Band steel traction connection structure and band penetration method for continuous band steel unit

A technology for connecting structures and traction belts, which is applied in the direction of bending workpieces, metal processing equipment, metal rolling, etc., can solve the problems of excessive tension of traction belts, broken belts, and low production efficiency, and prevent uneven distribution and ring formation The structure is firm and avoids the effect of excessive concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

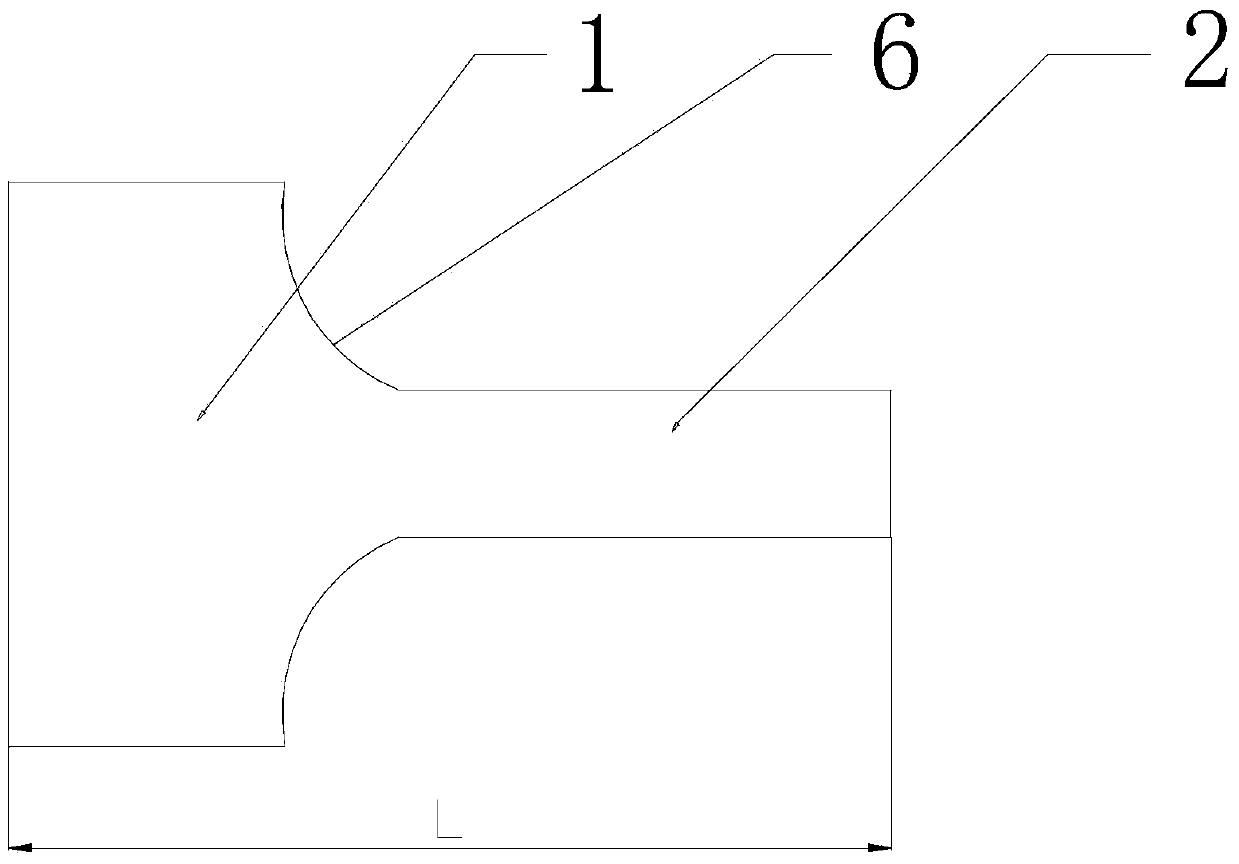

[0029] Such as figure 1 , figure 2 , image 3 ,and Figure 4 As shown, the strip steel traction connection structure adopted in the present invention comprises a strip steel end 1, a strip steel traction head 2, a pull ring 3 and a traction belt 4, and the two ends of the strip steel traction head 2 are connected to the strip steel end 1 connected to form a ring structure, one end of the pull ring 3 passes through the ring structure, and the other end is connected to the traction belt 4, one end of the strip steel traction head 2 is an integrated structure with the strip steel end 1, The other end is riveted on the strip end 1 . One end of the strip puller 2 is an integrated structure with the strip end 1, and the other end is riveted on the strip end 1, which can make the ring structure more reliable and is not easy to be connected by the pull ring 3 during the strip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Opening | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com