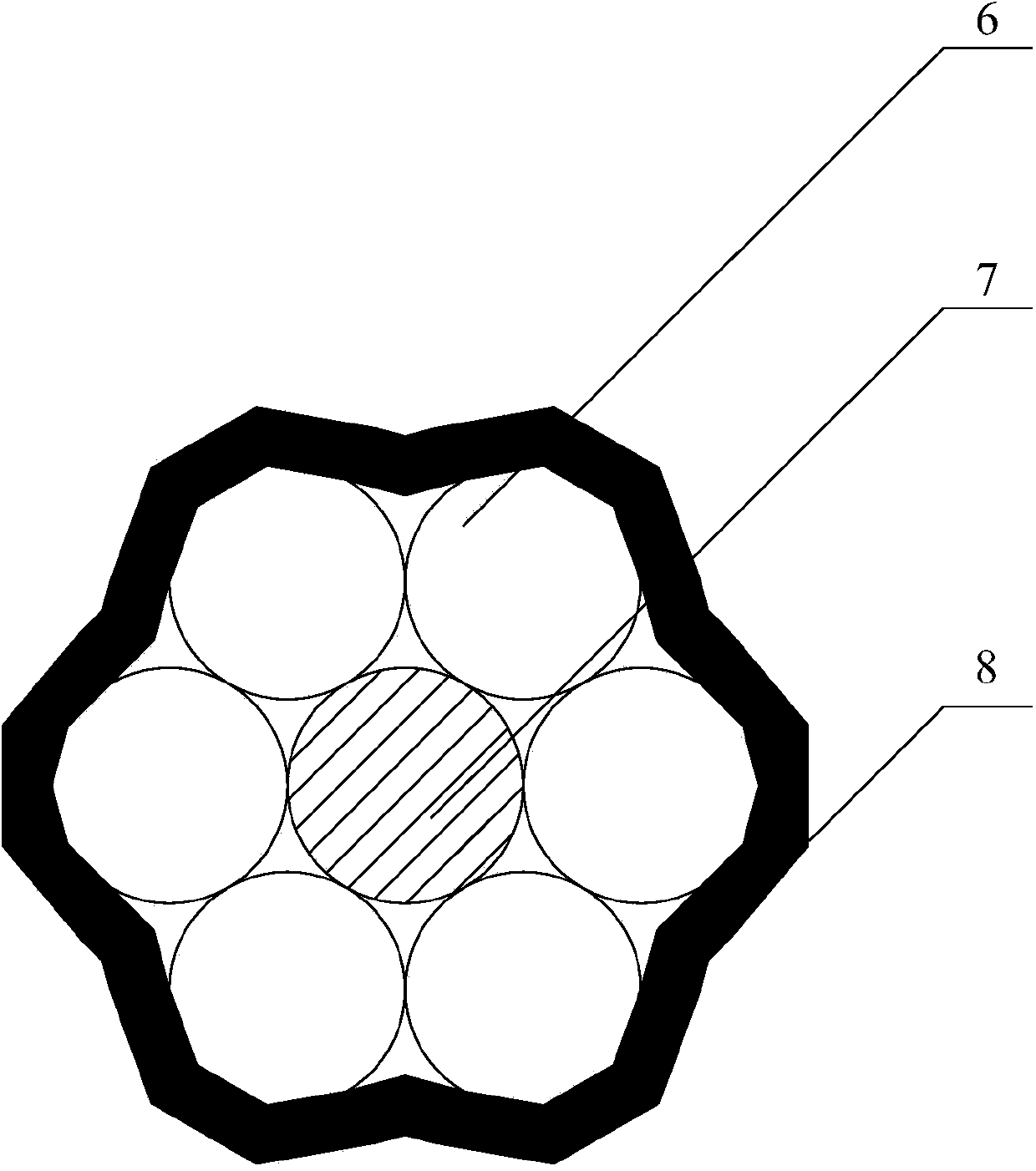

[0028] The cross section of the core layer 1 is a regular hexagon. The core layer 1 is composed of several high-strength steel strands closely arranged. The diameter of the high-strength steel strands is 1-10mm, for example: 1mm, 2mm, 3mm, 4mm, 5mm, 6mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com