One-step chemical preparation method for graphene and polyaniline composite materials

A composite material, polyaniline technology, applied in the field of one-step chemical preparation of graphene/polyaniline conductive composite materials, can solve the problems of toxicity of hydrazine hydrate reducing agent, difficulty in industrial production, complicated preparation process, etc., to save preparation cost , reduced operation steps, simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

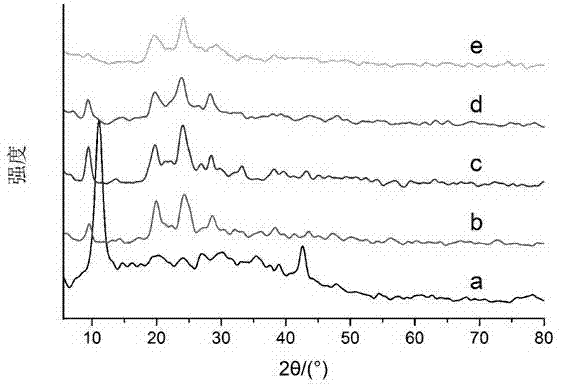

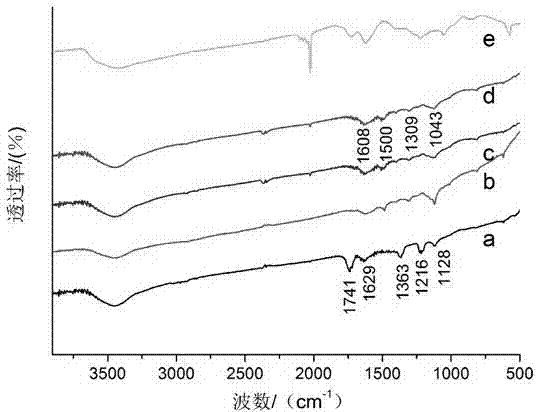

[0023] A one-step chemical preparation method of graphene / polyaniline composite material: add 50 mg of graphite oxide into 100 ml of acetic acid aqueous solution, fully stir and dissolve, prepare a graphite oxide-acetic acid solution with a concentration of 0.5 mg / ml, and then add 2.5 g of aniline monomer (The mass ratio of graphite oxide and aniline is 1:50), and ultrasonically disperse for 15 minutes to mix the graphite oxide and aniline monomer evenly. Then add 2ml of hydroiodic acid aqueous solution reducing agent (the volume ratio of hydroiodic acid to acetic acid is 1:50) to the graphite oxide / aniline mixed solution, and slowly add 12.5g of ammonium persulfate aqueous solution with a mass fraction of 10% (per The mass ratio of ammonium sulfate to aniline is 1:2), and the magnetic stirring is continued. The polymerization reaction was carried out in an ice bath at 0°C for 4h. After the reaction was finished, the product was suction-filtered, washed repeatedly with deioni...

Embodiment 2

[0025] A one-step chemical preparation method of graphene / polyaniline composite material: add 200mg of graphite oxide into 100ml of acetic acid aqueous solution (concentration is 38%), fully stir and dissolve, prepare graphite oxide-acetic acid solution with a concentration of 2mg / ml, and then add 5g of aniline monomer (the mass ratio of graphite oxide and aniline is 1:25), and ultrasonically disperse for 60min, so that the graphite oxide and aniline monomer are evenly mixed. Then add 3.3ml of hydroiodic acid reducing agent aqueous solution (the volume ratio of hydroiodic acid to acetic acid is 1:30) to graphite oxide / aniline mixed solution, and slowly add 33g of ammonium persulfate aqueous solution (per The mass ratio of ammonium sulfate to aniline is 2:1), and the magnetic stirring is continued. The polymerization reaction was carried out in a water bath at 30°C for 12h. After the reaction was finished, the product was suction-filtered, washed repeatedly with deionized wate...

Embodiment 3

[0027] A one-step chemical preparation method of graphene / polyaniline composite material: add 500mg of graphite oxide into 100ml of acetic acid aqueous solution (concentration is 37%), fully stir and dissolve, prepare graphite oxide-acetic acid solution with a concentration of 5mg / ml, and then add 2.5g of aniline monomer (mass ratio of graphite oxide and aniline is 1:5), and ultrasonically disperse for 120min to mix graphite oxide and aniline monomer evenly. Then add 10ml of hydroiodic acid aqueous solution reducing agent (volume ratio of hydroiodic acid aqueous solution to acetic acid aqueous solution is 1:10) in graphite oxide / aniline mixed solution, and slowly add 25g mass fraction to be 50% ammonium persulfate aqueous solution ( The mass ratio of ammonium persulfate to aniline is 5:1), and the magnetic stirring is continued. The polymerization reaction was carried out in a water bath at 60°C for 24h. After the reaction was finished, the product was suction-filtered, washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com