Method for roasting aluminum electrolytic tank with special-shaped cathode structure

A technology of aluminum electrolysis cell and cathode structure, which is applied in the field of aluminum electrolysis technology, and can solve problems such as rising unit energy consumption, affecting the economic benefits of production enterprises, and damage to aluminum electrolysis cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

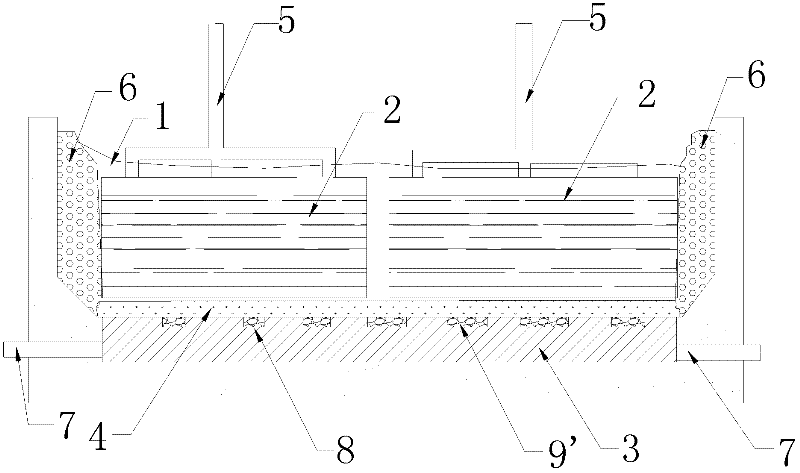

[0045] Roasting method

[0046] A. Fill the groove of the shaped cathode with cryolite, and the cryolite is not in contact with the anode;

[0047] B. Lay coke particles on the boss of the shaped cathode so that the coke particles contact the anode;

[0048] C. Add cryolite powder as insulation material, and energize and roast.

[0049] After roasting to meet the requirements, the electrolyte is added, the cryolite melts into the electrolyte, and the coke particles float on the surface of the electrolyte, and the electrolysis can be carried out after removing the floating layer.

[0050] Results: Roasting electricity consumption is 44560kwh, electricity cost is 22280 yuan, carbon residue is 365kg, and there is no sign of damage to the cathode within 1 year of start-up.

Embodiment 2

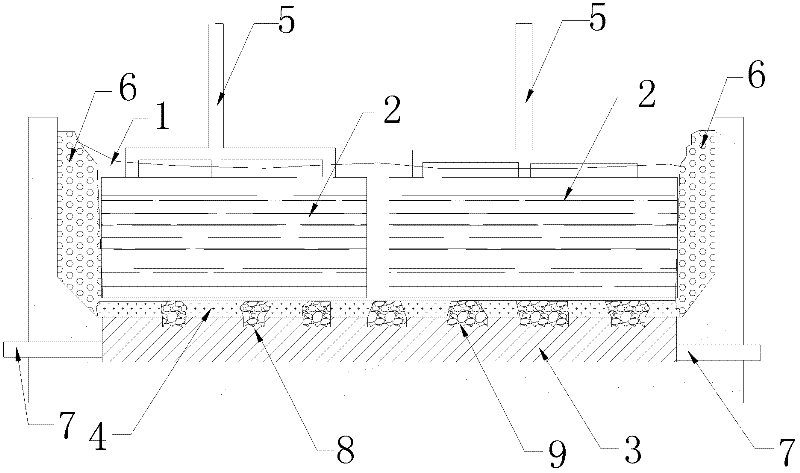

[0052] Roasting method

[0053] A. Fill the electrolyte block in the groove of the special-shaped cathode, and the electrolyte block is not in contact with the anode;

[0054] B. Lay graphite powder on the boss of the special-shaped cathode so that the graphite powder contacts the anode;

[0055] C. Add cryolite powder as insulation material, and energize and roast.

[0056] After roasting to meet the requirements, the electrolyte is added, the cryolite melts into the electrolyte, the graphite powder floats on the surface of the electrolyte, and the electrolysis can be carried out after removing the floating layer.

[0057] Results: Roasting electricity consumption is 43200kwh, electricity cost is 21600 yuan, carbon residue is 315kg, and there is no sign of damage to the cathode within one year of start-up.

Embodiment 3

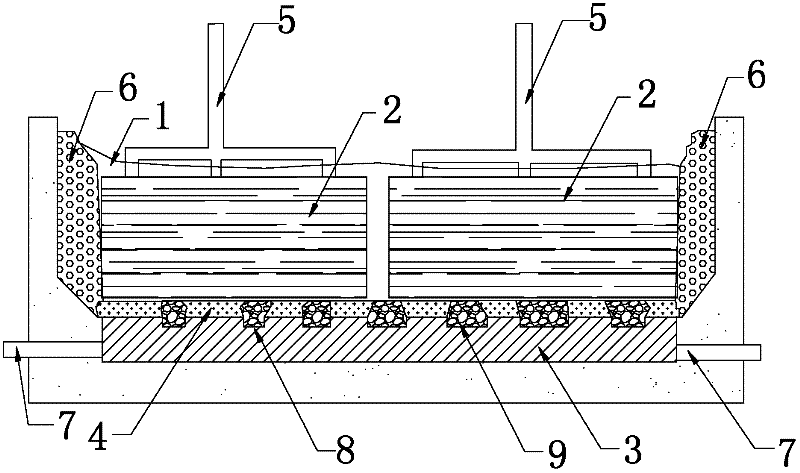

[0059] Roasting method

[0060] A. Fill electrolyte block and cryolite in the groove of special-shaped cathode, its weight ratio is 40% of electrolyte block, 60% of cryolite, make electrolyte block and cryolite contact anode;

[0061] B. Laying graphite powder and coke particles on the boss of the special-shaped cathode, the weight ratio is 40% of graphite powder and 60% of coke particles, so that the carbon material contacts the anode;

[0062] C. Add cryolite powder as insulation material, and energize and roast.

[0063] After roasting to meet the requirements, the electrolyte is added, the cryolite and the electrolyte block melt into the electrolyte, the carbon material floats on the surface of the electrolyte, and the electrolysis can be carried out after removing the floating layer.

[0064] Results: Roasting consumes 43900kwh of electricity, the electricity cost is 21950 yuan, the amount of carbon residue is 336kg, and there is no sign of damage to the cathode within 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com