Expanding agent clinker granule sieving and conveying machine

A technology of expansion agent clinker and conveyor, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increasing production cost of expansion agent, low production efficiency, laborious labor and so on, and achieves improvement of production environment, reduction of dust, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

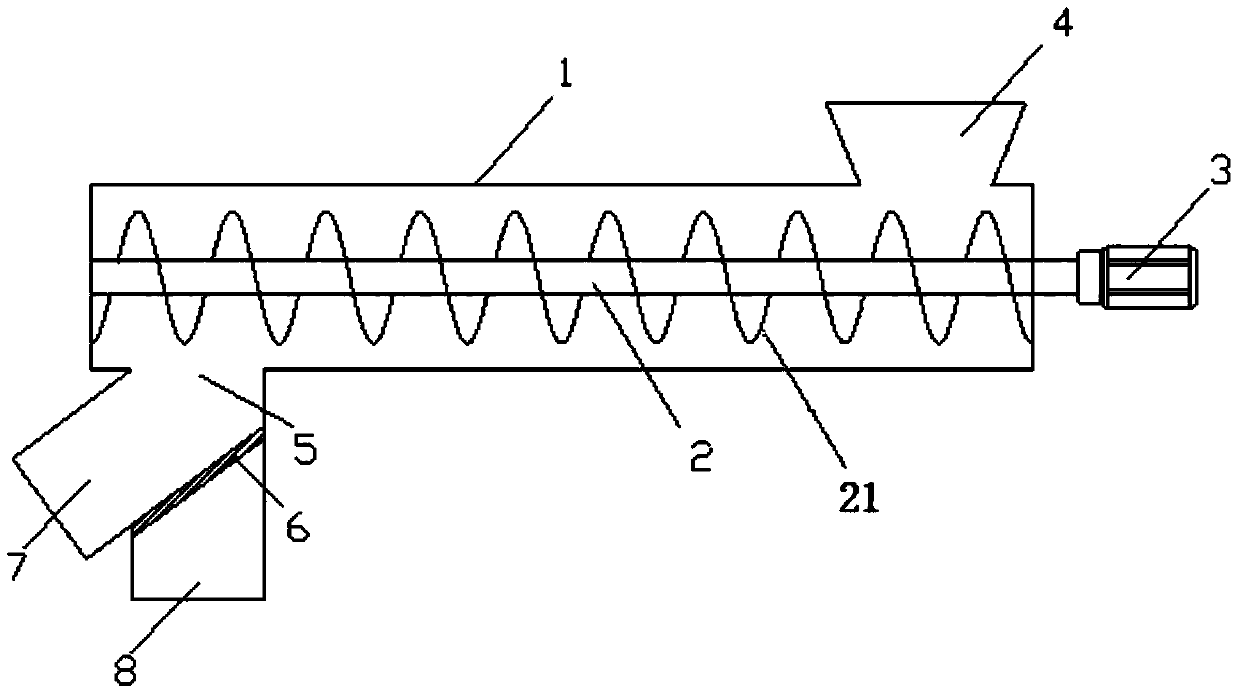

[0012] A preferred embodiment 1 of a kind of expansion agent clinker particle screening conveyor of the present invention, as figure 1 As shown, it includes a hollow tube shell 1, a screw pusher shaft 2 arranged inside the tube shell 1, and a variable frequency motor 3 that drives the screw pusher shaft 2 to rotate around its axis, the tube shell 1 and the screw pusher The axis lines of the shaft 2 are coincident, and the screw pushing shaft 2 is provided with blades 21 for pushing materials, and the blades 21 form a spiral structure around the screw pushing shaft 2, and one end of the tube shell 1 is provided with an expansion agent. The feed port 4 connected to the discharge port of the clinker granule production equipment, the other end of the shell 1 is provided with a discharge port 5, and the bottom of the discharge port 5 is provided with a vertically downward first discharge port 8 and The second discharge port 7 obliquely downwards, the bifurcation of the first discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com