Lathe for manufacturing suction roll drum of paper machine

A technology of vacuum roll and paper machine, which is applied to the lathe of paper machine and the lathe of paper machine vacuum roll drum, can solve the problems of difficulty in returning and changing the knife, low dynamic balance, shortening the service life of the vacuum roll, etc. , Eliminate the effect of low dynamic balance and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

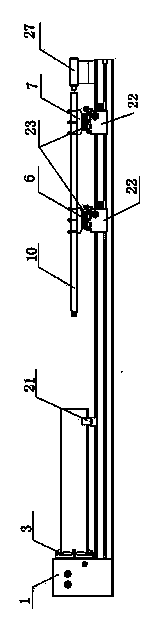

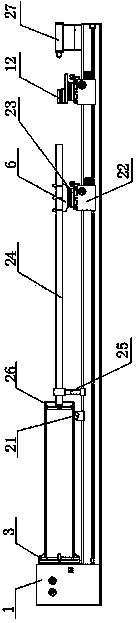

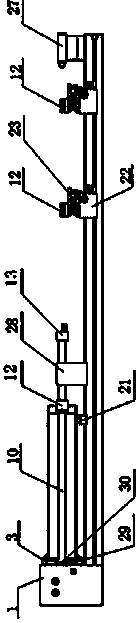

[0017] Such as Figure 4 Shown is a structural diagram of the present invention, a lathe for making a paper machine vacuum roll, which specifically includes the following structure: headstock 1, main shaft 2, chuck 3, first lathe bed 4, second lathe bed Body 5, first knife rack 6, second knife rack 7, first knife rack carriage 8, second knife rack carriage 9, knife rack 10, guide rail 11, knife rack holder 12, knife rack Tool rest feeding device 13 and workpiece center bracket 14; described main shaft 2 and chuck 3 are hollow structures, main shaft 2 is placed in headstock 1, and headstock 1, main shaft 2 and chuck 3 are placed in the lathe In the middle; the first knife rack 6 is placed above the first lathe bed 4, the second knife bank 7 is placed above the second lathe bed 5, and the workpiece center bracket 14 is placed above the second lathe bed 5; The above-mentioned first knife rack dragging plate 8 is placed above the first knife rack 6, and the second knife rack drag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com