Nano fluid micro lubrication electrostatic atomization controllable jet turning system

A micro-lubrication and electrostatic atomization technology, which is used in metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc. It can solve the problems of large size of electrostatic atomization nozzle, inability to use internal cooling turning, and low precision. , to achieve the effect of improving the lubrication and cooling effect, improving the utilization rate, and reducing the amount of drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention is described below in conjunction with accompanying drawing.

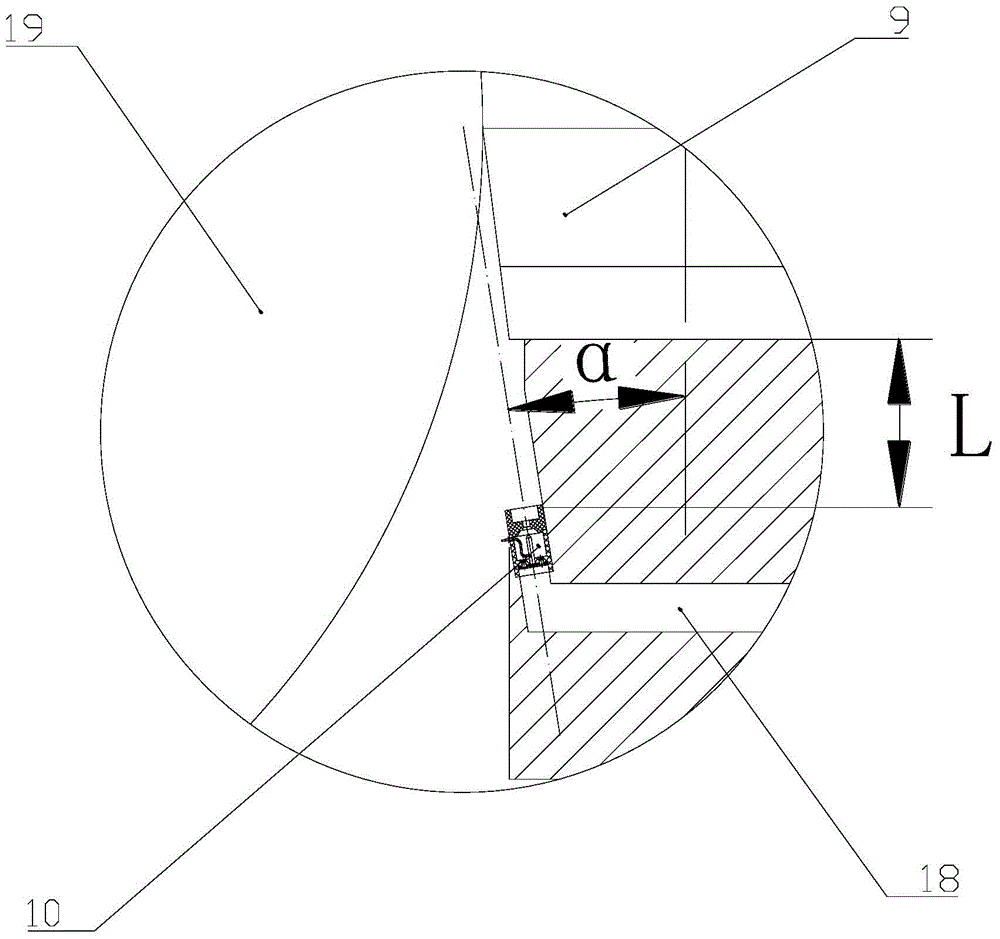

[0065] Such as figure 1 shown, combined with figure 2 , Nano fluid micro-lubricating electrostatic atomization controllable jet turning system includes adjustable multi-negative power supply 1, internal cooling turning tool 5, built-in integrated nozzle 10, and external integrated nozzle 11. The adjustable multi-negative power supply 1 has two negative interfaces of different voltages (negative interface I14, negative interface II15) and one positive interface 16, and the voltages of the two negative interfaces are adjustable without affecting each other. The adjustable multi-negative power supply 1 transmits negative electricity to the built-in integrated nozzle 10 through the negative wire I12, and the interface of the adjustable multi-negative power supply 1 is the negative interface II15; the adjustable multi-negative power supply 1 transmits negative electricity to the external i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com