Flexible Fixtures for Vertical Assembly of Large Thin-walled Cylindrical Members

A thin-walled cylinder, flexible fixture technology, used in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of low clamping efficiency, difficulty in ensuring the geometric shape of the cylinder, and complicated operations, so as to improve assembly efficiency, The effect of reducing uncontrollable factors and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

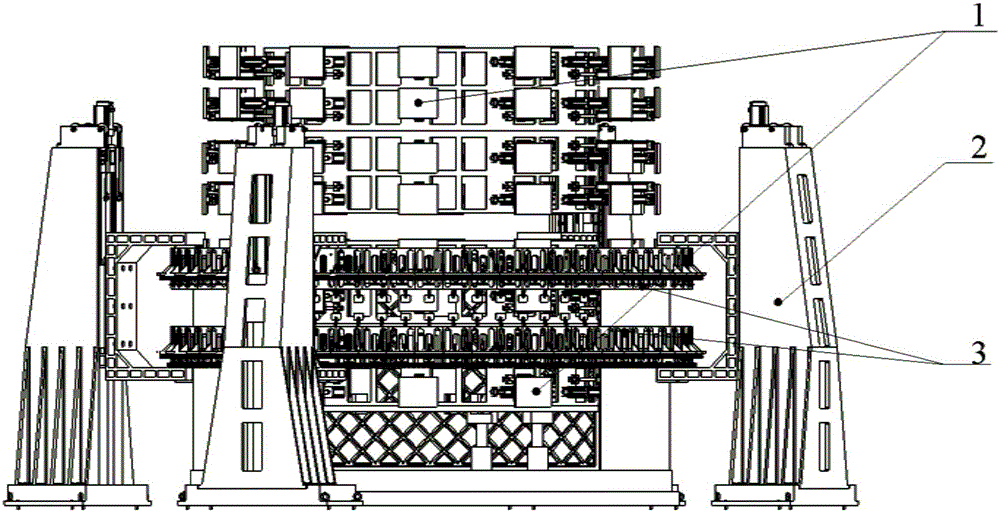

[0032] Such as figure 1 As shown, this embodiment includes: an array of internal support fixtures 1, a support structure 2, and an array of external pressure fixtures 3, wherein: the array of internal support fixtures 1 is fixed on the ground, and the array of external pressure fixtures 3 is supported on the support structure 2, four The supporting structures 2 are evenly distributed along the circumference.

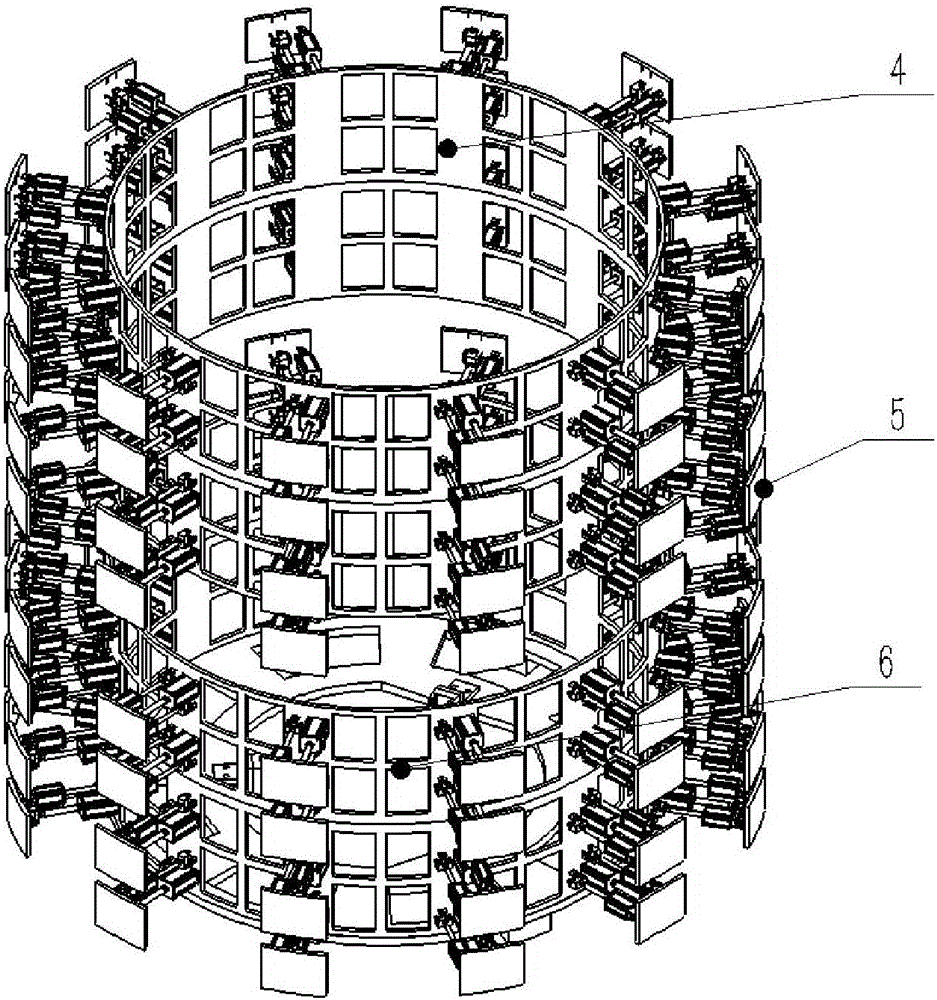

[0033] Such as figure 2 As shown, the inner support fixture array 1 includes: an upper inner support fixture array 4, a lower inner support fixture array 6 and a three-degree-of-freedom support mechanism, wherein: the upper inner support fixture array 4 and the lower inner support fixture array are composed of multiple A group of circularly arranged three-degree-of-freedom support mechanisms are used to apply support force inside the thin-walled cylindrical member and adjust the magnitude and direction of the force.

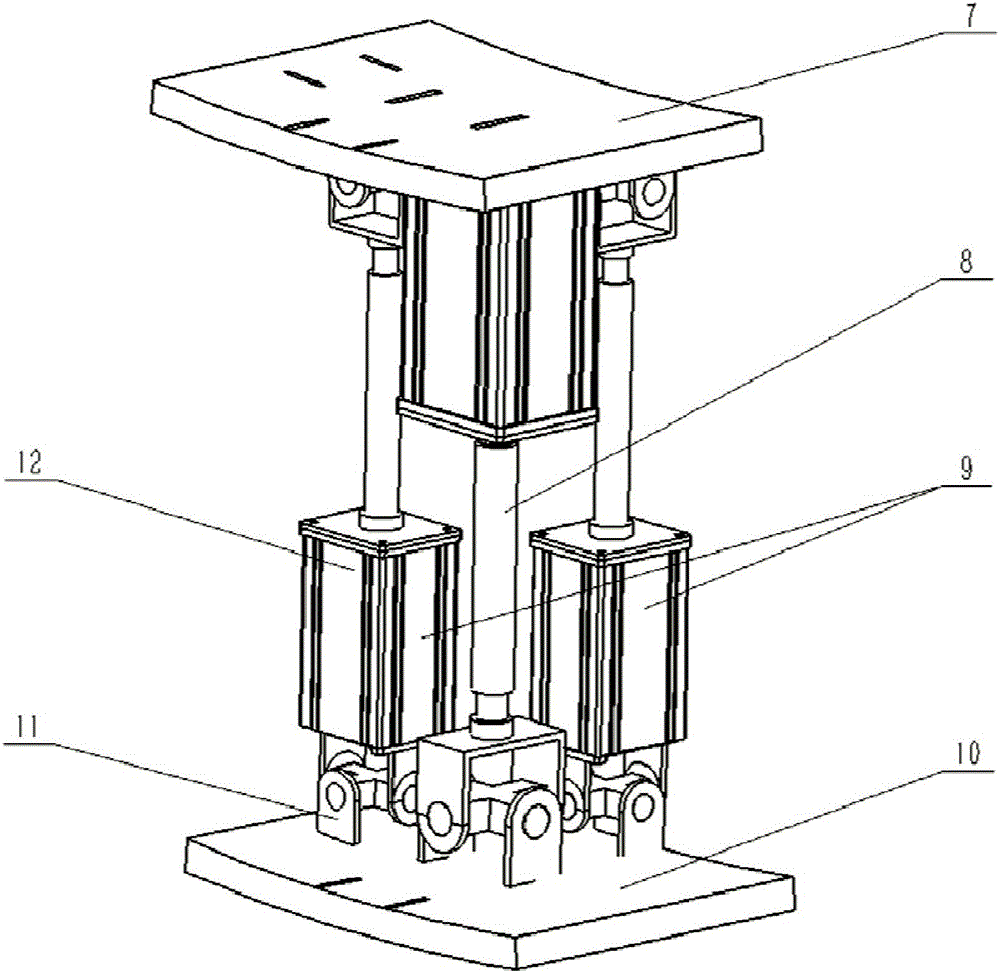

[0034] Such as image 3 As shown, the three-degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com