Ink path pressure self-balancing ink loading device for inkjet photo machine and using method thereof

A self-balancing, photo machine technology, applied in printing and other directions, can solve problems such as burnt nozzles, differences in understanding, disconnection, etc., and achieve standardized operation and long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

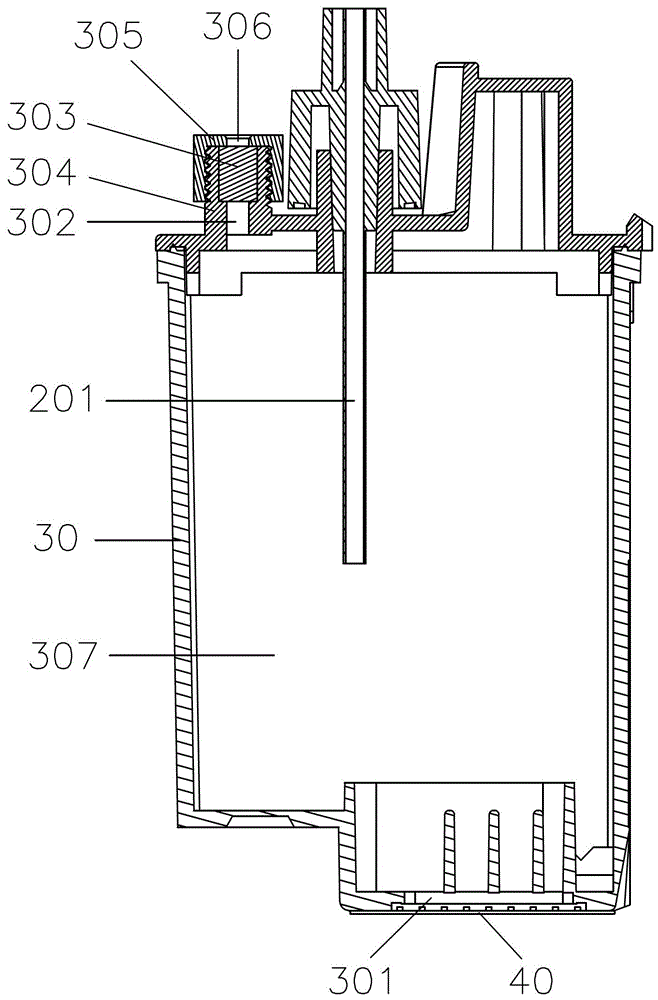

[0020] refer to figure 1 As shown, the present invention discloses an ink-jet photo machine ink path pressure self-balancing nozzle ink loading device, the ink-jet photo machine ink path pressure self-balancing nozzle ink loading device is installed on the nozzle of the inkjet photo machine, and multiple nozzles are loaded side by side After installation, you can print out drawings with different needs. refer to figure 1 and figure 2 As shown, it includes an ink supply tank 10 and an ink delivery tube 20 connected at one end to the ink supply tank 10 for supplying ink. The other end of the ink delivery tube 20 is connected to a nozzle box 30 and extends through the ink needle Into the interior of the nozzle box 30 , the ink supply chamber 10 has an ink supply port 101 communicating with the outside atmosphere, and the bottom of the nozzle box 30 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com