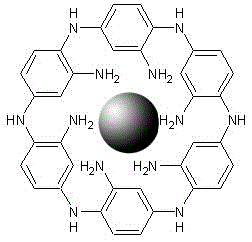

A kind of poly-o-phenylenediamine-nanometer metal composite particle and its preparation method

A poly-o-phenylenediamine and nano-metal technology, which is applied in the direction of coating, etc., achieves the effect of preventing agglomeration, preventing loss, and the preparation method is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The steps of the preparation method of poly-o-phenylenediamine-nano metal composite particles are as follows:

[0032] 1) In an ice bath environment, dissolve 0.002-0.006mol metal nitrate in 20-80mL dispersion-stabilizer solution with a mass percent concentration of 2%-8%, and use mechanical stirring to make the above mixed solution foam and foam The amount is 5 times of the volume of the dispersion-stabilizer solution, take 0.001-0.005mol reducing agent and dissolve it in ice water, after the dissolution is complete, drop the reducing agent solution dropwise into the metal nitrate-dispersing agent solution, so that the Metal ions are completely transformed into metal elements;

[0033] 2) After the above reaction is complete, add the reaction solution in step 1) to a centrifuge tube, and perform centrifugation at 2000r / min for 2-4min, dilute the obtained colloidal metal 100 times and conduct ultraviolet analysis to verify the synthesis of nano-metal particles ;

[00...

Embodiment 1

[0040] 1) Dissolve 0.002mol of copper nitrate in 20mL of 8% polyvinyl alcohol solution in an ice bath environment. Use strong mechanical stirring to make the above mixed solution foam, and the foaming amount is 5 times of the volume of the polyvinyl alcohol dispersion-stabilizer solution. Take 0.001mol sodium borohydride and dissolve it in ice water. After the dissolution is complete, the sodium borohydride solution is dropped dropwise into the copper nitrate-polyvinyl alcohol solution, so that the copper ions in the reaction solution are completely converted into simple copper.

[0041] 2) After the above reaction is complete, add the reaction solution in step 1) to the centrifuge tube, perform centrifugation at 2000r / min for 2min, dilute the obtained colloidal metal 100 times, and conduct ultraviolet analysis to verify the synthesis of nano-copper particles;

[0042] 3) Take 0.0005mol o-phenylenediamine and add it to 1mol / L hydrochloric acid solution, sonicate it to dissolv...

Embodiment 2

[0046]1) Dissolve 0.004mol of silver nitrate in 40mL of 4% polyethylene glycol solution in an ice bath environment. Use strong mechanical stirring to make the above mixed solution foam, and the foaming amount is 5 times the volume of the polyethylene glycol dispersion-stabilizer solution. Take 0.001mol sodium borohydride and dissolve it in ice water. After the dissolution is complete, the sodium borohydride solution is dropped dropwise into the silver nitrate-polyethylene glycol solution, so that the silver ions in the reaction solution are completely converted into simple silver.

[0047] 2) After the above reaction is complete, add the reaction liquid in step 1) to the centrifuge tube, perform centrifugation at 2000r / min for 3 minutes, dilute the obtained colloidal metal 100 times, and conduct ultraviolet analysis to verify the synthesis of nano-silver particles;

[0048] 3) Take 0.001mol o-phenylenediamine and add it to 1mol / L hydrochloric acid solution, sonicate it to dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com