Surface finishing technology of paper packing box

A packing box and process technology, applied in printing device, printing post-processing, printing, etc., can solve problems such as slow production rate, environmental pollution, and difficult film degradation, and achieve exquisite packaging, avoid pollution, and prevent surface scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

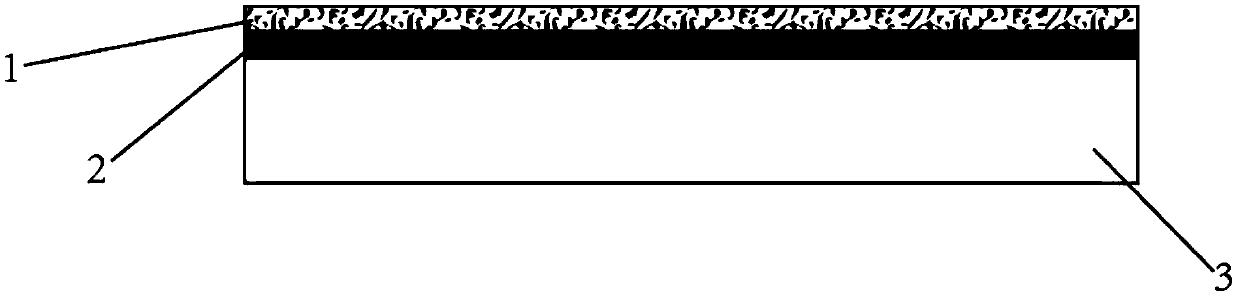

Image

Examples

Embodiment 1

[0056] Take a cosmetic packaging box as an example to use screen printing for surface finishing:

[0057] The paper of the cosmetic packaging box is 300g / ㎡ white cardboard. The paper surface of the packaging box is printed with patterns and texts by offset printing process. After printing, it is bronzing and embossed. The paper surface is not printed with varnish or film.

[0058] After the pattern and text are printed, use a screen printing machine to coat a layer of Lishi ink on the paper surface of the cosmetic packaging box. Among them, the components and the weight of the components of Lizan ink are: sodium calcium borosilicate 70g; silicon dioxide 9g; titanium dioxide 9g; iron oxide 11g; tin oxide 1g. Choose 200 mesh mesh for the screen plate used for coating LEISON ink. When coating, avoid the bronzing and concave-convex parts on the surface of the printed matter that do not need to be decorated with Lisan. At the same time, based on the crease line, do not apply Lisan...

Embodiment 2

[0062] Take a cosmetic packaging box as an example to use screen printing for surface finishing:

[0063] The paper of the cosmetic packaging box is 300g / ㎡ white cardboard. The surface of the paper of the packaging box is printed with patterns and texts by gravure printing process. After printing, it is bronzing and embossed.

[0064] After the pattern and text are printed, use a screen printing machine to coat a layer of Lishi ink on the paper surface of the cosmetic packaging box. Among them, the components and weights of the Lishen ink are: sodium calcium borosilicate 54g; silicon dioxide 15g; titanium dioxide 14g; iron oxide 16g; tin oxide 1g. Choose 100 mesh mesh for the screen plate used for coating LEISON ink. When coating, avoid the bronzing and concave-convex parts on the surface of the printed matter that do not need to be decorated with Lisan. At the same time, based on the crease line, do not apply Lisan ink within the width of 2mm on both sides.

[0065] Use ult...

Embodiment 3

[0068] Take a cosmetic packaging box as an example to use screen printing for surface finishing:

[0069] The paper of the cosmetic packaging box is 300g / ㎡ white cardboard. The paper surface of the packaging box is printed with patterns and texts by offset printing process. After printing, it is bronzing and embossed. The paper surface is not printed with varnish or film.

[0070] After the pattern and text are printed, use a screen printing machine to coat a layer of Lishi ink on the paper surface of the cosmetic packaging box. Among them, the components and the weight of the components of Lizan ink are: sodium calcium borosilicate 87g; silicon dioxide 3g; titanium dioxide 4g; iron oxide 6g; tin oxide 0g, no tin oxide is added. Choose 300 mesh mesh for the screen plate used for coating LEISON ink. When coating, avoid the bronzing and concave-convex parts on the surface of the printed matter that do not need to be decorated with Lisan. At the same time, based on the crease li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com